In the world of construction and design, the choice of materials can significantly impact the success of a project. Among the myriad options available, Aluminum Profiles stand out due to their versatility, strength, and lightweight properties. As noted by industry expert John Harrington, "The durability and adaptability of aluminum profiles make them an essential component in modern architecture and manufacturing." This statement encapsulates the growing trend towards using aluminum profiles in various applications, from residential buildings to industrial facilities.

As we delve into the "2025 Ultimate Guide to Choosing Aluminum Profiles for Your Projects," we will explore the critical factors to consider when selecting the right aluminum profiles. From understanding the different types available to assessing their structural integrity and aesthetic appeal, our guide aims to provide comprehensive insights for architects, engineers, and DIY enthusiasts alike. By honing in on these aspects, project leaders can ensure that their choice of Aluminum Profiles not only meets operational requirements but also enhances the overall design and functionality of their projects.

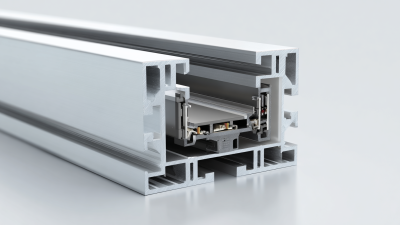

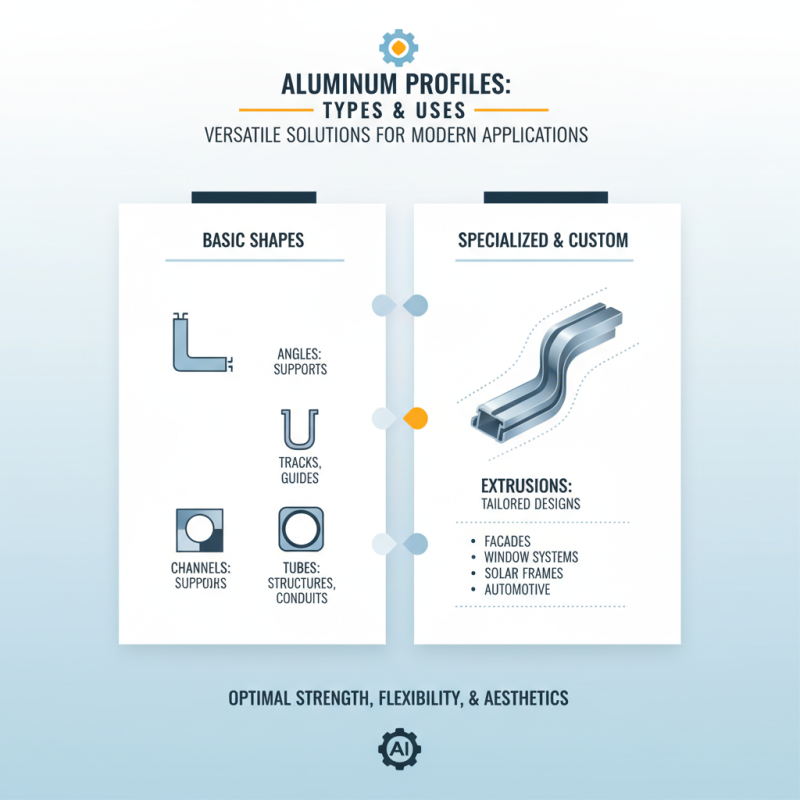

Aluminum profiles come in a variety of types, each tailored for specific applications, making them a popular choice in construction, manufacturing, and design projects. Basic categories of aluminum profiles include standard shapes like angles, channels, and tubes, as well as more specialized varieties such as extrusions that can be custom-designed to meet unique structural requirements. Understanding these different types is crucial for selecting the right profile that provides optimal strength, flexibility, and aesthetic appeal.

Applications of aluminum profiles span numerous industries. In construction, they are often used for window frames, door frames, and structural supports due to their lightweight yet durable nature. In the manufacturing sector, aluminum profiles serve as the backbone for assembly line equipment, machine structures, and protective enclosures. Moreover, in the realm of design, they are favored for creating modern furniture, fixtures, and decorative elements, allowing for both functional and artistic expression. Knowing the specific characteristics and applications of different aluminum profiles ensures that you can make informed choices that elevate your project’s success.

When selecting aluminum profiles for your projects, it is essential to consider several key factors that ensure optimal performance and compatibility with your specific requirements. One primary consideration is the alloy composition, as different aluminum alloys offer varying strengths, corrosion resistance, and weldability. According to a recent industry report by the Aluminum Association, aluminum alloys 6061 and 6063 are among the most popular for architectural applications due to their excellent mechanical properties and finishability. Understanding the mechanical properties of these alloys can help you choose the right profile for structural or aesthetic applications.

Another critical aspect to evaluate is the profile's intended application. Whether for construction, transportation, or electronics, aluminum profiles vary greatly in design and functionality. For instance, an analysis from the International Aluminum Institute reveals that customized profiles can improve material efficiency and reduce waste by up to 30% in manufacturing processes. This highlights the need to assess your project's specific requirements, including load-bearing capacity, thermal conductivity, and durability against environmental factors. Ensuring that your chosen aluminum profile meets these criteria will lead to a more successful and sustainable project outcome.

| Profile Type | Common Applications | Key Features | Standard Lengths | Weight per Meter |

|---|---|---|---|---|

| Standard Extrusion | Frames, Supports | Versatile, Lightweight | 2m, 3m, 6m | 0.75 kg/m |

| T-Slot Profile | Workstations, Fixtures | Modular Design, Easy Assembly | 1m, 2m, 3m | 1.2 kg/m |

| Square Tube | Structural Frames, Railing | High Strength, Sturdy | 2m, 4m | 2.5 kg/m |

| Angle Profile | Brackets, Reinforcement | L-Shaped, Supportive | 1m, 2m | 1.0 kg/m |

| Round Tube | Pipes, Fittings | Corrosion Resistant, Smooth | 3m, 6m | 1.8 kg/m |

When choosing aluminum profiles for your projects, understanding the properties of different aluminum alloys is crucial. Aluminum alloys are typically categorized based on their strength, weight, and cost, which can significantly impact the performance and budget of your project. The two broad categories of aluminum alloys are wrought alloys and cast alloys. Wrought alloys are known for their superior strength-to-weight ratio, making them ideal for structural applications. Conversely, cast alloys often excel in situations where complex shapes are required and can be more economical for large parts.

Tips: Always consider the specific requirements of your project. For example, if weight savings are critical, opt for high-strength alloys, such as 7075 or 6061, which provide excellent durability without the added heft. On the other hand, if your project is more budget-sensitive, selecting 3003 or 5052 alloys might offer a more cost-effective solution while still delivering adequate performance.

Cost considerations should not be overlooked when selecting aluminum profiles. The initial expense of higher-grade alloys can be offset by their performance efficiency and longevity, reducing maintenance and replacement costs in the long run. It's essential to evaluate the lifecycle of the material in relation to your project's requirements.

Tips: Conduct a cost-benefit analysis comparing different alloys based on your specific application. Also, consult industry standards and guidelines to ensure compliance with safety and performance benchmarks.

Designing with aluminum profiles involves more than just selecting the right materials; it requires a keen understanding of performance and functionality. Aluminum profiles are known for their lightweight nature, versatility, and resistance to corrosion, which makes them an ideal choice for various projects ranging from construction to home décor. To optimize their performance, it's crucial to consider factors like the profile's shape, thickness, and finish, which can significantly impact the strength and aesthetic appeal of your design.

When selecting aluminum profiles, one essential tip is to analyze the load-bearing requirements of your project. Make sure to choose a profile that can adequately support the intended weight and stress it will encounter during its use. Additionally, consider the environmental conditions where the profiles will be installed. Profiles exposed to harsh weather may need a specific finish or coating to enhance durability.

Another important aspect is the joining methods you plan to use. Aluminum profiles can be connected using various techniques such as welding, screwing, or using connectors. Each method has its own advantages, so selecting the right one based on your design’s complexity and the strength requirements is vital. Always remember to account for thermal expansion and contraction, especially in larger projects, to ensure your design maintains performance over time.

Aluminum profiles are increasingly recognized for their environmental benefits, particularly in terms of sustainability and recycling. As a lightweight and durable material, aluminum significantly reduces energy consumption during transportation and installation, contributing to a lower carbon footprint. Furthermore, the energy required to recycle aluminum is substantially less than that needed for its production from raw materials. This makes aluminum profiles a smart choice for environmentally conscious projects, offering both functional advantages and a positive impact on the planet.

The recycling process for aluminum is highly efficient, allowing nearly 100% of the material to be reused without degradation of its properties. This infinite recyclability not only conserves natural resources but also minimizes waste in landfills. Projects utilizing aluminum profiles can leverage this loop of sustainability to enhance their green credentials, appealing to eco-aware consumers and stakeholders. By choosing aluminum, designers and builders can contribute to a circular economy, foster resource efficiency, and support a healthier environment for future generations.