Aluminum profiles have become a cornerstone in various manufacturing sectors. According to a recent industry report by Research and Markets, the global aluminum extrusion market is projected to grow at a CAGR of 6.5% from 2021 to 2026. This growth highlights the increasing demand for aluminum profiles in automotive, construction, and consumer goods.

The versatility of aluminum profiles is undeniable. They are lightweight, corrosion-resistant, and easy to fabricate. This flexibility allows engineers to design innovative products. However, selecting the right aluminum profile can be challenging. There are multiple options available, each serving different needs and specifications. Quality matters, as using inferior profiles can compromise structural integrity.

Additionally, market trends indicate a shift toward sustainable materials. Aluminum is 100% recyclable, making it an eco-friendly choice. This aspect has encouraged many companies to switch to aluminum profiles. However, we must consider the environmental impact of mining bauxite. It’s crucial to reflect on the entire lifecycle of aluminum production. Understanding both the benefits and drawbacks can guide better decision-making for future projects.

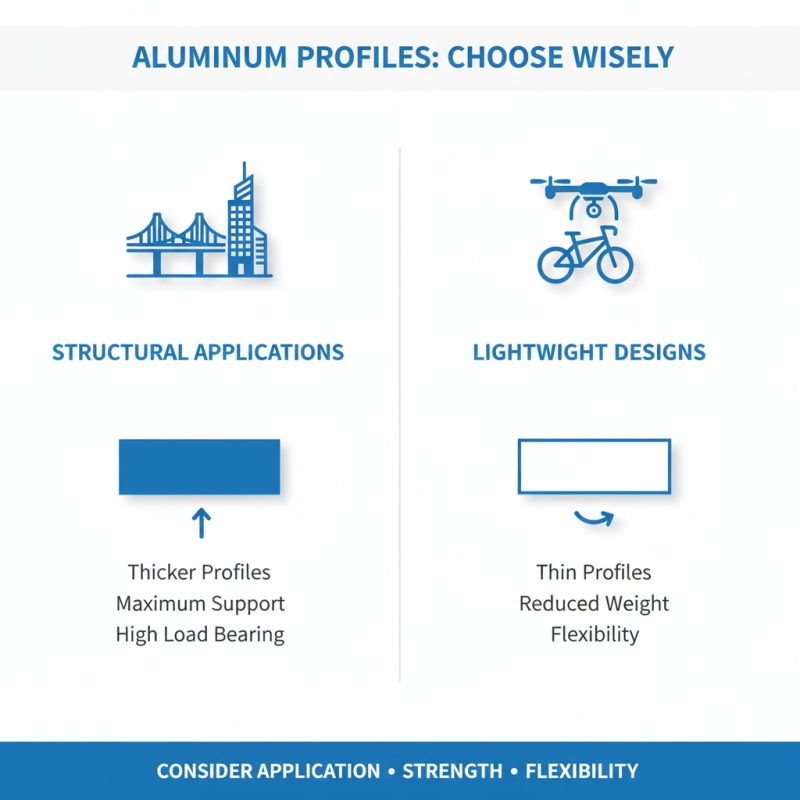

When choosing aluminum profiles for your project, consider the application carefully. Different projects require specific strengths and flexibilities. For structural applications, thicker profiles may provide the necessary support. For lightweight designs, thin profiles can reduce weight without compromising integrity.

Think about the finish of the aluminum. Anodized surfaces can enhance durability and aesthetics. Powder coating is also a popular choice for added color and protection. However, remember that the finish may affect cost and lead time. Sometimes, the extra time spent on finishing might not be viable for tight deadlines.

Reflect on the profile’s compatibility with other materials. Aluminum can bond well with various substances. However, in some cases, using dissimilar materials may lead to issues like corrosion. Always prioritize the long-term interaction of materials. You might uncover unexpected challenges during assembly or use, which can impact your project's success. Choose wisely and remain flexible in your approach.

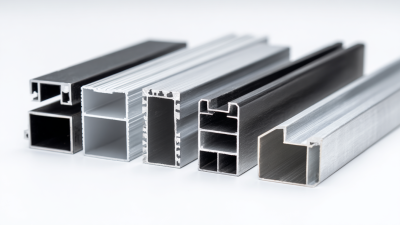

Aluminum profiles are essential in various industries. They provide strength and versatility. Different types are available, catering to various applications.

Extruded aluminum profiles are widely used. They come in various shapes and sizes. This type allows for easy customization. According to a report from Aluminum Association, the demand for extruded products has increased by 5% annually. This trend highlights their growing importance in construction and manufacturing.

Structural aluminum profiles offer durability and lightweight properties. Many industries use them for framework and supports. For instance, the aerospace sector utilizes aluminum due to its favorable strength-to-weight ratio. However, sourcing high-quality structural profiles can be challenging. Not every supplier meets stringent industry standards.

Machined aluminum profiles also play a crucial role. These profiles undergo precise cutting and shaping. They often fit specific project requirements. However, the machining process can be costly. It requires skilled labor and advanced technology. Some companies face challenges with cost management in this area.

When selecting aluminum profiles for your project, consider several key factors. The quality of aluminum used plays a crucial role. Pure aluminum is often lighter but less strong. Alloyed aluminum can provide higher strength and better durability. This choice can significantly alter your project outcomes.

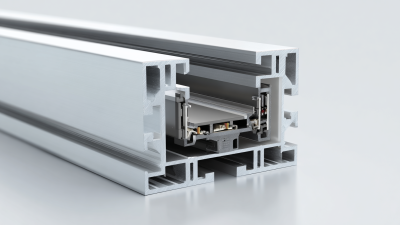

Next, the manufacturing process cannot be overlooked. Different methods can yield varying results in smoothness and precision. Some profiles may have minor imperfections that affect their functionality. Inspecting these details can prevent future issues. Additionally, the surface treatment of aluminum profiles impacts resistance to corrosion. A well-treated surface can extend its lifespan.

Finally, dimensions and tolerances matter greatly. Profiles that are slightly off can lead to alignment problems. This mistake could potentially compromise the entire structure. Ensuring accurate measurements may require additional checks. Ultimately, the pursuit of perfection in aluminum profiles is an ongoing challenge in any project.

Aluminum profiles find diverse applications across numerous industries, thanks to their unique properties. These profiles are lightweight yet strong, making them ideal for manufacturing frames, supports, and fixtures. In the construction industry, aluminum profiles are widely used in window frames and structural components. Their resistance to corrosion ensures durability even in harsh conditions.

In the automotive sector, aluminum profiles help reduce vehicle weight, improving fuel efficiency. These profiles can be seen in body structures, heat exchangers, and more. However, some manufacturers face challenges in balancing strength and weight. The right choice of aluminum alloy is crucial, and missteps can lead to structural failures.

Packaging is yet another area where aluminum profiles shine. They are widely employed to design protective casings for electronic goods and machinery. Despite their advantages, the recycling process can be complicated. Not all profiles are easily recyclable, which raises sustainability concerns. Such issues highlight the need for continuous improvement in production processes.

When working with aluminum profiles, a solid understanding of their characteristics is crucial. Aluminum's lightweight nature makes it a favorite in construction. According to a recent industry report, aluminum can be 85% lighter than steel, which contributes to reduced transportation costs. However, its strength-to-weight ratio must be considered. This balance is essential for reliable structural integrity.

**Tip:** Always check the quality of the aluminum. Look for profiles that meet industry standards. This ensures durability and safety. Improper selections can lead to excessive bending or warping.

Another common challenge is the thermal expansion of aluminum. Aluminum expands when heated. This can cause issues in joint connections during fluctuating temperatures. Professionals recommend planning for expansion gaps in your designs.

**Tip:** Use thermal breaks in areas prone to heat. This will minimize expansion-related complications. Remember, a well-planned project incorporates these details to avoid future problems. Awareness of these factors can reflect positively on project outcomes.

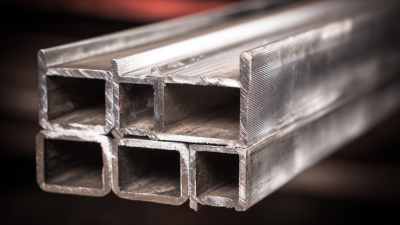

| Profile Type | Dimensions (mm) | Weight (kg/m) | Common Uses | Advantages |

|---|---|---|---|---|

| Square Tube | 20 x 20 | 0.89 | Frameworks, Railing | High Strength, Versatile |

| Rectangular Tube | 30 x 20 | 1.47 | Furniture, Structural | Stylish, Durable |

| Angle Profile | 25 x 25 | 1.16 | Bracing, Framing | Corrosion Resistant |

| Channel Profile | 40 x 20 | 1.92 | Support Structures | Lightweight, Versatile |

| Flat Bar | 100 x 10 | 0.92 | Brace, Support | Easy to Machine |