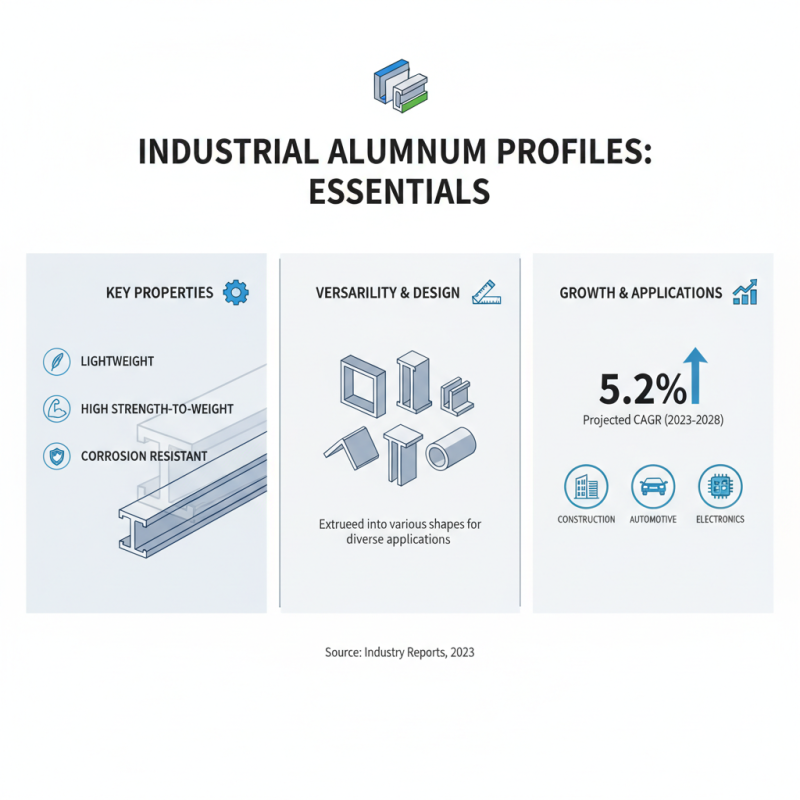

In the rapidly evolving landscape of industrial manufacturing, the choice of materials can significantly influence both the performance and sustainability of projects. Industrial Aluminum Profiles have emerged as a preferred solution due to their unique combination of lightweight strength, corrosion resistance, and versatility. According to a recent report by MarketsandMarkets, the global market for aluminum profiles is projected to reach $120 billion by 2025, growing at a CAGR of 5.3%. This growth underscores the importance of selecting the right profiles that not only meet the technical specifications of a project but also align with long-term strategic goals.

When it comes to choosing Industrial Aluminum Profiles, several factors must be considered, including the specific application, the mechanical properties required, and the environmental conditions the profiles will face. Industry experts suggest that thorough knowledge of these parameters can lead to improved efficiency, enhanced product lifespan, and reduced maintenance costs. Furthermore, with increasing emphasis on sustainability, selecting profiles that contribute to the circular economy is gaining traction, as highlighted by the European Aluminium Association, which states that aluminum can be recycled indefinitely without loss of quality. As such, understanding the intricacies of Industrial Aluminum Profiles is essential for making informed decisions that will drive project success and operational excellence.

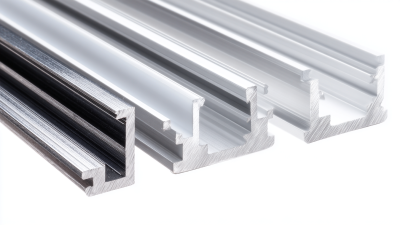

Industrial aluminum profiles are essential components in various engineering and manufacturing projects due to their lightweight nature, excellent strength-to-weight ratio, and corrosion resistance. Understanding the basics of these profiles is crucial for selecting the right materials for your specific applications. Aluminum profiles can be extruded into various shapes, allowing for great versatility in design and functionality. According to recent industry reports, the global demand for aluminum profiles is projected to grow at a CAGR of 5.2% over the next five years, driven by increasing usage in sectors such as construction, automotive, and electronics.

When choosing industrial aluminum profiles, consider the following tips: First, evaluate the mechanical properties required for your project. For instance, profiles intended for structural applications must meet specific strength and stiffness criteria. Second, pay attention to the surface treatment options available, as these can enhance durability and resistance to environmental factors. Anodizing, for instance, is a common technique that improves corrosion resistance significantly, making profiles suitable for outdoor applications. Lastly, it is important to match the aluminum alloy with the intended use; different alloys offer various benefits, such as improved weldability or enhanced strength.

Incorporating these tips can help streamline the selection process, ensuring that the aluminum profiles you choose not only meet your project requirements but also adhere to industry standards. Engaging with qualified suppliers who can provide insights and data about specific profiles can further optimize your decision-making process. By understanding these fundamentals, you can effectively utilize industrial aluminum profiles to enhance the performance and longevity of your projects.

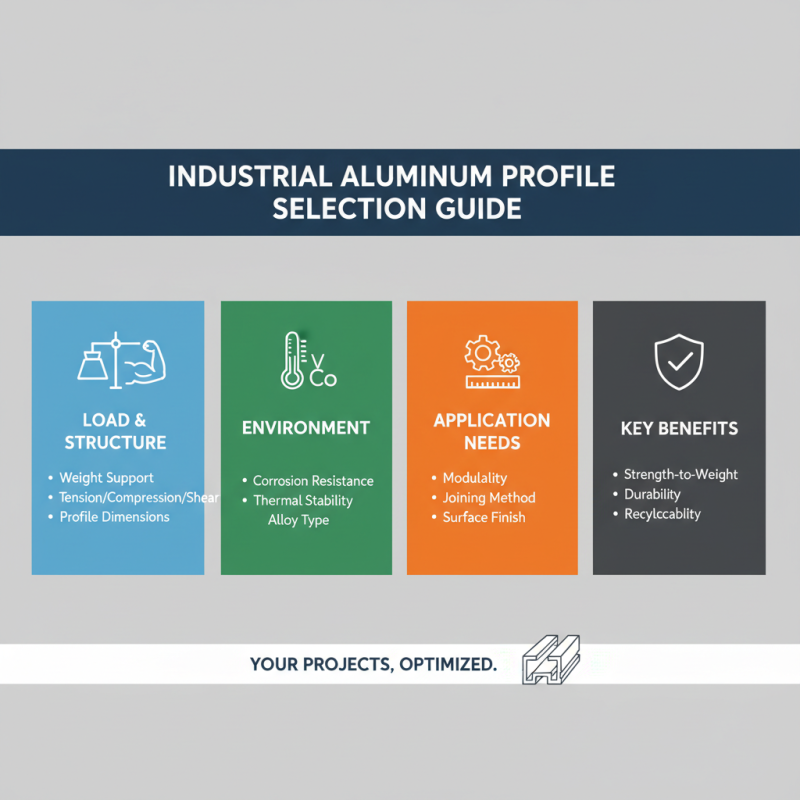

When selecting industrial aluminum profiles for your projects, understanding the specific requirements is crucial. Start by identifying the load-bearing capacity and structural demands of your application. This involves assessing the weight the profiles will need to support and the type of forces they will experience, such as tension, compression, or shear. It's essential to match the profile dimensions and alloy specifications with the expected environmental conditions, as certain alloys offer better corrosion resistance and thermal stability than others.

Additionally, consider the manufacturing processes and finishes available for the aluminum profiles. Depending on the intended use, you may need profiles that can be easily machined or that come with surface treatments for enhanced durability. Anodizing, for instance, can significantly increase the lifespan of the profiles in harsh settings. Evaluating these specifications will ensure that the aluminum profiles you choose not only meet the technical requirements of your project but also provide long-term performance and reliability.

When selecting industrial aluminum profiles for your projects, evaluating the quality and durability of these materials is crucial. According to a report by the Aluminum Association, high-quality aluminum profiles exhibit superior resistance to corrosion, with an average lifespan exceeding 30 years in harsh environments. This longevity is essential for reducing long-term maintenance costs and ensuring the structural integrity of your projects. Factors such as alloy composition, temper, and surface treatment play a significant role in determining the overall durability of aluminum profiles.

Tips: Always request detailed specifications from suppliers, focusing on the alloy series and temper rating, which indicate the strength and corrosion resistance of the profiles. It is also essential to consider the environmental conditions the profiles will be exposed to. Profiles with anodized finishes, for instance, can significantly improve resistance to abrasions and environmental wear compared to untreated options.

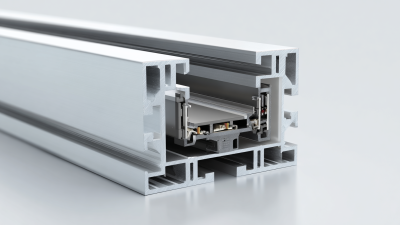

Another aspect to consider is the manufacturing process. A recent study from the International Journal of Engineering Research highlights that profiles produced through extrusion exhibit improved mechanical properties and are more uniformly shaped, leading to better performance in various applications. Therefore, understanding the production processes can help in selecting profiles that meet your project's demanding requirements.

When selecting industrial aluminum profiles for your projects, one of the cornerstone considerations is cost-effectiveness. Budget constraints can significantly influence your decision-making process, so it’s essential to strike a balance between quality and affordability. Prioritize suppliers that offer transparent pricing and a clear breakdown of costs, which can help you understand the overall financial implications before making a commitment.

One effective tip is to clearly define your project requirements before sourcing aluminum profiles. By having specific dimensions, weight capacities, and applications in mind, you can avoid overspending on unnecessary features. Additionally, consider bulk purchasing or collaborating with other businesses to negotiate better rates. This can not only reduce individual expenses but may also lead to favorable terms from suppliers.

Another important aspect is to research and compare different suppliers. Look for those who provide a variety of profiles to suit different applications without compromising quality. Online reviews and testimonials can offer valuable insights into their reliability and the performance of their products. Keep an eye out for promotions or discounts that can make a significant difference in your project's overall cost, ensuring that you stay within budget while still achieving your design goals.

When selecting a reliable supplier for industrial aluminum profiles, it's crucial to consider various factors that can significantly impact your project's success.

According to a recent industry report by the Aluminum Association, the global consumption of aluminum is projected to reach approximately 80 million metric tons by 2025, highlighting the material's growing demand in various sectors, including construction, automotive, and aerospace. This surge means that suppliers need to not only maintain high production standards but also ensure a steady supply chain to meet client requirements.

Evaluating a supplier’s credentials is essential in determining their reliability. Look for certifications such as ISO 9001, which indicates a commitment to quality management standards. Additionally, assessing the supplier’s production capabilities is crucial; those who can produce custom profiles to meet specific project needs often demonstrate advanced technology and expertise.

The ability to deliver on time, as supported by a 2023 report from MarketsandMarkets that states on-time delivery is a top criterion for 75% of buyers, can significantly influence your decision. Furthermore, checking references and past project success can provide insights into the supplier's reliability and performance in real-world applications.