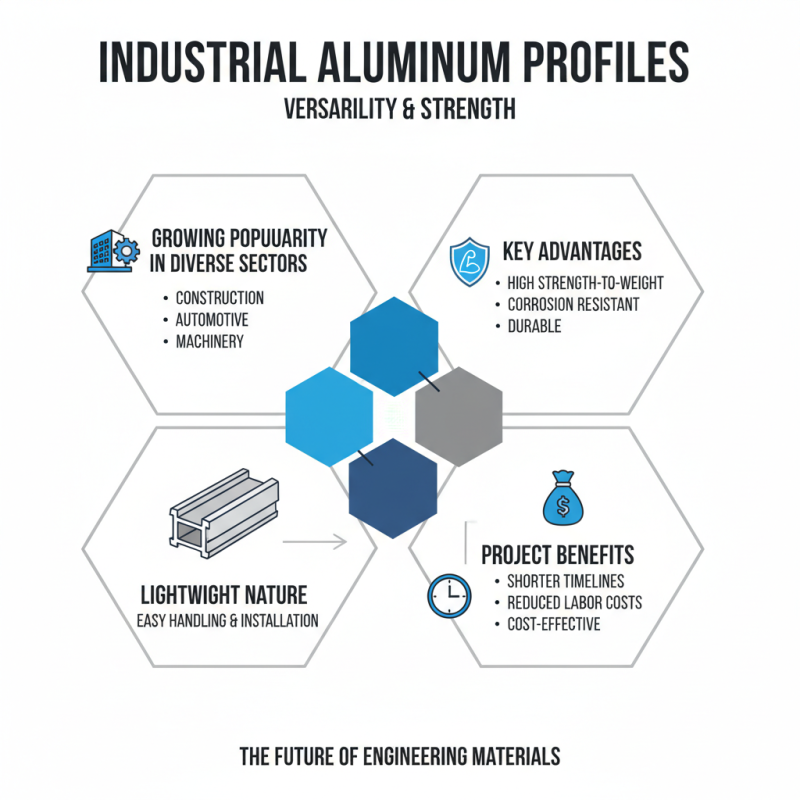

Industrial Aluminum Profiles have become a cornerstone in modern manufacturing. Experts like John Smith, a leading engineer in this field, emphasize their importance: "Industrial Aluminum Profiles are redefining efficiency and strength." These profiles are versatile, adaptable, and essential in various applications.

The benefits of using Industrial Aluminum Profiles are significant. They offer excellent strength-to-weight ratios. This means less material is needed without compromising durability. Manufacturers can optimize designs easily. The profiles are also cost-effective in the long run, saving money on labor and materials.

However, challenges exist. Some engineers worry about the initial costs. Others may struggle with knowledge gaps in their teams. This could limit the potential benefits. Awareness of these issues is vital for effective implementation. Keeping these considerations in mind can enhance the advantages of Industrial Aluminum Profiles.

Industrial aluminum profiles are increasingly popular in various sectors. These profiles are known for their versatility and strength. They can be found in construction, automotive, and machinery applications. The lightweight nature of aluminum makes it easy to handle and install. This can lead to shorter project timelines and reduced labor costs.

When choosing aluminum profiles, consider the intended application. Profiles come in various shapes and sizes, which offer unique benefits. Ensure you select a profile that meets your structural and aesthetic needs. Customization options are available, allowing for tailored solutions in design. Think about how different finishes can impact the final look and durability.

Tips: Always evaluate the environmental impact of your materials. Aluminum is recyclable, which adds to its allure. However, check the life cycle assessment of your chosen profiles. Ensure that your selection aligns with sustainability goals. Also, keep in mind that not all aluminum is created equal. Test for quality and reliability before committing to a large order. These steps can save time and resources in the long run.

Aluminum is widely recognized for its unique properties, which significantly enhance industrial applications. Its lightweight nature makes it an ideal choice for structures that require strength without heavy materials. For instance, in construction, aluminum profiles can support considerable weight while remaining easy to handle. This contributes to efficient assembly processes and reduces labor costs.

Another crucial property of aluminum is its resistance to corrosion. This is particularly beneficial in environments where exposure to moisture and chemicals is frequent. Using aluminum profiles can extend the lifespan of equipment, which results in lower maintenance costs. However, one must consider that while aluminum is resistant to rust, it can still be affected by certain elements, prompting the need for proper treatment.

Additionally, aluminum's versatility allows for a range of customizations. Different shapes and sizes cater to specific industrial needs. From automotive frames to structural supports, the adaptability of aluminum is evident. Nevertheless, achieving the desired strength and durability can sometimes require trial and error. It’s vital to reflect and adjust designs accordingly for optimal performance.

Industrial aluminum profiles offer significant cost efficiency. These materials are lightweight and durable, reducing transportation costs. Their strength allows for thinner designs, which can save on material expenses. Manufacturing processes can leverage these profiles, minimizing wasted resources.

Companies can save on maintenance costs too. Aluminum often requires less upkeep compared to other materials. This durability leads to fewer replacements and repairs. However, initial investments in aluminum profiles may seem high. It requires careful budgeting and analysis to see the long-term benefits clearly.

Moreover, the versatility of aluminum profiles enables innovative design solutions. They can be easily adapted for various applications. Yet, if not planned properly, production delays can lead to unexpected expenses. A thorough understanding of needs is essential to maximize savings. Careful consideration can provide the anticipated cost benefits while avoiding potential pitfalls.

This chart illustrates the top 10 benefits of using industrial aluminum profiles, highlighting features such as lightweight, corrosion resistance, and cost efficiency. Each benefit is rated on a scale from 1 to 10 based on its significance in industrial applications.

Industrial aluminum profiles have become increasingly significant across multiple sectors. Their versatility in design opens the door to countless applications. In automotive manufacturing, for example, aluminum profiles reduce weight, enhancing fuel efficiency. A report from the International Aluminum Institute shows that cars constructed with aluminum can achieve up to 30% improvement in mileage.

In the construction industry, aluminum profiles are favored for their strength and durability. They can be easily customized to fit architectural needs. According to a McKinsey study, using aluminum in construction projects can lead to a reduction in material waste by approximately 50%. This not only benefits the environment but also contributes to cost savings.

However, some challenges need attention. The initial cost of aluminum profiles can be higher than other materials. Furthermore, the requirement for specialized manufacturing processes creates barriers for smaller businesses. As industries evolve, companies must navigate these hurdles to fully harness the potential of aluminum profiles. Balancing quality, cost, and sustainability remains a critical focus for ongoing innovation in aluminum applications.

| Benefit | Description | Applications |

|---|---|---|

| Lightweight | Aluminum profiles are significantly lighter than steel profiles, reducing transportation and handling costs. | Aerospace, Automotive |

| Corrosion Resistance | Aluminum naturally forms a protective oxide layer, preventing oxidation and corrosion. | Marine, Construction |

| Versatility in Design | Can be easily extruded into complex shapes for various design requirements. | Architecture, Furniture |

| Sustainability | Aluminum is 100% recyclable, preserving natural resources and reducing environmental impact. | Packaging, Renewable Energy |

| Thermal Conductivity | Good heat conductivity makes aluminum ideal for heat exchangers and thermal management. | HVAC, Electronics |

| Strength-to-Weight Ratio | Offers a high strength-to-weight ratio, making it suitable for structural applications. | Construction, Transportation |

| Customizability | Aluminum profiles can be customized in size and finish according to specific needs. | Manufacturing, Retail |

| Low Maintenance | Requires minimal maintenance compared to other metals due to its corrosion resistance. | Outdoor Structures, Signage |

| Cost-Effectiveness | Competitive material costs when considering lifecycle and maintenance costs. | Industrial Applications, Packaging |

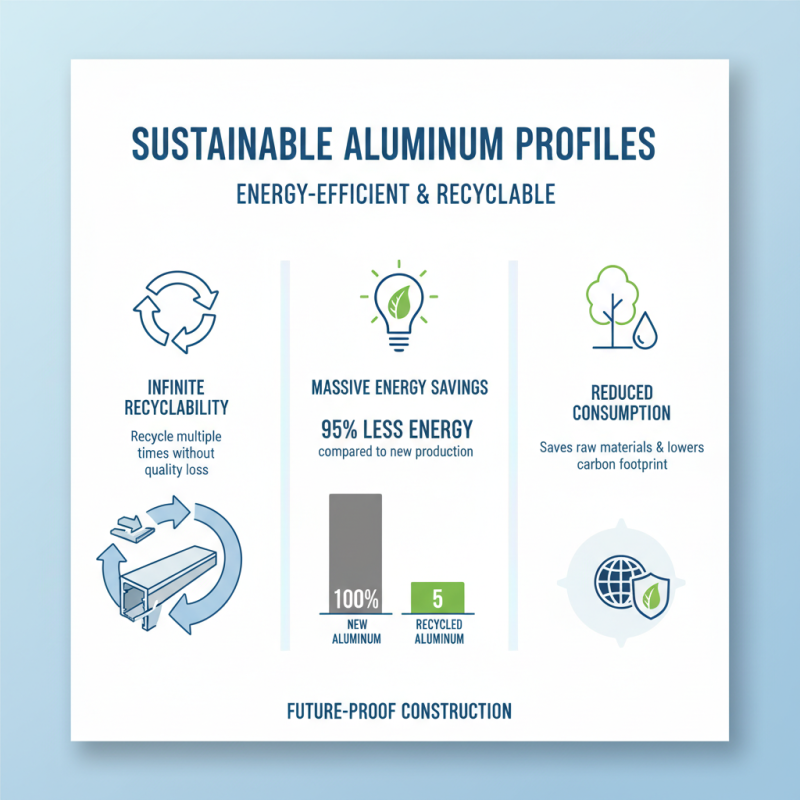

Aluminum profiles are gaining popularity due to their sustainable characteristics. One significant benefit is their recyclability. Aluminum can be recycled multiple times without losing quality. This process saves energy and reduces raw material consumption. Recycling aluminum uses only 5% of the energy needed to produce new aluminum.

Sustainability is another aspect of aluminum profiles. They are lightweight, which means less energy is required for transportation. Their long lifespan also contributes to lower environmental impacts. However, the extraction of aluminum can be harmful. It often involves mining practices that destroy habitats. This raises questions about the balance between benefits and environmental costs.

Using aluminum in construction and manufacturing can lead to greener solutions. It is essential to consider the entire lifecycle of the material. Being aware of its pros and cons helps make informed decisions. Striving for a sustainable future means reevaluating our material choices. By understanding aluminum's impact, we can harness its potential responsibly.