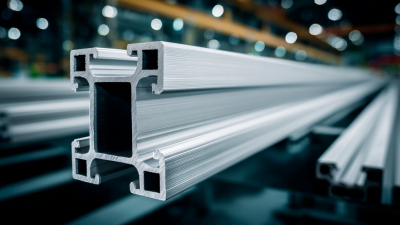

When considering the optimal design for electronic enclosures, "Extruded Aluminum Enclosure Profiles" stand out as a top choice across various industries. A recent industry report by the Aluminum Association indicates that the use of aluminum profiles in manufacturing has surged by 30% in the past five years. This growth reflects the material's lightweight, durability, and resistance to corrosion, making it ideal for various applications.

Expert John Smith, a notable figure in the enclosure design industry, emphasizes, "Extruded Aluminum Enclosure Profiles offer unmatched versatility and long-term cost savings." His insights highlight the importance of selecting profiles that align with specific project needs. However, selecting the best profile can be challenging given the myriad options available. Companies must carefully evaluate their designs, applications, and budget constraints to make informed decisions.

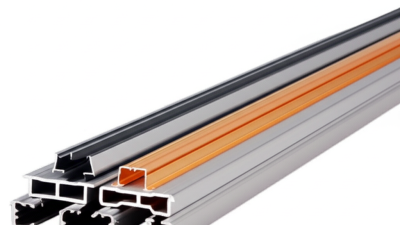

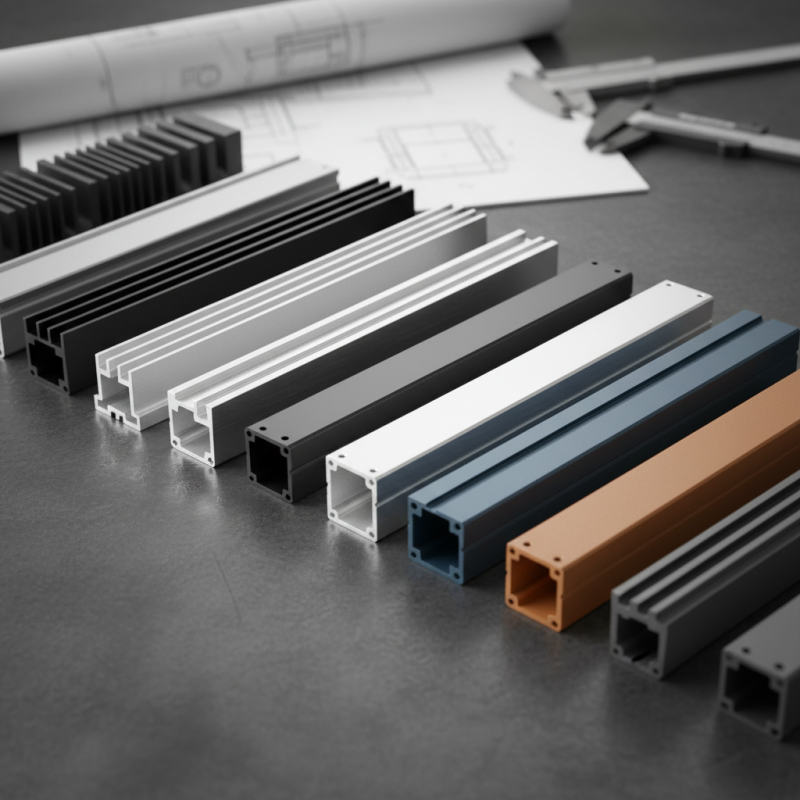

The diversity of "Extruded Aluminum Enclosure Profiles" can be overwhelming. Each profile serves different needs, from heat dissipation to aesthetic considerations. While many options exist, the right choice depends on careful analysis of potential trade-offs and project requirements.

When it comes to electronics applications, choosing the right enclosure is crucial. Extruded aluminum profiles provide a durable, lightweight solution. They offer excellent thermal management and are resistant to corrosion. Many profiles are customizable, allowing designers to achieve the desired look and feel.

One popular choice is the flat panel profile. This option provides a sleek design, ideal for modern electronics. Another option is the deep section profile. It allows for more internal space, accommodating larger components. Despite these advantages, some users find installation can be challenging. Proper alignment is key for optimal functionality.

The channel frame profile is great for unique shapes. It allows for creative designs while maintaining strength. However, modifying these profiles can be complex. Users must consider this when planning their project. Choosing the right profile requires careful thought. Balancing functionality and aesthetics is not always straightforward.

| Profile Name | Dimensions (mm) | Weight (kg/m) | Applications | Finish Options |

|---|---|---|---|---|

| Aluminum Profile A | 40 x 40 | 2.2 | Industrial electronics | Anodized, Powder Coated |

| Aluminum Profile B | 60 x 40 | 3.0 | Consumer electronics | Brushed, Anodized |

| Aluminum Profile C | 80 x 40 | 4.0 | Telecommunications | Powder Coated, Mill Finish |

| Aluminum Profile D | 100 x 50 | 5.5 | Data storage solutions | Anodized, Powder Coated |

| Aluminum Profile E | 120 x 60 | 6.3 | Medical devices | Brushed, Anodized |

| Aluminum Profile F | 150 x 80 | 7.2 | Robotics | Powder Coated, Mill Finish |

| Aluminum Profile G | 200 x 100 | 9.0 | Aerospace | Anodized, Brushed |

| Aluminum Profile H | 250 x 120 | 10.5 | Automotive | Powder Coated, Anodized |

| Aluminum Profile I | 300 x 150 | 12.0 | Military | Brushed, Mill Finish |

| Aluminum Profile J | 350 x 200 | 14.3 | Renewable energy systems | Anodized, Powder Coated |

When choosing extruded aluminum enclosures, look for key characteristics that indicate quality. A durable finish often signifies longevity. Anodized surfaces resist corrosion and wear. This can extend the lifespan of your enclosure significantly. Make sure to select profiles that offer optimal thermal management. Proper heat dissipation is crucial for electronic components.

Tip: Consider the environment where the enclosure will be used. Harsh environments demand stronger materials and protections. Check for IP ratings to ensure your enclosure can withstand dust and moisture.

Another vital aspect is customization options. Look for enclosures that allow easy modifications. Flexibility in design can save time and costs in future projects. Ensure that the profiles you choose provide enough internal space for your components. Overcrowding can lead to overheating and malfunction.

Tip: Plan for future upgrades. It’s wise to choose designs that can accommodate changes without requiring a complete redesign. This foresight could prevent unnecessary hassle down the line.

Thermal management is crucial for the performance of aluminum enclosure profiles. High thermal conductivity is one advantage of aluminum. According to industry reports, the thermal conductivity of aluminum can reach 205 W/m·K. This property helps dissipate heat effectively, preventing overheating of electronic components. However, not all profiles utilize this potential.

Different profiles exhibit varying thermal management capabilities. Some designs incorporate fins or channels to enhance airflow, while others offer smooth surfaces. A comparative analysis shows that profiles with larger surface areas can boost heat dissipation by up to 30%. But is a larger surface always better? Complexity in design may lead to manufacturing challenges.

Choosing the right profile means balancing aesthetics, performance, and practicality. A less intricate design might save costs. However, it may not provide adequate thermal management. Overheating issues could arise in high-demand applications, leading to failures. Each design decision matters. The trade-offs between style and function require careful consideration.

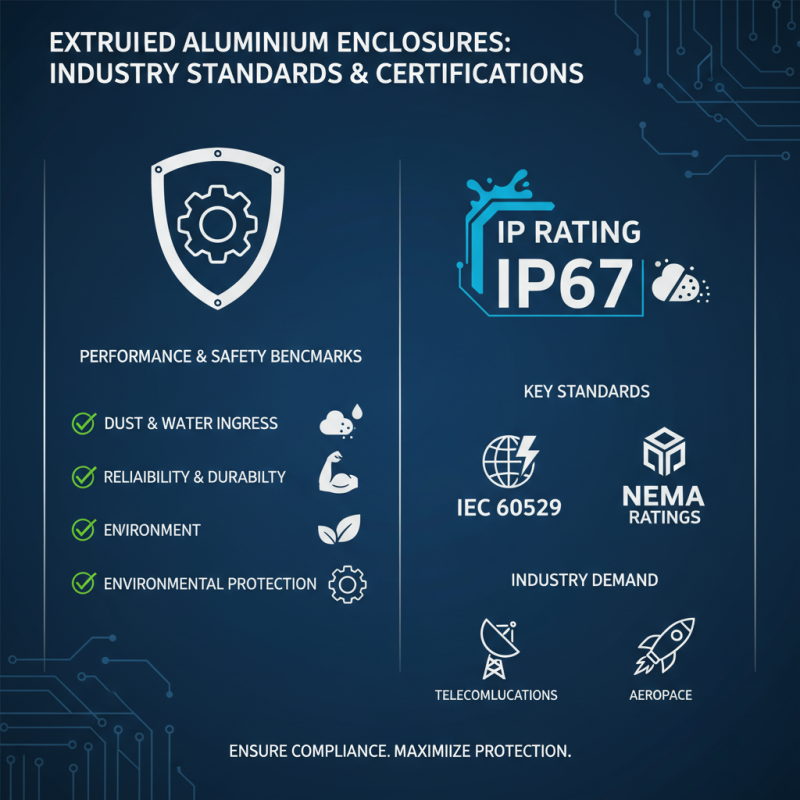

When selecting extruded aluminum enclosures, it’s crucial to understand the relevant industry standards and certifications. Many reports show that enclosures must meet both performance and safety benchmarks. Standards like IEC 60529 and NEMA ratings are essential for defining the protection level against dust and water ingress. For example, an IP67 rating indicates a high level of water resistance. This level often spurs demand in industries like telecommunications and aerospace.

Moreover, certifications such as UL and CE enhance credibility and safety. According to a recent market study, nearly 70% of manufacturers prefer using certified components. This trend ensures end products are reliable and meet international safety guidelines. However, it’s vital to remember that not all products might meet these standards. Some may lack proper documentation or testing, leading to catastrophic failures down the line.

While many organizations strive to comply with industry standards, achieving full compliance is sometimes an uphill battle. Test results can vary. Sometimes, discrepancies arise between reported and actual performance. It’s necessary to evaluate these claims critically. Companies must invest time in due diligence to safeguard their operations and customers.

When choosing extruded aluminum enclosure profiles, cost-effectiveness and longevity are crucial factors. According to a report by the Aluminum Association, aluminum profiles can offer up to a 30% cost reduction compared to other materials. This is largely due to lower maintenance costs and longer life cycles. Aluminum is resistant to corrosion, which adds to its durability. An average aluminum enclosure can last over 25 years in adverse conditions.

Tip: Consider reusing aluminum enclosures whenever possible. They can often be repurposed, which further reduces costs and waste.

Different extrusion profiles also have varying degrees of strength. Some thinner profiles may save on material costs but could compromise performance. The right balance between thickness and design is essential. A detailed comparison of profile designs can impact both the budget and the longevity of the enclosures.

Tip: Consult with technical experts to understand the mechanical properties of various profiles. This ensures that you select the most suitable profile for your needs.

Investing in high-quality profiles may seem pricier upfront but often pays off. The total cost over time tends to favor stronger, well-designed extrusions. Always weigh short-term savings against long-term value.