In the world of manufacturing, Aluminum Channel Extrusion Profiles play a crucial role. These versatile profiles are integral to various industries, from construction to transportation. Expert John Smith, a seasoned engineer, points out, “The right extrusion profile can optimize efficiency in any project.” His words highlight the necessity for careful selection in design.

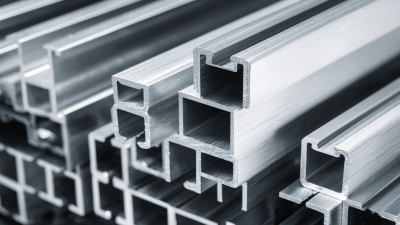

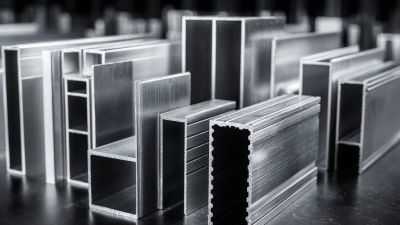

Aluminum Channel Extrusion Profiles come in various shapes and sizes. Each profile serves different purposes; knowing the top options is vital. For instance, certain channels are ideal for framing, while others excel in electrical enclosures. Choosing the wrong type can lead to structural failures or increased costs. In this competitive market, understanding these profiles is essential.

However, the knowledge is often overlooked. Many professionals may not realize how varying profiles impact project outcomes. It’s important to reflect on these choices. Making informed decisions will lead to better results, enhancing both functionality and aesthetic appeal.

Aluminum channel extrusions play a vital role in various industries. They are lightweight but strong, offering both flexibility and durability. These profiles are commonly used in construction, automotive, and manufacturing sectors. Their unique shapes allow for easy assembly and modification. From framing structures to supporting components, these extrusions cater to diverse applications.

The importance of aluminum channel extrusions cannot be overstated. They enhance structural integrity while reducing weight in products. Their resistance to corrosion ensures longevity, making them a preferred choice for many projects. However, the choices in design and application often lead to uneven results. Not every extrusion meets the specific needs of a project. This area requires careful consideration and testing to ensure performance aligns with expectations.

In creating custom solutions, challenges often arise. Sometimes, the desired weight or strength is sacrificed. Continual reflection on design choices is essential for optimal outcomes. Misalignment between requirements and available profiles can lead to inefficiencies. Industry experts must stay informed and adaptive to overcome these issues. This proactive approach is key in maximizing the advantages of aluminum channel extrusions.

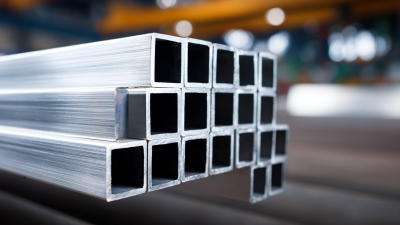

Aluminum channels are essential in various industries, thanks to their remarkable properties. One key aspect is their strength. According to a recent industry report, aluminum alloys can achieve strengths up to 700 MPa. This makes them suitable for structural applications, where durability is crucial. Yet, not all aluminum channels share the same strength. It's vital to choose the right alloy for the specific application.

Weight is another significant advantage of aluminum channels. They are lighter than many alternatives, reducing overall project weight. For example, an aluminum channel can weigh approximately 2.8 grams per centimeter. This lightweight feature aids in easier handling and installation, but it may raise questions about their load-bearing capacity. Engineers must carefully evaluate the channel design.

Corrosion resistance is a standout characteristic of aluminum. It naturally forms a protective oxide layer that shields it from corrosion. Data indicates that treated aluminum channels resist corrosion in harsh environments, outperforming mild steel. However, this resistance can be compromised without proper finish or maintenance. Understanding these limits is essential for long-term performance. The decision to use aluminum should consider specific project needs and potential external factors.

Aluminum channel profiles are versatile and widely used across various industries. They play a crucial role in construction, automotive, and manufacturing. In construction, these profiles provide structural support for frames and barriers. You often see them in bridges and building facades, where strength is paramount.

In automotive applications, aluminum channels are used for lightweight structures. They help improve fuel efficiency while maintaining safety. These profiles are commonly found in car frames and body panels. Their resistance to corrosion makes them suitable for various environments.

**Tip:** When choosing aluminum profiles, consider the weight and size. This will affect the overall structure and efficiency.

In manufacturing, aluminum channels support assembly lines and conveyor systems. They help create durable frameworks for machinery. However, it's essential to reflect on the quality. Not all suppliers meet the same standards.

**Tip:** Inspect profiles for defects before use. This can save time and costs in the long run. Consider how these profiles integrate with other components in your project.

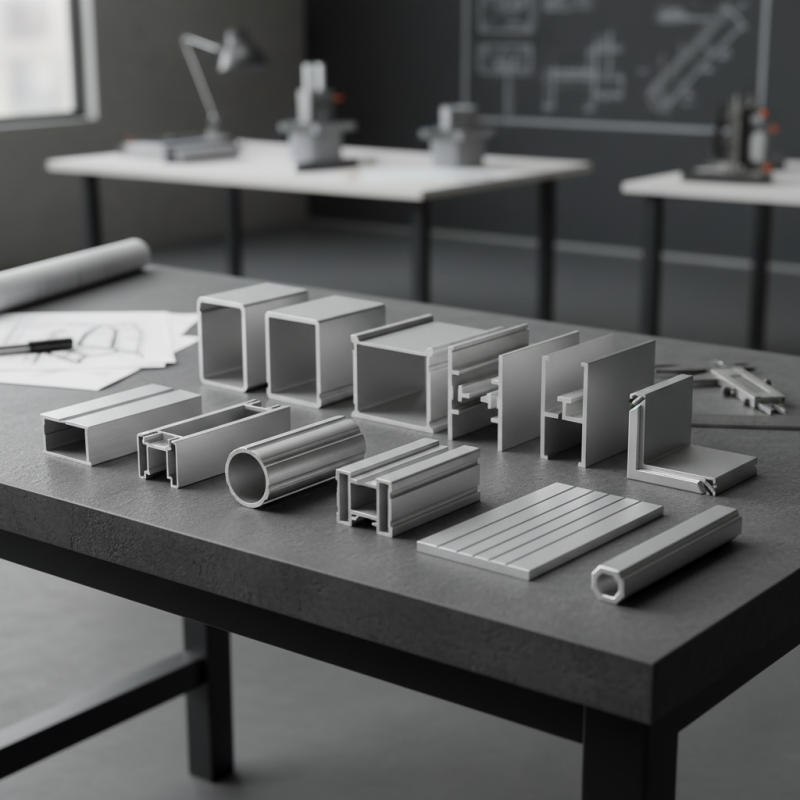

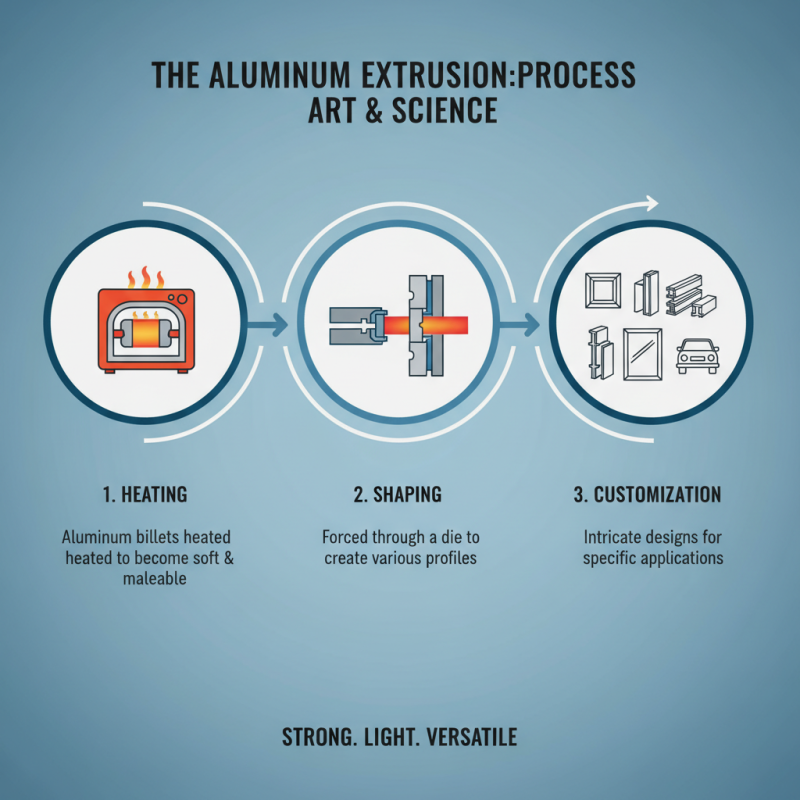

The manufacturing process of aluminum extrusions combines art and science. It begins with heating aluminum billets in a furnace. These billets soften, making them malleable for shaping. The heated aluminum is then forced through a die, creating various profiles. This method allows for intricate designs tailored to specific applications.

When working with aluminum extrusions, precision is crucial. Small changes can lead to significant differences in the final product. Pay attention to the temperatures used in the process. Too high or too low can affect the extrusion quality. Every detail matters here.

**Tips:** Ensure your dies are in good condition. Replacing worn-out dies can save time and material costs. Regular maintenance of the extrusion machine can prevent production delays. Always document variations in temperatures or materials used. This practice helps improve future productions.

The aluminum channel extrusion market is experiencing notable growth. Industries are increasingly adopting aluminum due to its advantages. Lightweight yet strong, aluminum is ideal for various applications. Products like building materials and furniture components benefit from its unique properties.

Innovations in this sector are transforming designs. New techniques enhance the efficiency of production. Additive manufacturing and precision engineering are gaining traction. These technologies allow for complex designs that traditional methods cannot achieve. However, challenges remain in standardizing process quality and material consistency.

Sustainability is also a significant focus. More manufacturers are looking for eco-friendly solutions. Recycling aluminum reduces waste and energy consumption. Yet, not all producers prioritize this aspect. Emphasizing sustainable practices should not be overlooked. More awareness is crucial for driving positive industry change.