In recent years, the demand for Aluminum Extrusion Tube Profiles has surged, driven by their versatility and lightweight properties, making them an essential component in various industries such as automotive, aerospace, and construction. According to a report by Grand View Research, the global aluminum extrusion market is expected to reach USD 67.3 billion by 2027, expanding at a CAGR of 4.8%. This growth underscores the increasing reliance on aluminum’s mechanical properties and sustainability, as it is 100% recyclable. Understanding the intricacies of aluminum extrusion tube profiles is crucial for engineers and designers striving to optimize their projects, whether for structural applications or intricate machinery components. This guide aims to provide a comprehensive overview of aluminum extrusion tube profiles, their manufacturing processes, applications, and tips for selecting the right profiles for your specific project needs.

Aluminum extrusion is a widely used manufacturing process that transforms aluminum alloy into desired shapes, enabling its application in various industries. Understanding the basics of aluminum extrusion tube profiles begins with recognizing the benefits of this process, such as lightweight design, strength, and corrosion resistance. According to a report from the Aluminum Association, the global aluminum extrusion industry was valued at approximately $40 billion in 2021, demonstrating its critical role in sectors like construction, automotive, and aerospace.

The versatility of aluminum tube profiles allows for customization that meets specific project needs. Profiles can be designed for standard applications, or tailored to unique requirements, enhancing performance and efficiency. According to a market research study by Freedonia Group, the demand for aluminum extrusions is projected to rise by 5.5% annually, driven by the increasing use of lightweight materials to improve fuel efficiency in vehicles and reduce greenhouse gas emissions. This highlights the growing importance of understanding aluminum extrusion tube profiles in making informed decisions for future projects, ensuring both functionality and sustainability.

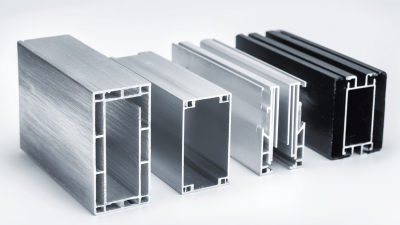

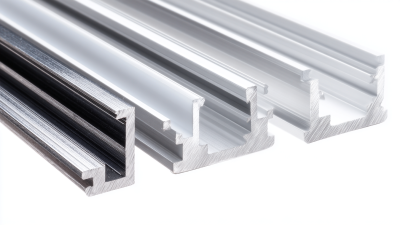

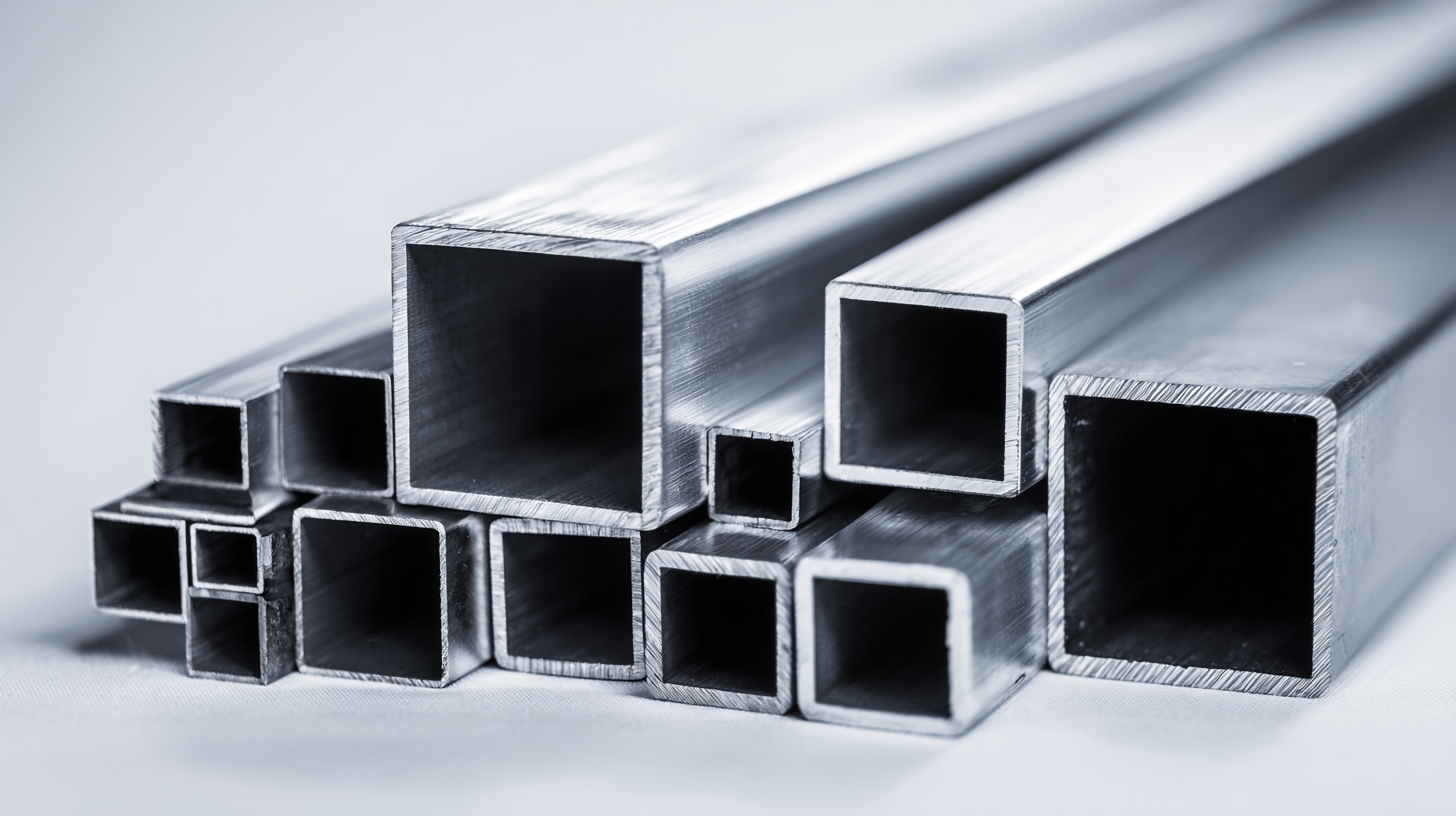

Aluminum extrusion tube profiles come in various shapes and sizes, each tailored to meet specific engineering and design requirements. The versatility of aluminum allows for an array of profiles such as round, square, and rectangular tubes, which can be adapted for structural, aesthetic, or functional purposes. According to the Aluminum Association, the global demand for aluminum extrusions is projected to grow by approximately 5.5% annually, indicating a rising interest in this lightweight yet durable material.

Round tubes, often employed in applications requiring fluid transfer or structural support, provide excellent strength-to-weight ratios. On the other hand, square and rectangular profiles are widely used in frames, furniture, and architectural applications due to their stability and ease of assembly. A report by Freedonia Group highlights that the architectural and transportation sectors are among the largest consumers of aluminum extrusions, underscoring the need for custom profiles tailored to project specifications. Understanding these distinctions can greatly enhance project outcomes and material efficiency.

When selecting aluminum extrusion tube profiles for projects, several key factors must be considered to ensure optimal performance and suitability. The type of application is paramount: whether for structural support, heat dissipation in cooling systems, or aesthetic design can significantly influence the choice of profile. For instance, cold plate anodized aluminum tubes not only provide effective thermal management for electronics but also enhance durability through surface treatment, making them ideal for laptop cooling systems.

Another crucial aspect to consider is the mechanical properties of the aluminum alloy used. Different alloys exhibit varying levels of strength, flexibility, and resistance to corrosion. For instance, the 6061 alloy is renowned for its excellent mechanical properties and is commonly used in manufacturing bicycle frames, demonstrating that aluminum can be a viable alternative to traditional materials like carbon or steel.

Tip: Always assess the weight-to-strength ratio of the profiles in regards to your project's specific needs. Some profiles may offer a lightweight advantage without compromising structural integrity. Also, consulting technical data sheets can provide insights into the performance characteristics of specific aluminum profiles, aiding in informed decision-making.

Aluminum extrusion tube profiles are increasingly becoming a vital component across various industries due to their versatility and strength. These profiles are utilized in construction, automotive, electronics, and even aerospace applications, providing lightweight yet durable solutions for structural needs. In the construction industry, for example, they are commonly used in window frames, curtain walls, and roofing systems, enabling both aesthetic appeal and functionality.

When working with aluminum extrusion tube profiles, it's crucial to consider their compatibility with specific applications. For instance, in the automotive sector, these profiles are preferred for manufacturing frames and support structures because of their excellent corrosion resistance and ability to withstand varying environmental conditions. Additionally, in the electronics industry, they serve as robust housings for delicate components, ensuring both protection and thermal management.

**Tip:** Always assess the specific requirements of your project, such as load specifications and environmental factors, before selecting an aluminum extrusion profile. This will help to avoid any compromises on safety or performance. **Tip:** Collaborating with experienced suppliers can provide insights on the latest profile designs and techniques, ensuring you optimize your project for efficiency and effectiveness. Remember, the right aluminum extrusion tube profile can significantly enhance the functionality and longevity of your projects.

| Profile Type | Dimensions (mm) | Application | Industry |

|---|---|---|---|

| Round Tube | 25 x 3 | Structural Frameworks | Construction |

| Square Tube | 30 x 30 x 2 | Furniture Manufacturing | Furniture |

| Rectangular Tube | 40 x 20 x 3 | Automotive Parts | Automotive |

| L Shape Profile | 20 x 20 x 2 | Support Structures | Manufacturing |

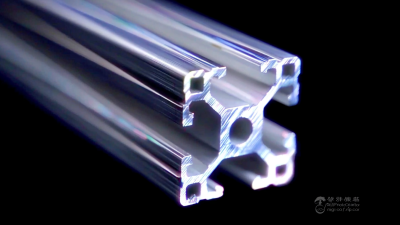

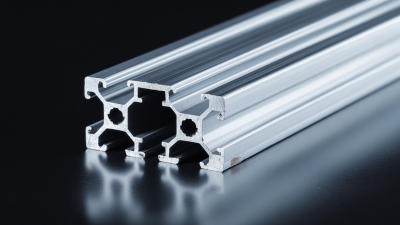

| T Slot Profile | 40 x 40 | Modular Frameworks | Engineering |

When working with aluminum extrusion tube profiles, understanding best practices can greatly enhance project outcomes. First and foremost, it is crucial to select the right profile for your specific application. Consider factors such as load-bearing capacity, shape, and environmental resistance. Each type of aluminum tube profile has unique characteristics that can significantly impact the overall performance of your project. Collaborating with suppliers who can provide technical assistance and insights into material properties can also streamline this process.

Another best practice is to prioritize proper machining and finishing techniques. Aluminum extrusion allows for a variety of processing options, from cutting to bending, which can help achieve the desired specifications. Ensure that your tools are compatible with aluminum to avoid damage during fabrication. Additionally, implementing quality control measures throughout the production cycle can mitigate errors and ensure the integrity of your finished product. Emphasizing these practices will not only save time and resources but also lead to more successful and durable outcomes in your aluminum extrusion projects.