When selecting Aluminum Construction Profiles, one navigates a complex landscape of choices. These profiles are integral to modern construction, providing strength and versatility. According to a report by Allied Market Research, the global aluminum extrusion market is expected to reach $82.2 billion by 2027. This surge reflects the increasing demand for light-weight and durable materials in building projects.

Understanding the specifications of Aluminum Construction Profiles can significantly impact project outcomes. There is a notable trend toward using recycled aluminum, emphasizing sustainability. A study by the International Aluminum Institute states that recycling aluminum saves up to 95% of energy compared to producing new aluminum. However, not all suppliers adhere to these sustainable practices, which can lead to inconsistencies in quality.

Cost is another critical factor. Prices for aluminum profiles can fluctuate due to market dynamics and regional availability. Buyers must conduct thorough research. Without careful consideration, one might overlook pivotal details. Misjudging the quality or type of profile can lead to structural issues down the line. Hence, vigilance is essential when making decisions regarding Aluminum Construction Profiles.

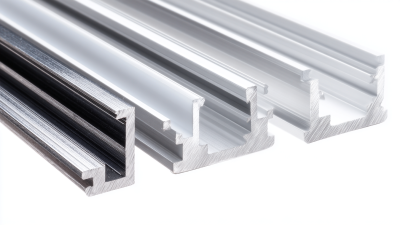

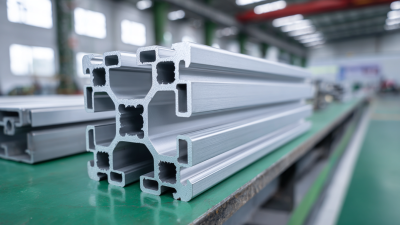

When choosing aluminum construction profiles, understanding the basic types is crucial. There are several types of profiles available in the market. Each type serves a different purpose in construction. Common types include structural angles, channels, and tubes. Each design comes with unique characteristics and applications.

Profiles like structural angles are often used for frames and support. They provide strength and durability. Channels, on the other hand, are versatile and can be used in various projects. They offer effective solutions for structural support and pathways. Tubes lend a modern aesthetic. They are commonly seen in railings and furniture.

When selecting aluminum profiles, consider quality and strength. Look for profiles that meet your project's specific needs. Also, evaluate the environment where they will be installed. Some profiles work better under certain conditions. Ensure they are not prone to corrosion or wear. Remember, price does not always reflect quality. Be cautious of deals that seem too good to be true.

| Profile Type | Applications | Advantages | Considerations |

|---|---|---|---|

| Square Profiles | Frameworks, Furniture, Railing | High strength, Easy to connect | Weight considerations |

| Rectangular Profiles | Structural support, Housing | Versatile, High structural integrity | May require additional fastening |

| T- Profiles | Frameworks, Supports | Resistance to bending, Easy to install | Limited load capacity |

| L-Profiles | Corner brackets, Frames | Space-efficient, Lightweight | Potential stability issues for large spans |

| U-Profiles | Channels, Supports | Good for conduit and pipes | Limited structural capacity |

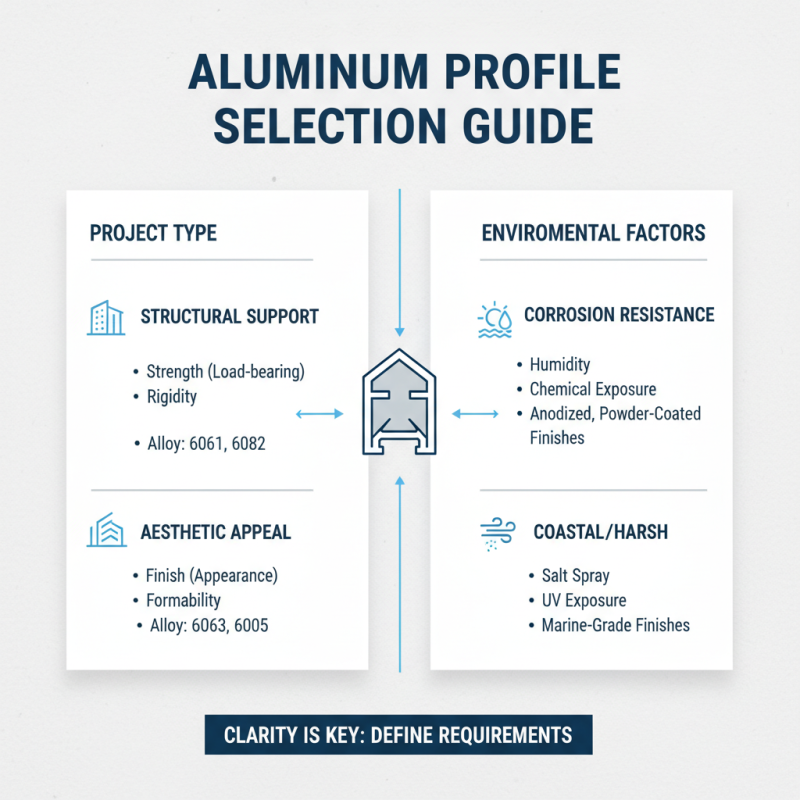

When selecting aluminum profiles, clarity is key. Understand your project's specific requirements. Are the profiles for structural support or aesthetic appeal? This distinction can change the material choice significantly. Different alloys possess varying strengths and corrosion resistance. Consider the environment they will be exposed to. For example, coastal areas require more durable finishes.

One often overlooked factor is fabrication ease. Profiles that are difficult to shape or join can lead to additional costs and delays. Lightweight profiles might seem ideal, but they may compromise strength. Look for a balance that fits your application. It’s also important to think long-term about maintenance and durability. Buying the cheapest option may seem wise, yet, cheaper materials can lead to higher replacement costs.

Don't ignore sourcing and availability. Local suppliers can offer quicker turnaround times. However, specialized profiles may only be available from specific manufacturers. Don’t get locked into a single supplier too soon. Evaluate multiple options to ensure you make an informed decision. If you're unsure, consulting with experts can also help refine your choices.

When evaluating strength and durability in aluminum profiles, several factors come into play. The alloy composition is crucial. Different alloys offer different strengths. A common choice is 6061 aluminum. It offers excellent strength and corrosion resistance. But is it always the best option? Some projects may call for a different alloy like 6063 for improved aesthetics and formability.

The thickness of the profile also matters. Thicker profiles can support heavier loads. However, they may add weight to the construction. This is a delicate balance to strike. Consider the specific application before making a decision. Additionally, surface treatment can significantly enhance durability. Options like anodizing or powder coating protect against wear and environmental exposure.

Testing for real-world conditions is another important step. How will the profile hold up under stress? Will it resist corrosion in wet environments? These questions require careful consideration. Even a minor oversight can lead to failures down the line. Working closely with a knowledgeable supplier could provide valuable insights. Yet, it's essential to ask the right questions and thoroughly evaluate all options.

When choosing aluminum construction profiles, it's crucial to weigh cost against quality. Many assume that cheaper materials will always save money. However, low-quality aluminum may lead to increased maintenance costs and shorter lifespans. A seemingly small price difference can actually result in significant long-term expenses.

It’s essential to evaluate the specific requirements of your project. Not all aluminum profiles are created equal. Some are designed for heavy loads while others are more suited for aesthetics. Not considering these factors may lead you to make hasty decisions. Are you prioritizing strength or appearance?

Quality aluminum often comes at a higher upfront cost, but its durability pays off over time. It’s a balancing act. You can save money initially, but what if it needs frequent repairs? Reflect on your long-term vision. Are you willing to compromise for short-term savings? Finding the right profile may take time, but it's worth the effort.

Aluminum profiles are increasingly popular in construction. Their sustainability is a vital consideration. According to a report by the International Aluminium Institute, aluminum can be recycled indefinitely without losing quality. This property significantly reduces the environmental impact of aluminum production. When choosing aluminum profiles, consider their lifecycle. Look for suppliers that emphasize recycling programs.

Tip: Always ask about the material's origin. Sourcing from recycled aluminum reduces carbon emissions by up to 95%. It's crucial to evaluate not just the performance of the material, but also its environmental footprint.

In addition, the energy required to produce aluminum is substantial. Yet, innovations are improving this process. Studies show that using low-carbon aluminum can cut emissions significantly. Assess the manufacturer's commitment to reducing their carbon footprint. A thoughtful choice today can lead to a more sustainable future.

Tip: Check for certifications that demonstrate environmental responsibility. This can include standards like ISO 14001. Make choices that balance performance with sustainability. Each decision impacts our environment.