Aluminum Corner Extrusion Profiles are essential in various industries. These profiles play a key role in enhancing structural integrity and design. As we approach 2026, understanding their significance is paramount.

In the world of construction and manufacturing, the right profiles can make all the difference. Architects and engineers increasingly prefer aluminum for its lightweight nature and durability. However, choosing the right Aluminum Corner Extrusion Profiles isn’t easy. There are numerous options, and not all may fit your project needs perfectly.

It’s important to consider specific factors. Quality, finish, and dimensions matter greatly. Each choice can impact the overall outcome of a project. Be aware that imperfections in profiles can lead to structural issues. Identifying the most suitable profiles for your work is crucial, as it reflects on durability and aesthetics. Reflecting on past projects can also help in making better decisions.

Aluminum corner extrusion profiles play a crucial role in various industries. These profiles are widely used in construction, automotive, and electronics. The global aluminum extrusion market is expected to reach $133 billion by 2026, according to industry reports. This growth indicates a rising demand for lightweight and durable materials.

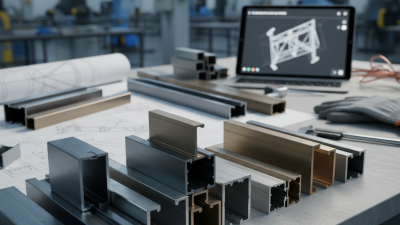

Understanding the specifications of aluminum corner extrusion profiles is essential. They come in various shapes, sizes, and thicknesses. Common forms include L-shaped and U-shaped profiles. Each design serves specific applications. Moreover, the customization of these profiles allows manufacturers to meet unique project requirements. However, many still overlook the importance of quality standards.

Some profiles may not meet expected tolerances. This can lead to structural issues in the final product. Additionally, the recycling aspect of aluminum makes it an eco-friendly option. However, not all aluminum is recycled properly, leading to waste. To fully appreciate aluminum corner extrusions, one must consider both their advantages and potential drawbacks in practical use. Understanding this balance is key to effective application.

Aluminum corner extrusions are increasingly favored in construction due to their numerous benefits. According to a report by the Aluminum Association, aluminum's lightweight nature provides significant advantages over traditional materials. It is about one-third the weight of steel, making transport and installation easier. This weight reduction can lead to a decrease in overall project costs.

The durability of aluminum is another key factor. Extrusions are resistant to corrosion, which is crucial in various climates. A study by the International Aluminum Institute notes that aluminum can last over 50 years in harsh conditions. In construction, this longevity translates to lower maintenance costs and less frequent replacements. However, some challenges exist, such as the need for special coatings to enhance corrosion resistance in specific environments.

Energy efficiency is an important consideration as well. Aluminum corner extrusions can optimize thermal performance when integrated properly. According to the U.S. Department of Energy, energy-efficient buildings can save up to 30% on heating and cooling costs. Still, it’s vital to ensure proper design and placement, as inefficient installations can negate these benefits. Balancing these advantages with potential drawbacks is essential for successful projects.

Aluminum corner extrusion profiles are versatile components across various industries. They are widely used in construction, furniture, and manufacturing. An industry report indicates that the global demand for aluminum extrusions is expected to reach 70 million tons by 2026. This growth is driven by advancements in design and technology.

In construction, these profiles provide structural support and framing. They create strong connections in window and door assemblies. The automotive sector also utilizes aluminum corner extrusions for lightweight designs. This reduces fuel consumption. However, while these profiles are increasingly important, some manufacturers struggle with quality control. Subpar extrusions can lead to issues like misalignment and structural weaknesses. Proper testing and quality assurance are crucial.

Furniture designs have also embraced aluminum corner profiles. They are used in tables, chairs, and shelving units. Their modern aesthetic appeals to many consumers. An estimated 25% of new furniture designs now feature aluminum components. Yet, not all designs consider user ergonomics. It's essential to balance style with comfort and usability. This is an ongoing challenge in the industry.

Choosing the right aluminum corner extrusions can be a challenging process. Consider the application where you will use them. Are they for structural support or aesthetic purposes? Different uses require different properties. Extrusions that are lightweight may not always provide the strength needed for heavy-duty applications.

**Tip:** Always match the extrusion profile to your specific application. This will help in achieving desired performance and longevity.

Next, think about the finish. Anodizing offers durability and a visually appealing surface. However, it might not be the best choice for all environments. If the extrusions will face harsh conditions, investigate powder coating or other treatments. Each finish has its advantages and potential drawbacks.

**Tip:** Test the finish in relevant conditions before finalizing your choice. The surface treatment can significantly affect both appearance and function.

Lastly, consider the manufacturing process. Some profiles might be better suited for specific methods. For instance, complex designs may require more precise tooling. This can lead to longer lead times or additional costs. Evaluate if you are ready for this kind of investment.

**Tip:** Engage with a professional to discuss your design goals. It's okay to ask questions and voice concerns about the extrusion's performance.

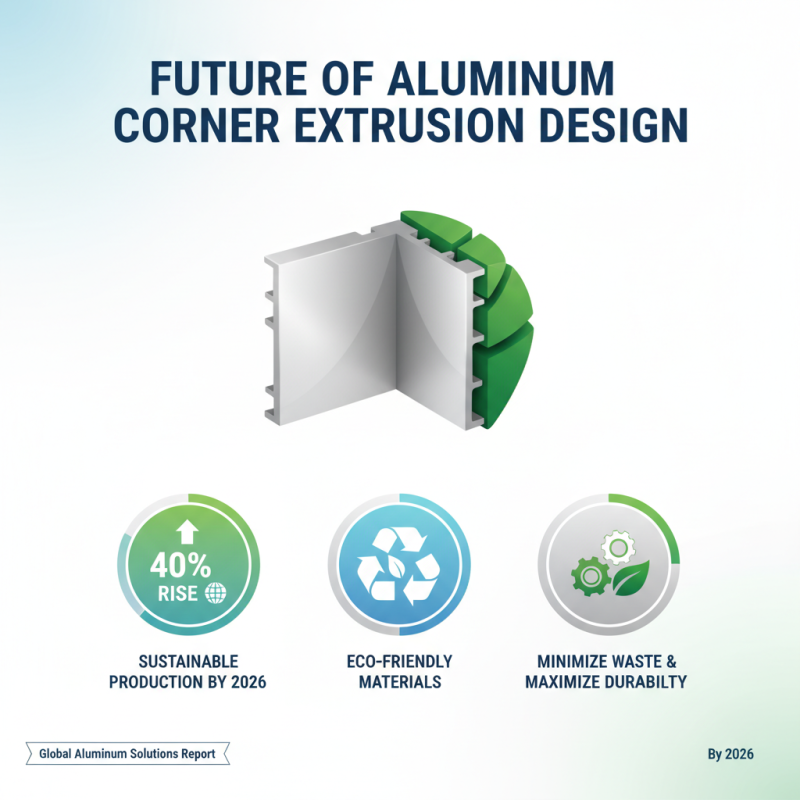

The future of aluminum corner extrusion design is evolving rapidly. The industry predicts a shift towards more sustainable practices. According to a recent report from Global Aluminum Solutions, by 2026, sustainable aluminum production could rise by 40%. This increase aligns with global demands for eco-friendly materials. Designers are now focusing on minimizing waste while maximizing durability.

Innovations in technology are shaping the manufacturing process. 3D printing is gaining traction in creating intricate designs. This method reduces material waste significantly. Additionally, the integration of advanced software allows for precision in extrusion profiles. Designers can visualize and modify their projects in real-time, enhancing creativity.

Tips: When considering aluminum corner extrusions, think about the lifecycle of the material. Look for options that offer recycling capabilities. Also, stay updated on industry trends that may impact design choices. Embrace flexibility in your designs, allowing for future updates or modifications where necessary. Always question your choices and seek improvements.