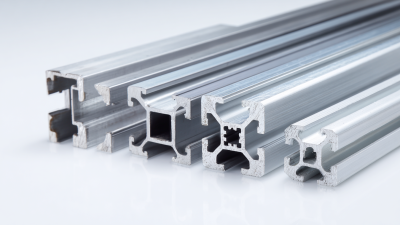

In the modern manufacturing landscape, the versatility of Standard Aluminum Extrusion Profiles has established them as a cornerstone in various industries, ranging from automotive to construction. According to a report by Global Market Insights, the aluminum extrusion market is projected to surpass $100 billion by 2027, driven by the rising demand for lightweight and durable materials. These profiles not only enhance the structural integrity of products but also offer significant design flexibility, making them ideal for custom applications. As organizations seek to optimize performance and reduce weight, understanding the diverse types of Standard Aluminum Extrusion Profiles and their applications becomes crucial for engineers and manufacturers alike. This comprehensive guide will explore the essential characteristics, benefits, and applications of these aluminum profiles, empowering you to make informed decisions in your projects.

Aluminum extrusion profiles have gained immense popularity across various industries due to their lightweight, durability, and versatility. According to a recent report by Grand View Research, the global market for aluminum extrusion is expected to reach USD 169.16 billion by 2025, driven by significant applications in sectors like construction, automotive, and electronics. These profiles are not only used for structural components but also for aesthetic finishes, showcasing their adaptability.

When selecting aluminum extrusion profiles for your application, consider the specific requirements of your industry. For instance, in the automotive sector, where weight reduction is essential for enhancing fuel efficiency, utilizing profiles designed specifically for structural integrity can result in both performance gains and cost savings. Additionally, industries such as HVAC benefit from aluminum’s thermal conductivity, allowing for efficient heat transfer in systems.

**Tip:** Always collaborate with a supplier that offers customized extrusion options to meet the unique specifications of your projects. This ensures that the finished product will adhere to the functional and aesthetic criteria needed for your specific application. Moreover, regularly reviewing industry reports can keep you informed about the latest trends and innovations in aluminum extrusion, aiding better decision-making for future projects.

This bar chart illustrates the applications of standard aluminum extrusion profiles across different industries, showcasing their versatility and usage frequency.

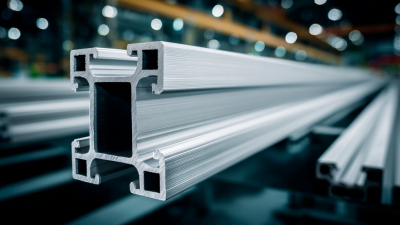

Aluminum extrusion profiles play a pivotal role in construction and architecture, providing versatile and lightweight solutions for various applications. From structural frameworks to decorative elements, these profiles can enhance both functionality and aesthetics in any project. For instance, curtain walls benefit immensely from aluminum extrusions due to their durability and ability to withstand environmental stresses, while also allowing natural light to permeate indoor spaces.

Tips for selecting the right aluminum extrusion profile include considering factors such as strength-to-weight ratio, corrosion resistance, and thermal performance. It's essential to evaluate the specific needs of your project to ensure optimal performance. Additionally, taking advantage of the customization options offered by manufacturers can lead to innovative design solutions that closely match your architectural vision.

In interior design, aluminum extrusion profiles can be utilized for trim, partitions, and even furniture, providing sleek lines and seamless finishes. When planning your design, think about how these profiles can be integrated into modern and minimalist aesthetics to achieve a cohesive look. Exploring the diverse possibilities of aluminum extrusions can unlock new creative avenues in construction and architectural design.

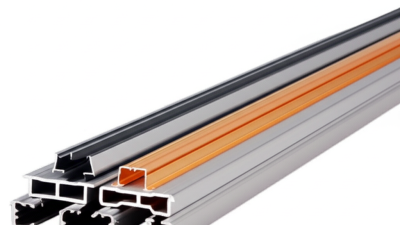

When it comes to automotive manufacturing, selecting the right aluminum extrusion profile is crucial for achieving optimal performance and durability. Aluminum extrusions offer a versatile solution for various components due to their lightweight nature and high strength-to-weight ratio. In the automotive industry, specific profiles can enhance structural integrity, improve fuel efficiency, and meet stringent safety standards. The choice of extrusion profile must consider factors such as load-bearing requirements, corrosion resistance, and design complexity.

Automotive manufacturers are increasingly leaning towards customized aluminum extrusion profiles to meet their unique needs. These profiles can be designed to fit specific application requirements, enabling streamlined assembly and reduced weight without sacrificing rigidity. Moreover, innovation in aluminum extrusion methods allows for enhanced features such as integrated mounting points, cooling channels, and aerodynamics, making them ideal for modern vehicle designs. By actively engaging with extrusion specialists, manufacturers can ensure they select profiles that not only comply with industry standards but also leverage the latest advancements in material technology.

Aluminum extrusions are increasingly becoming essential components in the electronics and technology sectors. Their versatility makes them suitable for various applications, from heat sinks in devices to structural supports in complex machinery. The booming demand for lightweight and durable materials continues to drive innovation, fueling the aluminum extrusion market's growth globally. Recent forecasts indicate significant expansion, particularly in the Asia-Pacific region, which is anticipated to witness remarkable growth rates, reaching substantial market sizes by 2035.

When exploring innovative uses for aluminum extrusions, one key tip is to consider the thermal conductivity of aluminum, which makes it ideal for electronic heat management. Utilizing custom profiles can enhance efficiency and improve the overall performance of electronic devices. Additionally, incorporating eco-friendly production methods not only aligns with sustainability trends but also attracts conscious consumers.

Another important aspect is the integration of aluminum extrusions in advanced technological applications, such as medical devices and renewable energy solutions. Focusing on the adaptability of extrusion shapes allows engineers to create optimized designs tailored to specific needs, paving the way for smarter, more efficient products in the market. Remember, staying updated with industry trends can provide valuable insights into upcoming opportunities within this dynamic landscape.

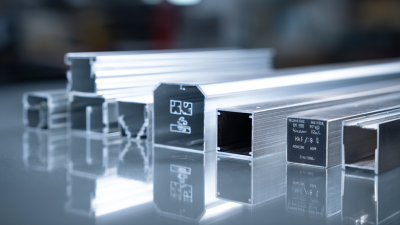

When it comes to specialized industrial applications, customizing standard aluminum profiles can significantly enhance operational efficiency and product performance. According to a report by the Aluminum Association, the global aluminum extrusion market is projected to reach $73 billion by 2026, driven by increasing demand in sectors such as automotive, aerospace, and construction. Customizing standard aluminum profiles allows manufacturers to meet specific requirements, which can lead to improved product life cycles and reduced material waste.

For instance, industries that require unique shapes for structural support or thermal management find that tailored aluminum profiles can deliver enhanced mechanical properties and weight savings. A study by MarketsandMarkets indicates that the demand for lightweight materials, including aluminum, in the automotive industry alone is expected to grow at a compound annual growth rate (CAGR) of 5.7% from 2021 to 2026. This highlights the urgency for manufacturers to adapt standard profiles to cater to the evolving needs of high-performance applications, ultimately leading to cost-effective and sustainable production strategies.