In the rapidly evolving landscape of manufacturing and construction, Aluminum Tube Profiles have emerged as a critical component, driving innovations and enhancing performance across various industries. As we look ahead to 2025, the demand for lightweight, durable, and versatile materials is more pronounced than ever. This shift is prompting organizations to explore new technological advancements and applications for Aluminum Tube Profiles, leading to significant growth within the sector.

The focus on sustainability and efficiency has catalyzed a wave of creativity among manufacturers, resulting in cutting-edge designs and production methods that not only meet but exceed industry standards. Whether it’s through the integration of advanced fabrication techniques or the development of specialized coatings that improve corrosion resistance, the innovations surrounding Aluminum Tube Profiles are setting the stage for a transformative era in manufacturing.

In this overview, we will delve into the top five innovations that are driving the growth of Aluminum Tube Profiles, examining their implications for the industry and the potential opportunities they present for businesses looking to leverage these advancements. By understanding these key developments, stakeholders can better position themselves to harness the benefits of Aluminum Tube Profiles in their operations, ultimately paving the way for a more efficient and sustainable future.

Emerging trends in aluminum tube profiles for 2025 indicate a significant shift towards sustainable and high-performance materials. The global push for green technologies is leading manufacturers to innovate in the aluminum tube sector, focusing on eco-friendly production processes and materials that reduce environmental impact. Reports suggest that the green aluminum market is poised to expand beyond USD 220 billion, emphasizing the growing recognition of sustainability among consumers and industries alike.

To maximize the benefits of these innovations, companies are adopting advanced manufacturing techniques that enhance the strength-to-weight ratio and corrosion resistance of aluminum tubes. This not only improves product performance but also meets stringent regulatory standards for environmental safety. With Australia’s aluminum alloy tube market projected to reach 8.4K tons and $32 million by 2035, the region stands at the forefront of this transformation.

**Tip:** When investing in aluminum tube profiles, consider sourcing from manufacturers that prioritize sustainability and innovations in production methods. This can not only enhance your product offerings but also align your business with global environmental goals. Additionally, keeping abreast of market forecasts and trends can help you anticipate changes in demand, allowing for better strategic planning.

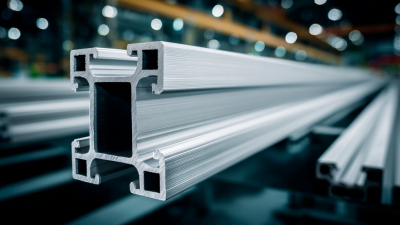

At the forefront of the aluminum industry innovations reshaping the landscape are breakthroughs in aluminum tube profiles, which are crucial for numerous applications, from automotive to construction. The AICE 2025 SMM Conference highlighted several key innovations, such as advanced extrusion techniques and the development of more sustainable alloys. These advancements not only enhance the performance and versatility of aluminum tubes but also align with the growing demand for environmentally friendly materials.

Furthermore, companies in the Asia-Pacific region are leveraging these innovations to expand their global footprint. By integrating innovative practices with cultural influence and strategic risk-taking, they are poised to become dominant players in the global aluminum market. This shift not only emphasizes the importance of continuous innovation but also showcases the region’s ability to adapt to changing industry dynamics, driving significant growth and competitiveness in the sector.

The aluminum tube manufacturing industry is witnessing a transformative shift towards sustainable practices, which are essential in driving both innovation and growth. The integration of eco-friendly methods not only enhances production efficiency but also minimizes environmental impact. Companies are increasingly adopting energy-efficient technologies and utilizing recycled aluminum, which significantly reduces carbon emissions associated with production processes. This commitment to sustainability resonates with consumers and manufacturers alike, as the demand for environmentally responsible products continues to rise.

In addition to recycling initiatives, advancements in green technologies are revolutionizing the aluminum tube production landscape. Innovative techniques such as using water-based coatings and reducing water usage in fabrication are gaining traction. These practices contribute to a diminished ecological footprint and promote a circular economy within the industry. As manufacturers prioritize sustainable solutions, they are not only responding to regulatory pressures but also positioning themselves as leaders in a rapidly evolving market. This proactive approach fosters long-term growth and resilience, making sustainable manufacturing a cornerstone of success in the aluminum tube sector.

The aluminum tube profile industry is experiencing significant innovations that are enhancing both design and functionality. According to a recent report by Market Research Future, the global aluminum extrusion market is expected to reach $200 billion by 2025, growing at a CAGR of 5.5%. This growth is largely driven by advancements in the manufacturing processes and the introduction of lightweight materials that improve structural integrity without compromising performance.

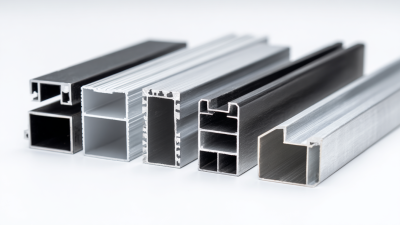

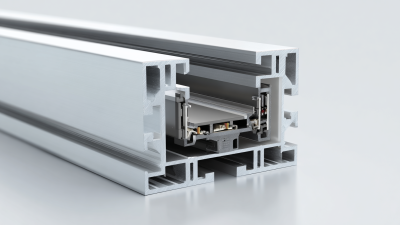

One of the most exciting developments is the use of advanced alloys that enhance strength while reducing weight. Notably, the incorporation of heat-treated alloys and surface treatments is revolutionizing the capabilities of aluminum profiles in various applications, from automotive to aerospace. Additionally, innovative design methodologies, such as 3D modeling and computer-aided design (CAD), are allowing for intricate designs that meet the specific needs of end-users.

**Tips:** When selecting aluminum tube profiles, consider the intended application and environmental factors. Ensure that the chosen profile has adequate corrosion resistance and meets weight restrictions. Collaborating with suppliers who utilize cutting-edge technology in their manufacturing processes can provide a competitive edge in performance and durability.

The advancements in technology have significantly transformed the performance and efficiency of aluminum tube profiles, making them a pivotal component in various industries. Innovations such as advanced extrusion techniques and precision machining have allowed manufacturers to produce aluminum tubes with enhanced strength-to-weight ratios, offering improved structural integrity without compromising on lightness. These enhancements contribute to better fuel efficiency in automotive applications and increased durability in construction projects.

Moreover, the integration of smart manufacturing technologies, such as automation and real-time data analytics, has streamlined production processes. This not only reduces waste but also optimizes resource utilization. Digital simulation tools are increasingly being employed to predict the behavior of aluminum tube profiles under different operating conditions, leading to more reliable and durable products. As industries continue to demand higher performance materials, these technological innovations in aluminum tube profiles are setting new benchmarks for efficiency and sustainability, driving significant growth in the sector.

| Innovation | Description | Impact on Performance | Efficiency Improvement (%) | Adoption Rate (%) |

|---|---|---|---|---|

| Lightweight Alloys | Use of advanced lightweight aluminum alloys to enhance strength-to-weight ratio. | Increased strength and reduced weight. | 20 | 50 |

| Corrosion-Resistant Coatings | Innovations in coating technology to protect aluminum tubes from corrosion. | Extended longevity and reduced maintenance costs. | 15 | 65 |

| Automated Manufacturing Processes | Implementation of automation to improve production efficiency and precision. | Higher accuracy with reduced human error. | 25 | 70 |

| 3D Printing of Aluminum Components | Utilizing additive manufacturing to create complex aluminum structures. | Enhanced design flexibility and reduced material waste. | 30 | 40 |

| Smart Aluminum Tube Profiles | Integration of sensors and IoT technology for real-time performance monitoring. | Improved operational insights and predictive maintenance capabilities. | 35 | 30 |