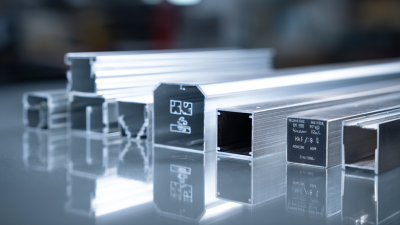

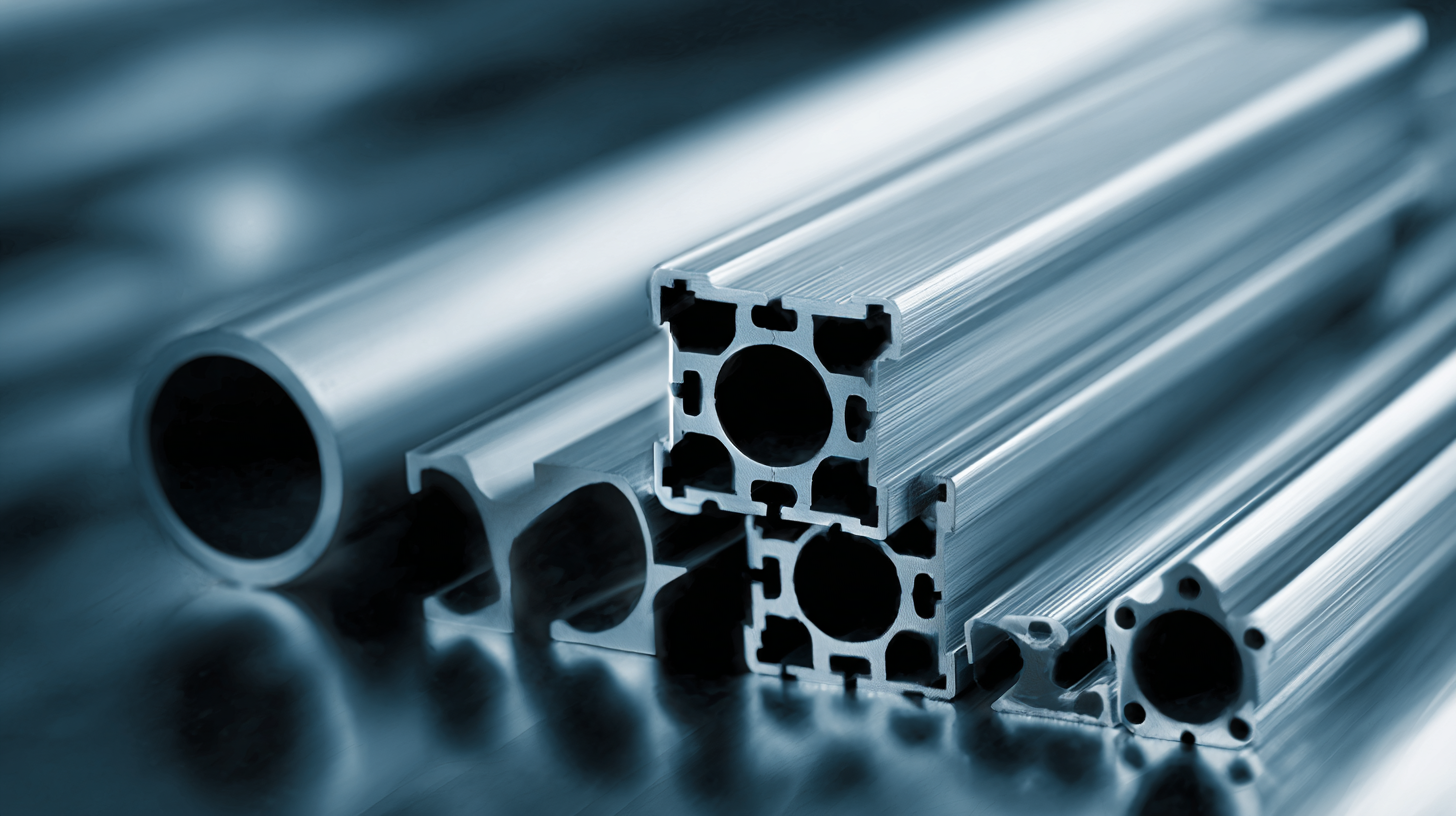

In today's fast-paced industrial landscape, the significance of Anodized Aluminum Profiles cannot be overstated. These versatile components offer a unique combination of durability, aesthetic appeal, and resistance to corrosion, making them ideal for a wide range of applications. Whether in construction, transportation, or consumer goods, understanding the intricacies of anodized aluminum and its profiles is essential for architects, engineers, and designers alike. This guide will delve into the fundamentals of anodized aluminum profiles, showcasing their various types, benefits, and practical applications. Additionally, we will provide valuable tips for selecting the right profiles for your specific needs, ensuring that you make informed decisions that enhance both functionality and design. Join us as we explore the ultimate details that make anodized aluminum profiles a critical choice in modern manufacturing and design.

Anodization is a crucial electrochemical process that enhances the surface properties of aluminum, resulting in a durable and corrosion-resistant material. This process not only thickens the natural oxide layer on aluminum but also allows for the incorporation of various beneficial properties, such as increased resistance to wear and improved aesthetic qualities through color anodization. Recent advancements in anodizing technology have highlighted its potential applications in various industries, including construction, automotive, and electronics. For instance, innovative anodizing techniques have been employed to produce antibacterial surfaces, showcasing the adaptability of anodized aluminum in addressing modern health-related concerns.

Additionally, the Anodic Aluminum Oxide (AAO) market is poised for significant growth, with forecasts indicating an increase from USD 1.2 billion in 2024 to USD 2.5 billion by 2033. The demand for high-performance anodized products is being driven by advancements in electrochemical treatment methods that enhance surface performance. Research on alternative electrolytes and current density regimes is aiding in the development of superior anodized finishes, enriching the material's applicability in high-tech sectors, such as engineering and renewable energy solutions. As industries continue to explore sustainable options and improve product longevity, anodized aluminum's role becomes increasingly vital in meeting these challenges.

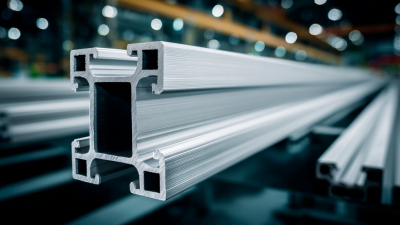

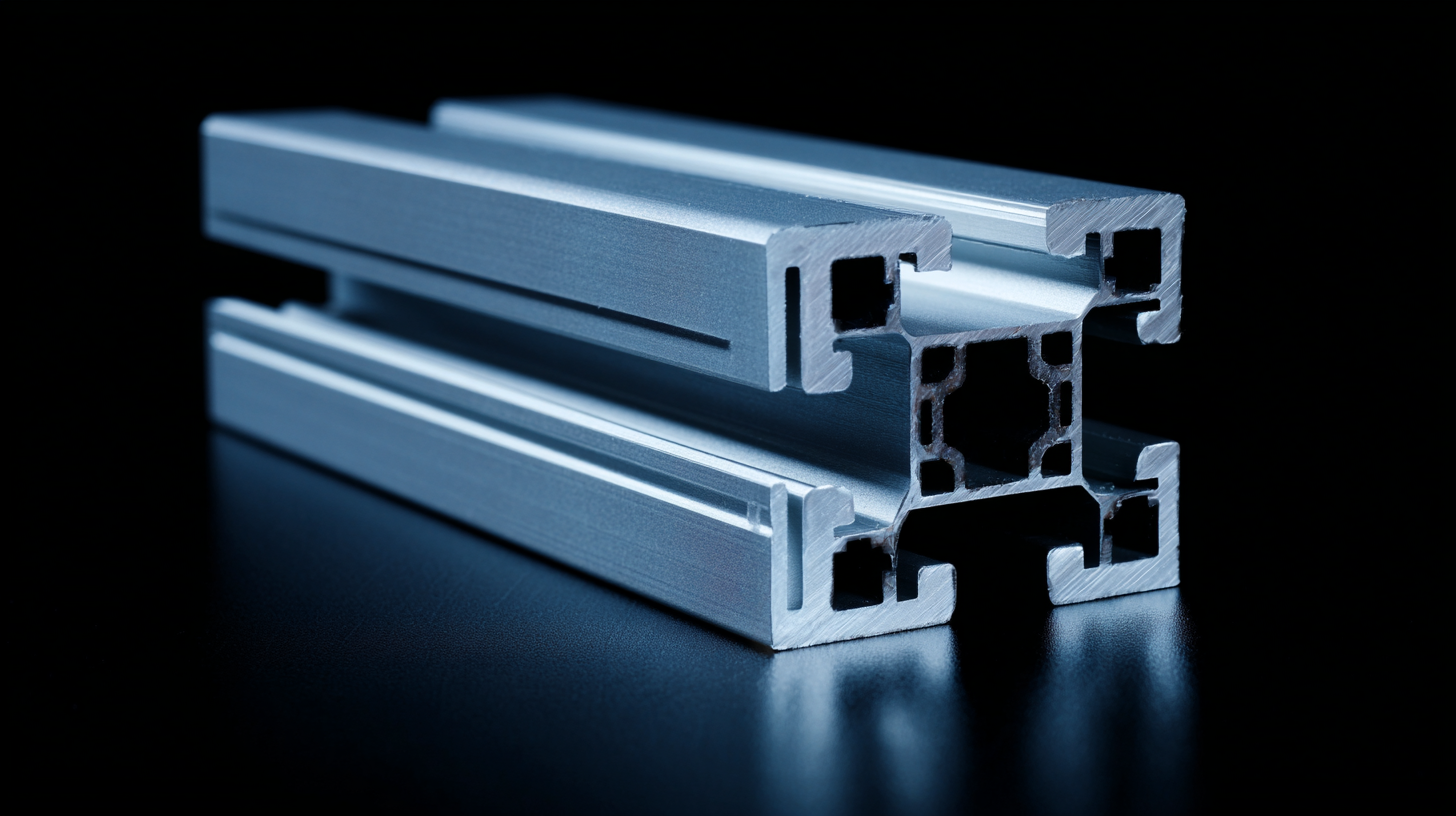

Anodized aluminum is a modified version of regular aluminum, enhanced through an electrochemical process that creates a protective oxide layer on its surface. This anodization process significantly improves the durability and corrosion resistance of the aluminum, making it ideal for demanding environments. Unlike regular aluminum, which can be prone to oxidation and wear over time, anodized aluminum is less susceptible to scratches and damage, offering a longer lifespan for products and components.

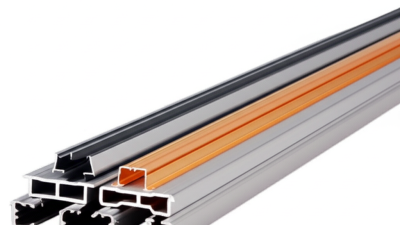

Another key characteristic that distinguishes anodized aluminum from regular aluminum is its enhanced aesthetic appeal. The anodization process allows for a range of colors and finishes, which can be integrated into the product without compromising the integrity of the material. This versatility makes anodized aluminum a popular choice in various industries, including architecture, automotive, and consumer electronics. The ability to combine functionality with style sets anodized aluminum apart, catering to both practical and design-oriented applications.

Anodized aluminum profiles have emerged as key components across various industry sectors due to their unique properties and versatility. As the global aluminum profiles and accessories market is projected to grow from USD 56.35 billion in 2024 at a CAGR of 8.1% between 2025 and 2030, the adaptability of anodized profiles in construction, automotive, and electronics is increasingly recognized. Their enhanced corrosion resistance and aesthetic appeal make them ideal for architectural applications, such as facades and window frames, while maintaining structural integrity in demanding environments.

The aluminum alloy extrusions market is also witnessing significant expansion, forecasted to grow from USD 80 billion in 2024. This growth is driven by the innovative applications of aluminum extrusions in modern construction, where they revolutionize design and functionality. For instance, the ability to create complex shapes enables architects to explore new structural possibilities. Moreover, the increasing emphasis on lightweight materials in the automotive industry further amplifies the necessity for high-performance aluminum profiles that contribute to energy efficiency and reduced emissions. As these trends continue, anodized aluminum profiles will play a pivotal role in building and construction, demonstrating their essential place in future industry developments.

When it comes to selecting a finishing method for aluminum profiles, anodizing stands out for its unique advantages over other coatings and finishes. According to a recent report by the Aluminum Association, the global anodized aluminum market is projected to reach $8 billion by 2026, driven by increased demand in construction and automotive applications. Anodized aluminum provides a durable, corrosion-resistant surface without the need for bulky paint layers, resulting in a lighter overall product. In contrast, powder coating, while also popular, can add significant weight and may not offer the same level of scratch resistance as anodized surfaces.

Moreover, a comparative analysis reveals that anodized aluminum can withstand harsher environmental conditions than conventional coatings. A study from the Journal of Materials Science indicated that anodized finishes exhibit up to 30% better performance in salt spray tests compared to standard powder-coated finishes. This exceptional resilience makes anodized aluminum a preferred choice in coastal areas or anywhere exposure to moisture could lead to deterioration. Overall, while both options have their merits, anodizing offers a combination of aesthetic appeal and robustness that suits a wide range of industrial applications.

Anodized aluminum profiles are renowned for their durability and aesthetic appeal, but proper maintenance and care are essential to ensure their longevity. To keep anodized surfaces looking pristine, it's crucial to implement effective cleaning routines. Regularly dusting with a soft cloth can prevent abrasive particles from scratching the surface. When deeper cleaning is needed, use mild detergents and warm water, avoiding harsh chemicals that may compromise the anodized layer.

Tips for maintaining anodized aluminum include applying a protective wax periodically to enhance shine and provide an additional layer of defense against environmental factors. Additionally, during the winter months, it's wise to remove snow or ice buildup gently to prevent damage. For outdoor installations, consider regularly checking for any signs of corrosion or discoloration; early intervention can save time and costly repairs later on. By following these best practices, users can maximize the lifespan and appearance of their anodized aluminum products.

| Property | Description | Best Practices | Common Applications |

|---|---|---|---|

| Corrosion Resistance | Anodized aluminum is significantly more resistant to corrosion compared to untreated aluminum. | Keep the surface clean; avoid abrasive materials. | Construction, marine applications. |

| Color Variety | Anodizing allows for a wide range of colors without the use of paints. | Use suitable dyes and ensure even application. | Architectural elements, automotive parts. |

| Durability | Anodized layers provide a hard surface that resists scratches and wear. | Regular inspections and gentle cleaning with non-abrasive solutions. | Consumer electronics, furniture. |

| Environmental Resistance | Resistant to UV light and weathering. | Use in outdoor settings and regular cleaning to maintain appearance. | Outdoor furniture, signage. |

| Weight | Lightweight material suitable for various applications without adding excessive weight. | Design products with optimal weight distribution. | Aerospace components, lightweight structures. |