In the rapidly evolving construction and manufacturing sectors, the choice of materials plays a pivotal role in project success. Among the various options available, Aluminum Profiles stand out as an exceptional choice due to their unique properties and wide-ranging applications. According to a report by the International Aluminum Association, the global aluminum market is expected to grow to over 60 million tons by 2025, driven by the material's lightweight, corrosion-resistant, and recyclable characteristics. This trend underscores the increasing reliance on Aluminum Profiles in various industries, from architecture to automotive.

The versatility of Aluminum Profiles is further demonstrated by their ability to be customized for specific project requirements, enhancing both aesthetics and functionality. Research highlights that projects utilizing Aluminum Profiles can achieve up to 20% better energy efficiency compared to traditional materials, thanks to aluminum's excellent thermal management properties. As industries seek both sustainability and efficiency, incorporating Aluminum Profiles into future projects emerges as a strategic decision that not only meets modern standards but also contributes to long-term economic benefits.

Aluminum profiles are rapidly gaining popularity in modern construction projects due to their unique advantages. One of the standout benefits is their exceptional corrosion resistance, particularly when advancements in corrosion protection for recycled aluminum are taken into account. While secondary aluminum has faced challenges in this area, continuous improvements are enhancing its durability, making it a preferred choice for various applications, including metal roofing. As the metal roofing market is projected to reach USD 32.19 billion by 2031, the use of aluminum profiles is expected to rise significantly due to their lightweight nature, which reduces structural loads and makes construction faster and more efficient.

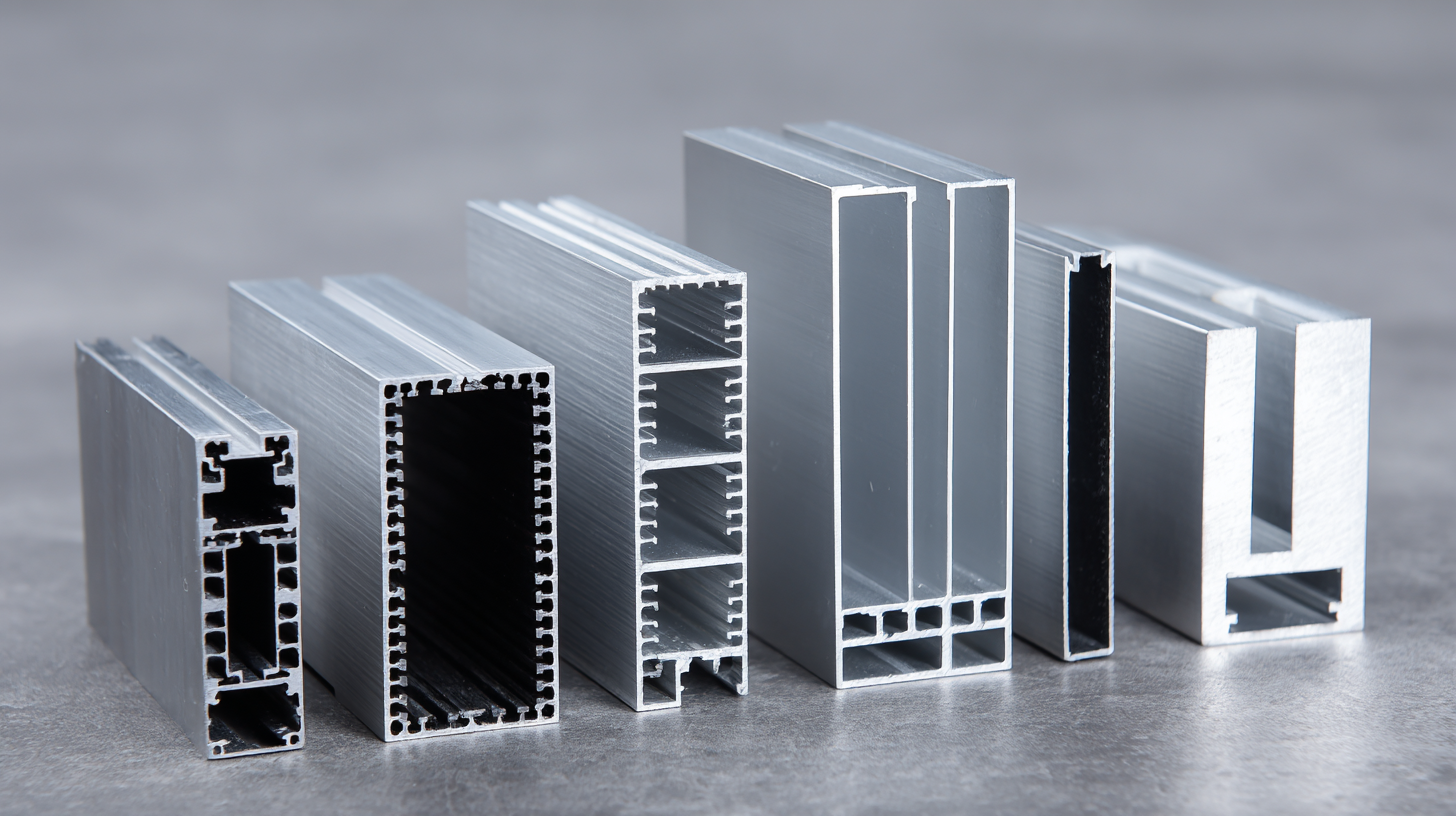

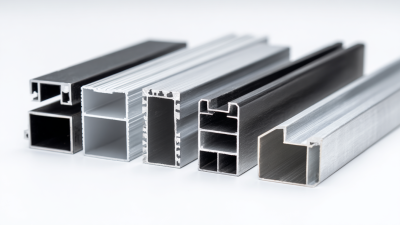

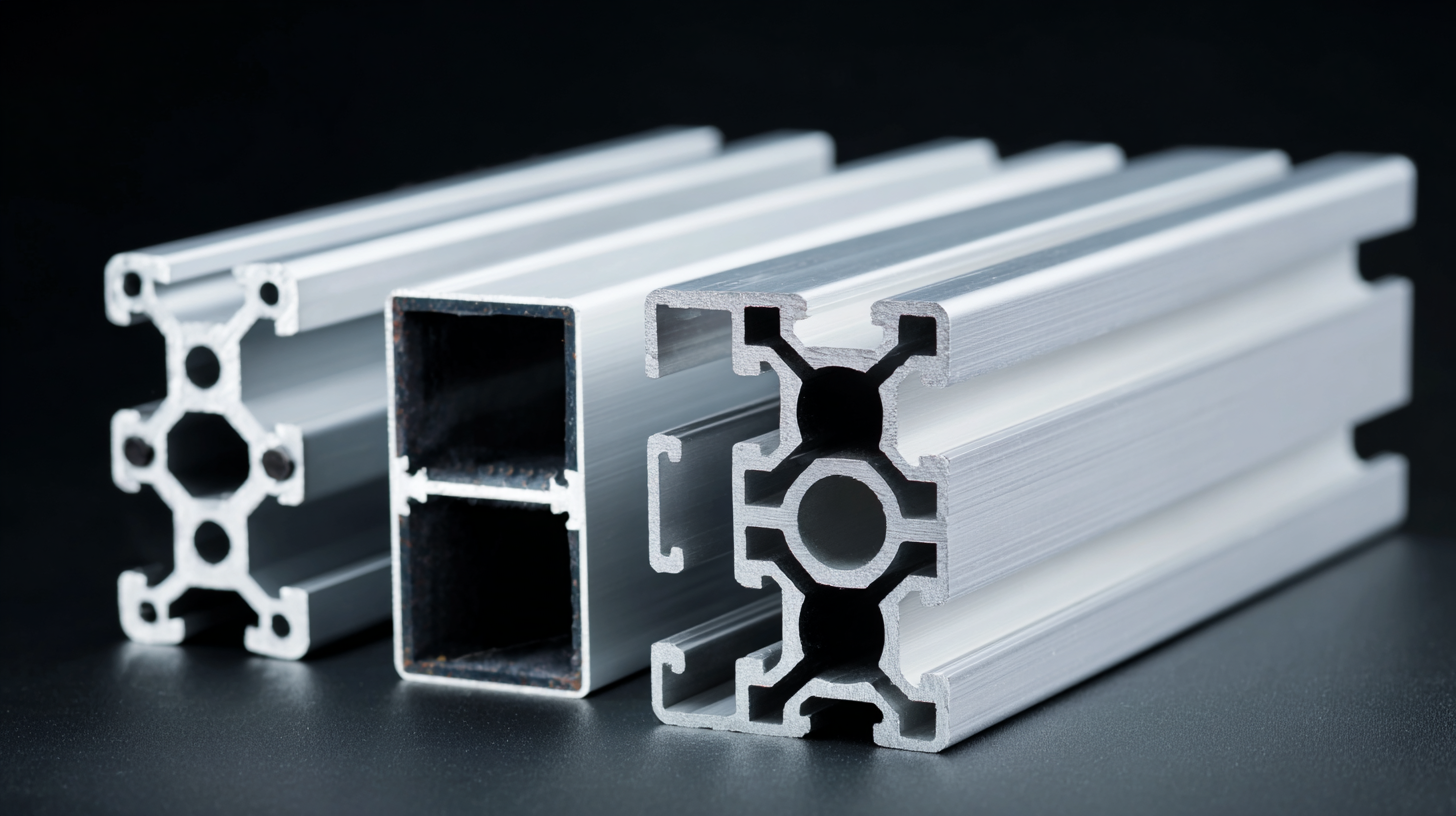

In addition to their durability, aluminum extrusions are revolutionizing building design with their versatility. These materials can be easily shaped and customized, catering to a wide range of architectural needs. The growing trend towards aluminum bridges highlights this strength, as they not only require less maintenance but can also be assembled more quickly compared to traditional materials. This innovation contributes to better project timelines and overall project efficiency in the industry.

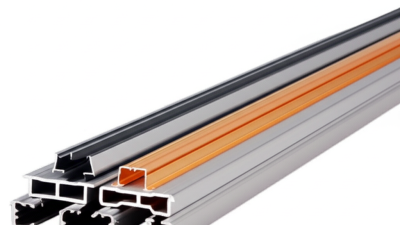

Tips for utilizing aluminum profiles effectively in your next project include considering the specific environmental conditions your structure will face and investing in high-quality aluminum for enhanced longevity. Additionally, exploring different aluminum extrusion designs can provide creative solutions that blend aesthetics with functionality, ensuring your project stands out while remaining robust and efficient.

| Benefit | Description |

|---|---|

| Lightweight | Aluminum profiles are significantly lighter than steel or wood, making them easier to transport and install. |

| Corrosion Resistance | Aluminum naturally forms a protective oxide layer, which prevents rust and corrosion. |

| Recyclability | Aluminum is 100% recyclable without loss of quality, promoting sustainability in construction. |

| Strength-to-Weight Ratio | Aluminum has a high strength-to-weight ratio, providing structural integrity without excessive weight. |

| Versatility | Available in various shapes and sizes, aluminum profiles can be adapted to meet specific design requirements. |

| Aesthetic Appeal | Aluminum can be finished in multiple colors and textures, enhancing the visual appeal of modern architecture. |

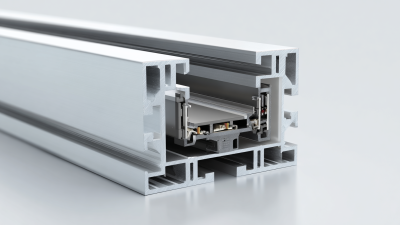

| Thermal Conductivity | Aluminum profiles conduct heat effectively, which can be advantageous in energy-efficient building designs. |

| Cost-Effectiveness | While initially more expensive than some materials, the long-term savings from durability and maintenance make aluminum a cost-effective choice. |

| Easy to Fabricate | Aluminum can be easily machined, welded, and extruded, allowing for quick modification and assembly during construction. |

Aluminum profiles have emerged as a popular choice for various projects due to their cost-effectiveness. When budgeting for materials, utilizing aluminum profiles can significantly reduce overall expenses without compromising quality. The lightweight nature of aluminum not only lowers transportation costs but also simplifies handling, making it easier for construction teams to complete projects efficiently. This means that savings are realized from the onset, as less time and effort are spent on logistics.

Tips for maximizing cost savings include selecting local suppliers for aluminum profiles to minimize shipping costs and opting for standard sizes to avoid custom fabrication expenses. Additionally, consider investing in high-quality aluminum, which may have a higher upfront cost but offers better durability and lower maintenance needs over time. This will save money in the long run, as it reduces the frequency of replacements or repairs.

Another tip for enhancing cost-effectiveness is to fully utilize the flexibility of aluminum profiles in design. By incorporating modular systems, you can adapt and reconfigure components for future projects easily, ultimately prolonging their lifecycle and further driving down costs. Leveraging the full potential of aluminum can lead to exemplary results while keeping your budget intact.

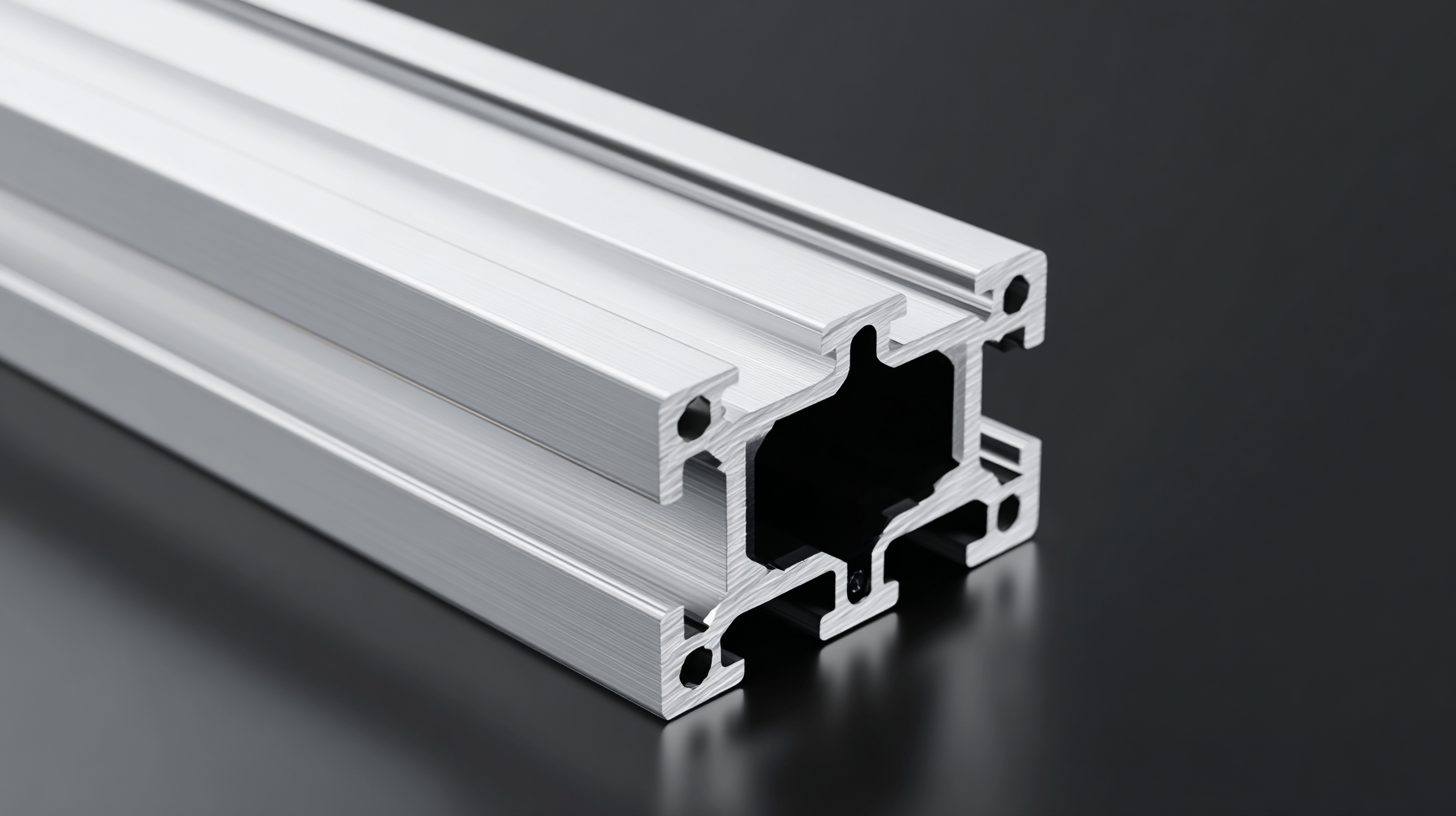

Aluminum profiles combine remarkable durability with a lightweight design, making them an ideal choice for a variety of projects. Their inherent strength allows structures to withstand environmental stressors without the material compromising integrity. This durability extends the lifespan of products, reducing maintenance costs and the frequency of replacements. Whether used in the construction of frames, furniture, or industrial applications, aluminum profiles provide a robust solution that can handle demanding conditions.

In addition to their strength, aluminum profiles are incredibly lightweight, which simplifies handling and installation processes. This makes them especially advantageous for projects where weight is a critical factor, such as in transportation and aerospace industries. The lightweight nature does not mean sacrificing quality; instead, it facilitates innovative design possibilities. Designers can create intricate shapes and structures without overwhelming concerns about weight, opening up new avenues for creativity and functionality in their projects.

Aluminum profiles have gained immense popularity in various industries due to their exceptional versatility and adaptability. They can be tailored to meet the specific requirements of a wide range of projects, from architectural structures to intricate machinery components. This flexibility allows designers and engineers to innovate and create solutions that are not only functional but also aesthetically pleasing. Whether you're utilizing aluminum for framing, shelving, or custom enclosures, the adaptability of these profiles is unmatched.

When selecting aluminum profiles for your project, consider the specific application and environment. For example, if you're working on outdoor designs, opt for anodized aluminum finishes for enhanced durability and corrosion resistance. Additionally, contemplate modular designs that allow for easy adjustments and expansions in the future. With the right design approach and selection, aluminum profiles can be utilized across numerous applications while maintaining structural integrity.

Tip: Always evaluate the load-bearing capacity of aluminum profiles when planning your project to ensure safety and performance. Furthermore, remember that proper cutting and joining techniques can significantly enhance the longevity and stability of your aluminum structures. By keeping these considerations in mind, you can effectively leverage the versatility of aluminum profiles to meet diverse project needs.

The eco-friendly benefits of using aluminum profiles in construction and manufacturing are increasingly recognized, particularly as industries strive for sustainability and lower emissions. With aluminum being infinitely recyclable, its closed-loop recycling capabilities mean that it can be repurposed without losing quality, significantly reducing the environmental impact associated with new aluminum production. According to recent studies, recycling aluminum saves up to 95% of the energy required to produce new aluminum from raw materials. This makes recycling not only an environmentally responsible choice but also a cost-effective one.

Furthermore, the push for "green aluminum" is transforming the metal industry, as manufacturers seek to reduce their carbon footprints. Low-carbon aluminum is often integrated into supply chains aiming for more sustainable processes, with innovations such as continuous filtration of polluted aluminum alloys leading to more efficient recycling operations. Industry reports indicate that by prioritizing eco-friendly practices, companies can enhance their sustainability profiles while meeting the rising consumer demand for environmentally conscious products. As we enter a new era of manufacturing, the role of aluminum in supporting these initiatives cannot be overstated, marking it as a pivotal material for the future.