In the world of architectural design and construction, Aluminum Moulding Profiles are increasingly becoming the go-to solution for both aesthetic appeal and practical functionality. Whether you're an architect, a contractor, or a DIY enthusiast, understanding the different types of moulding profiles available can significantly enhance your projects. This definitive ultimate guide will delve into the latest tips, trends, and techniques associated with Aluminum Moulding Profiles, offering you valuable insights into how to choose the right profiles for your specific needs. As we explore various applications and innovations in this field, you'll discover how Aluminum Moulding Profiles can transform spaces, elevate design, and provide long-lasting durability, making them essential components in modern construction. Join us as we navigate through the endless possibilities that these versatile profiles have to offer!

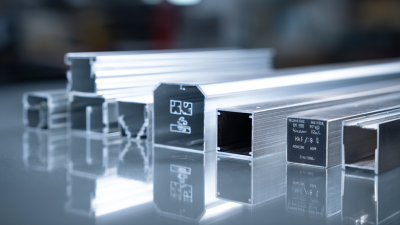

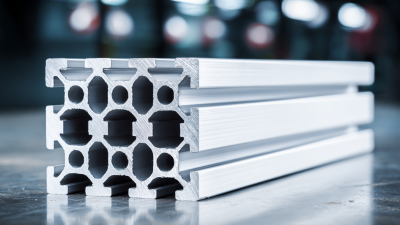

Aluminum moulding profiles have become increasingly popular in various industries due to their versatility, durability, and lightweight properties. These profiles are primarily categorized into several types such as structural, decorative, and functional. Structural profiles are often used in construction for framing and support, while decorative profiles enhance aesthetics in architectural designs. According to a recent industry report, the global aluminum moulding market is projected to grow at a CAGR of 5% from 2023 to 2030, driven by increased demand in residential and commercial applications.

When selecting aluminum moulding profiles, it's essential to consider their characteristics, including tensile strength, corrosion resistance, and finish options. Choosing the right profile can greatly impact the performance and longevity of the application. For instance, opting for anodized aluminum profiles not only enhances durability but also provides an attractive finish. A key tip is to always assess the environmental conditions where the profiles will be applied, as this will influence the type of treatment required for optimal performance.

Additionally, keeping up with trends in aluminum moulding can offer a competitive edge. Currently, the market is shifting towards eco-friendly and recycled aluminum options. Many manufacturers are investing in sustainable practices to meet consumer demands. When considering aluminum profiles, look for suppliers who prioritize sustainability, as this can also enhance your brand's reputation.

| Profile Type | Characteristics | Common Applications | Trends |

|---|---|---|---|

| Linear Profiles | Straight, versatile shapes suitable for framing | Doors, windows, and furniture | Minimalism and sustainability |

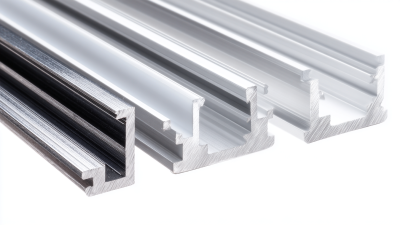

| Corner Profiles | L-shaped or U-shaped profiles for joining | Cabinetry and architectural edges | Angled designs for modern look |

| Custom Profiles | Tailored shapes for specific needs | Specialized installations and decorative trims | Unique designs and personalization |

| Angled Profiles | Profiles that can create depth and dimension | Interior design features and moldings | Integration of colors and textures |

| Decorative Profiles | Profiles with intricate designs | Crown moldings and architectural details | Revival of classic styles |

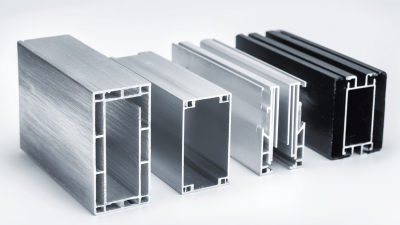

In the realm of modern design, aluminum moulding profiles have emerged as a versatile choice for various applications, reflecting key trends that emphasize both functionality and aesthetic appeal. One significant trend is the increasing preference for sleek, minimalistic designs that align with contemporary architectural styles. Designers are favoring clean lines and understated elegance, allowing aluminum moulding to complement rather than dominate space. This shift not only enhances the visual harmony of interiors but also reflects a growing demand for materials that convey a sense of sophistication.

Another prominent trend is the use of aluminum moulding in sustainable design practices. As more architects and designers prioritize eco-friendly approaches, aluminum’s recyclability makes it an attractive option. Its lightweight nature reduces transportation costs and energy consumption while maintaining durability and structural integrity. Additionally, innovations in powder coating techniques allow for a broader spectrum of colors and finishes, enabling personalization and customization that cater to modern consumer preferences. These developments signify a transformation in how aluminum moulding is perceived and utilized, showcasing its potential as both a functional and stylish element in today’s design landscape.

When it comes to fabricating and installing aluminum moulding profiles, attention to detail and proper techniques are essential for achieving a professional finish. One of the top techniques involves precise measuring and cutting. Always measure twice and cut once to reduce material waste and ensure fitting accuracy. Utilize high-quality saw blades designed for aluminum to achieve clean cuts, which will enhance the overall look of your project.

Another important tip is to consider the joining methods. Depending on the profile design and installation requirements, you might opt for welding, adhesive bonding, or mechanical fastening. Each method has its benefits; for instance, welding provides a seamless finish, while adhesives allow for greater flexibility in assembly. Whichever method you choose, ensure the surfaces are clean and properly prepared to maximize bond strength and durability.

Lastly, don't underestimate the importance of surface finishing. Anodizing or powder coating not only enhances the aesthetic appeal but also improves the corrosion resistance of aluminum profiles, which is vital for longevity. Ensure that you follow the manufacturer's instructions for surface treatment to achieve the best results and maintain the integrity of the material over time.

When it comes to maintaining and finishing aluminum moulding, adopting best practices is essential for achieving a polished and long-lasting result. First and foremost, regular cleaning is crucial. Aluminum is prone to oxidation, which can dull its shine and lead to corrosion over time. Using a soft cloth and mild detergent solution can effectively remove dirt and grime without damaging the surface. For more stubborn stains, a gentle abrasive cleaner or solution specifically designed for aluminum can be beneficial. Rinse thoroughly and dry to prevent water spots from forming.

In terms of finishing, applying a protective coating is highly recommended. This could include anodizing, which enhances corrosion resistance and provides a variety of color options, or painting with high-quality, weather-resistant paint. Both methods help to preserve the integrity of the aluminum and improve its visual appeal. It's also important to address scratches or chips promptly, as untreated damage can lead to further deterioration. Keeping an eye on these aspects will ensure that your aluminum moulding not only looks great but also stands the test of time.

Aluminum moulding profiles have become a staple in modern architectural design and interior decor, offering both versatility and sophistication. From sleek, minimalist lines to elaborate decorative trims, these profiles can transform any space. One innovative use is in ceiling designs; aluminum mouldings can create striking visual effects, accentuating height while adding an element of elegance. Consider incorporating dimmable LED lighting within the moulding to enhance the ambiance further.

When working with aluminum moulding, it's essential to keep a few tips in mind. First, always choose high-quality materials to ensure durability and longevity. Additionally, consider the finishes; powder-coating offers a variety of colors that can seamlessly integrate with your design theme. Finally, ensure precise measurements during installation to maintain clean lines and a polished look.

Another exciting trend is the use of aluminum moulding for cabinetry and furniture design. By adding profiles to edges, you can achieve a contemporary feel while protecting surfaces from wear and tear. Pairing aluminum with wood or glass elements can create a striking contrast, elevating the overall aesthetic of the space. Embrace this trend to achieve a unique, modern look in your home or project.