When selecting Aluminum Tube Profiles for your projects, it’s essential to make informed decisions. Industry expert John Richards once stated, "Choosing the right profile is key to project success." This emphasizes the importance of understanding your specific requirements.

Aluminum Tube Profiles come in various shapes and sizes. Each option brings unique benefits and potential challenges. Ensure you consider the intended application and load requirements. It’s common to overlook important aspects, leading to costly mistakes later on.

Selecting the perfect profile can feel overwhelming. However, taking time to explore options is crucial. Don’t rush this process. A thorough assessment will ultimately pay off in durability and performance. The right Aluminum Tube Profiles will enhance your project’s overall effectiveness.

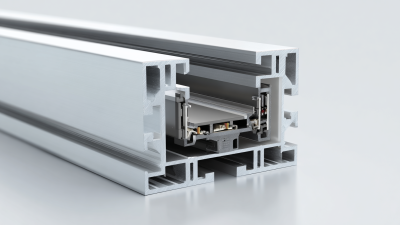

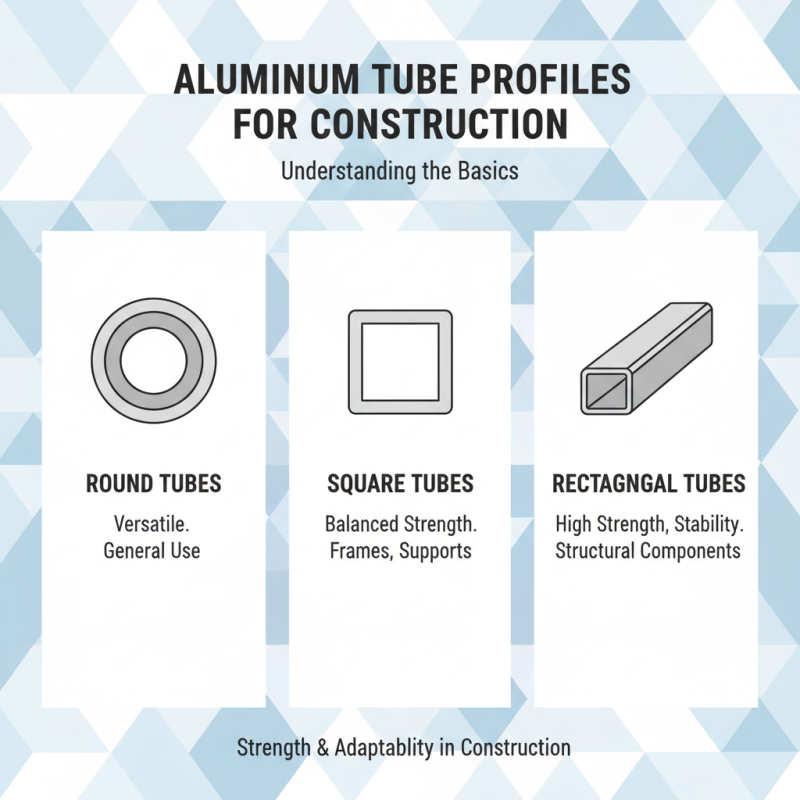

When selecting aluminum tube profiles for construction, understanding the basics is crucial. Aluminum tubes come in various shapes, such as round, square, and rectangular. Each shape serves different functions. For instance, rectangular tubes are often used for structural components due to their strength and stability.

According to a recent industry report, aluminum's lightweight nature can reduce construction costs by up to 30%. This aspect makes it a popular choice for many projects. However, it's essential to consider the specific requirements of your construction. Not all aluminum alloys are suitable for every application. Choosing the wrong profile can lead to structural weaknesses.

Moreover, it's vital to keep in mind the environmental impact. Aluminum is highly recyclable, which adds to its appeal. However, the production process consumes significant energy. It's a point worth reflecting on, especially in today’s construction landscape. Understanding the trade-offs ensures that your project is both efficient and sustainable.

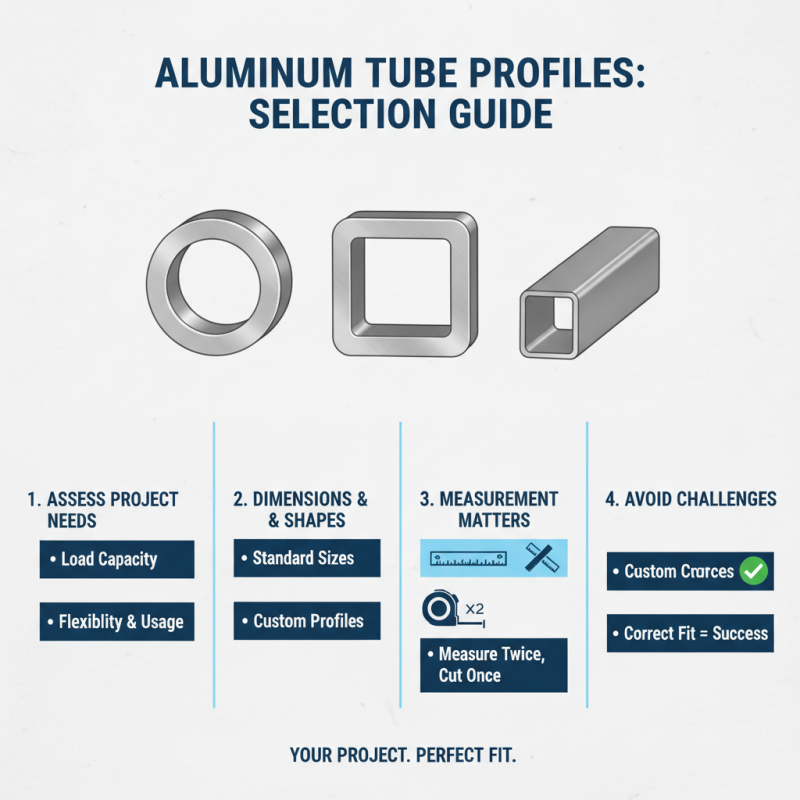

When selecting aluminum tube profiles, understanding the dimensions and shapes is crucial. Start by assessing the requirements of your project. Consider the load capacity, flexibility, and intended usage. Standard sizes are readily available, but custom dimensions may be required for a perfect fit. Measure twice, as an incorrect dimension can lead to unforeseen challenges.

Think about the shape of the profile. Round tubes offer strength and versatility, while square or rectangular profiles provide better structural integrity in certain applications. Assess the aesthetic appeal as well. Sometimes, the right shape not only delivers functionality but also enhances the visual aspect of your design.

It's easy to overlook details. You might think any dimension will work, but real-world applications often prove otherwise. Balancing structural needs with design aesthetics can be tricky. Reflect on past projects to identify what worked and what didn’t. This analysis will guide your choice of dimensions and shapes in future aluminum projects.

When choosing aluminum tube profiles for your project, understanding aluminum alloys is crucial. Different alloys offer varied properties. For instance, 6061 aluminum is popular for its good corrosion resistance and weldability. It's often used in structural applications. However, its strength may not be as high as other alloys.

On the other hand, 7075 aluminum is renowned for its strength. It’s often used in aerospace applications. This alloy provides high tensile strength but is less corrosion-resistant. If you’re working in a wet environment, this might be a concern. Consider the trade-offs between strength and corrosion resistance as you decide.

Remember to think about the specific needs of your project. Reflect on where the profiles will be used. Will they face extreme conditions? Or will they be indoors? Each scenario requires a different approach. Sometimes, it’s not just about strength, but how the material complements your project’s design. Evaluating these factors can lead to better decisions.

| Aluminum Alloy | Key Properties | Typical Applications | Strength (MPa) | Weight (g/m) |

|---|---|---|---|---|

| 6061 | Good corrosion resistance, weldable | Construction, automotive, marine | 290 | 270 |

| 6063 | Excellent extrusion characteristics | Architectural applications, window frames | 240 | 263 |

| 2024 | High strength, low corrosion resistance | Aerospace structures | 420 | 271 |

| 7075 | Very high strength, good fatigue resistance | Aircraft components, military applications | 570 | 281 |

| 5083 | Excellent corrosion resistance | Marine environments, pressure vessels | 330 | 275 |

When selecting aluminum tube profiles, cost-effectiveness and sustainability play essential roles. Aluminum is lightweight yet strong. According to the Aluminum Association, recycling aluminum uses 95% less energy than producing new aluminum. This significant energy saving highlights sustainability. Using recycled aluminum also reduces greenhouse gas emissions by up to 90%.

Cost considerations are critical in any project. The price of aluminum fluctuates based on market demand. Understanding these trends can help in budgeting. A 2021 report noted that aluminum prices surged by 30% due to increased global demand. This can affect project costs. Sticking to well-planned budgets while considering material sources is crucial.

Quality and availability of aluminum profiles matter too. Sometimes, lower-cost options can compromise quality. In a rush, the wrong choice can lead to greater expenses later. Assessing suppliers and their practices helps in making informed decisions. It’s a balance of immediate costs versus long-term sustainability.

When selecting aluminum tube profiles, compliance with industry standards is critical. Each project has specific requirements that must be met. Ensure the materials meet structural integrity ratings. Look for certifications from recognized organizations. This helps avoid potential issues down the line.

Consider local regulations as well. Different regions impose varying standards for aluminum use. Always verify that your chosen profiles are suitable for your location. This will prevent costly redesigns or penalties. Sometimes, less popular profiles might comply better with regulations. Be open to explore alternatives.

Documentation is another key element. Often, essential compliance papers are overlooked. Ensure all necessary reports are available before starting your project. A lack of paperwork can lead to delays. Attention to detail at this stage can save time and resources later on. Balancing aesthetics and regulations may not be easy. However, it’s a critical step in ensuring project success.