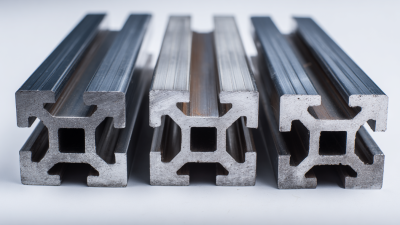

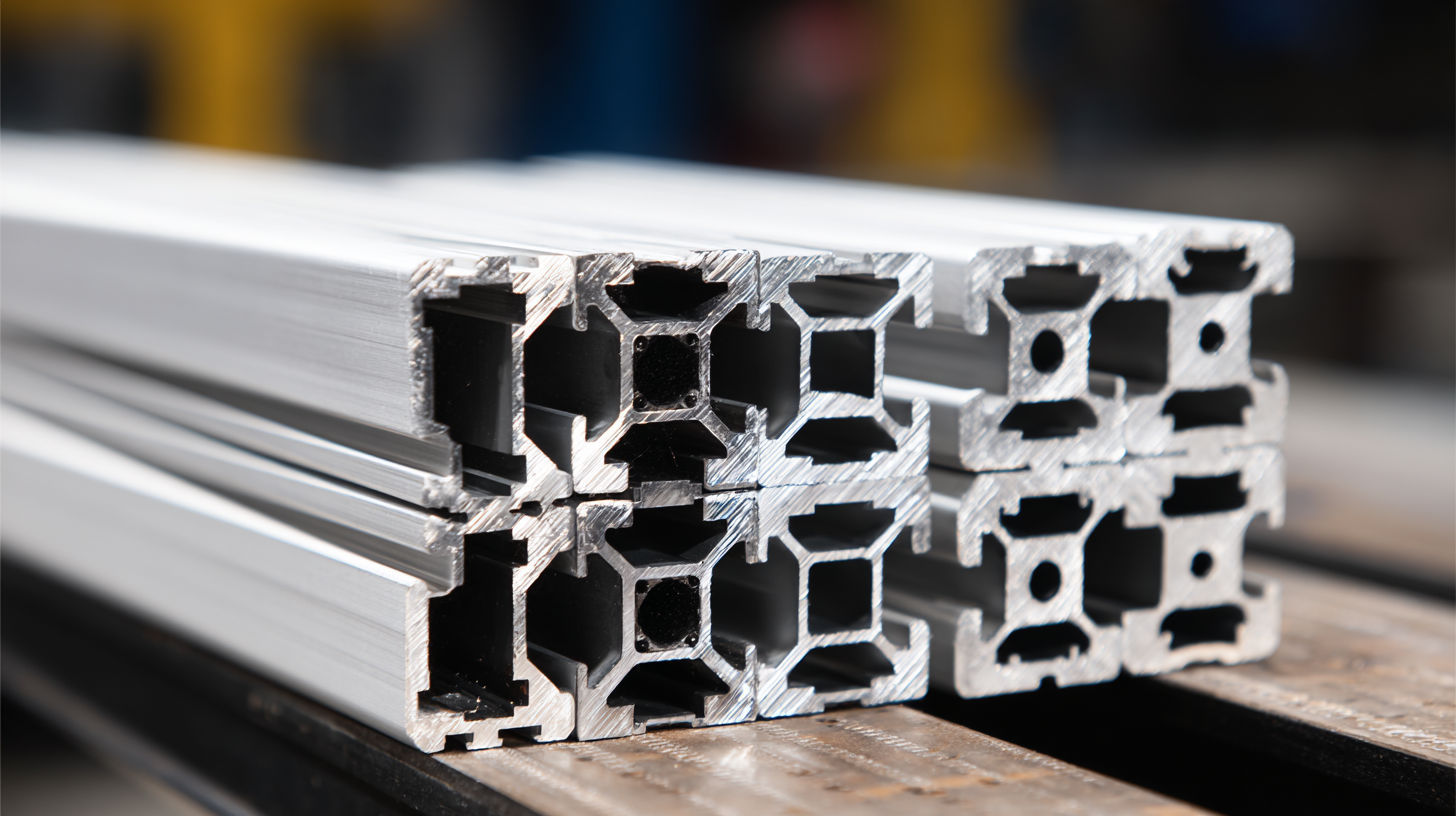

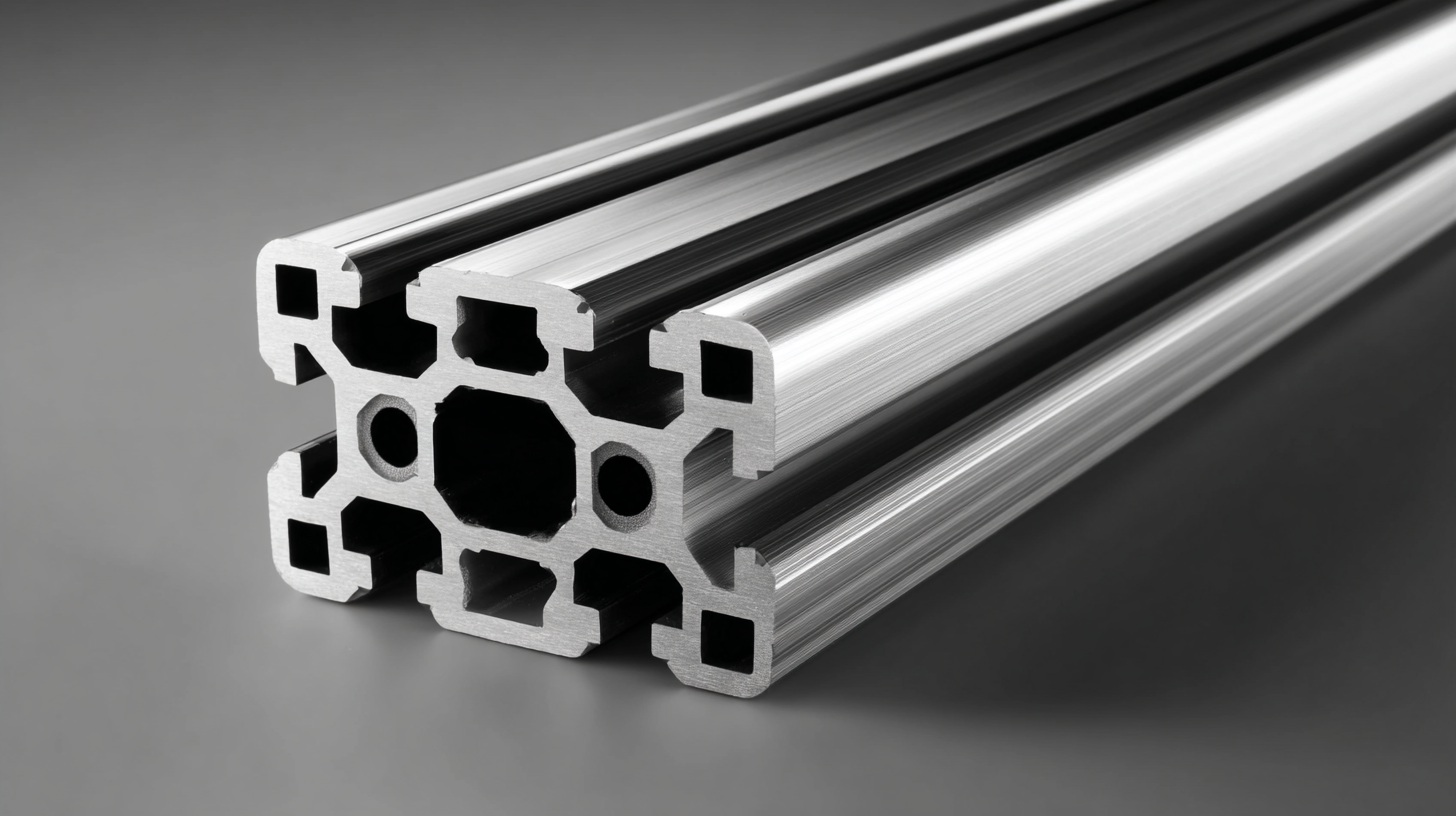

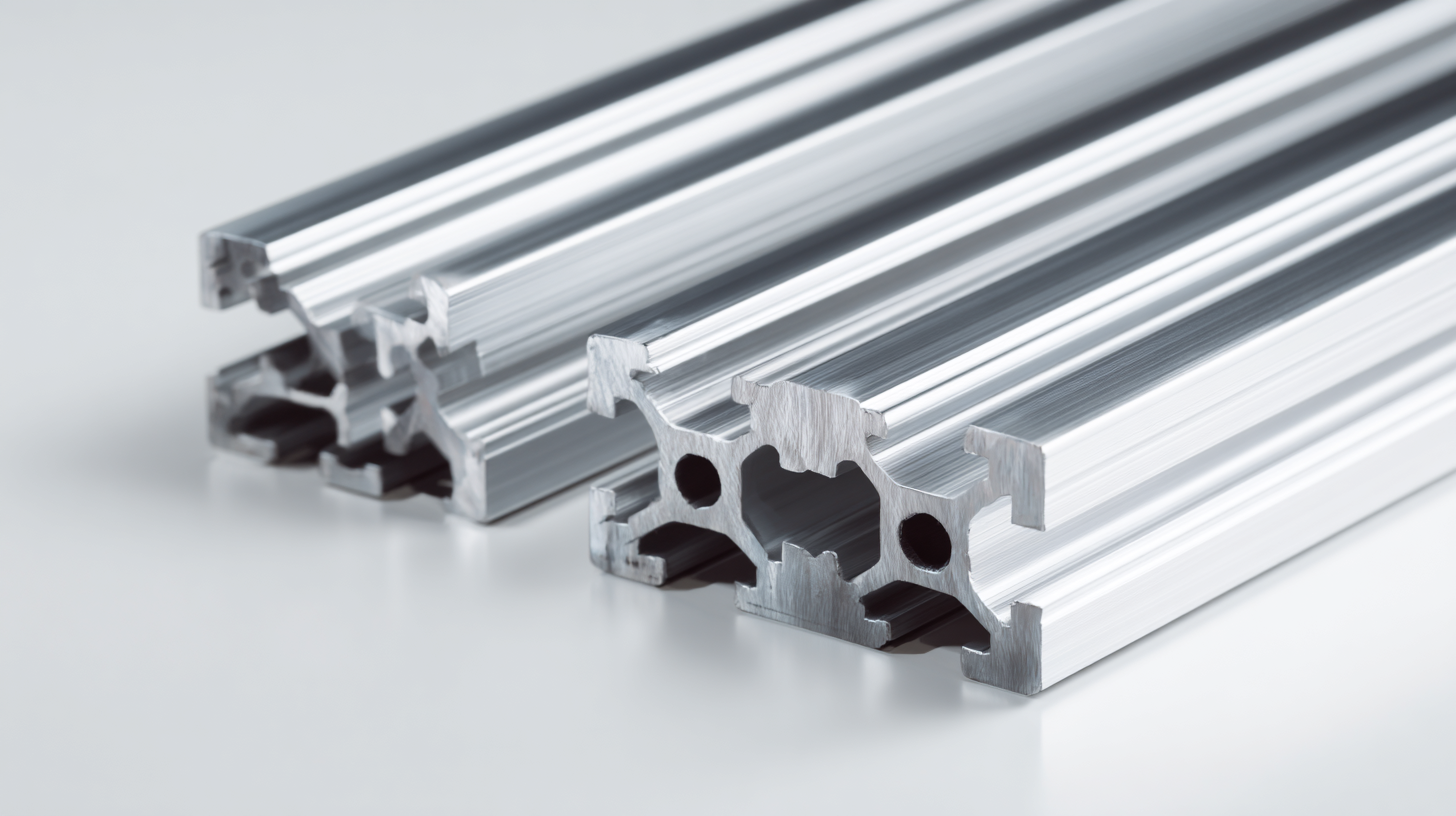

In the realm of modern manufacturing, efficiency and precision are paramount, and one of the key components driving these goals is the use of Standard Aluminum Extrusion Profiles. These profiles, characterized by their uniform cross-sectional shapes, provide a versatile foundation for a wide array of applications across different industries. By leveraging these standardized designs, manufacturers can reduce production times, minimize waste, and streamline their operations, ultimately leading to enhanced productivity and cost-effectiveness. The adaptability of Standard Aluminum Extrusion Profiles allows businesses to innovate their products while maintaining strict adherence to quality standards. As industries increasingly shift towards automation and high-speed manufacturing processes, the adoption of these profiles becomes not just beneficial, but essential for sustaining competitive advantages in a rapidly evolving marketplace.

Standard aluminum extrusion profiles play a pivotal role in reducing manufacturing costs across a variety of industries.

According to a report by the Aluminum Association, the adoption of standard profiles can reduce fabrication costs by up to 30% compared to custom designs.

This significant cost efficiency arises from decreased material waste and shorter manufacturing lead times.

By utilizing pre-designed, widely accepted profiles, manufacturers can streamline their production processes, allowing for faster turnaround times and less resource expenditure.

Tips for manufacturers:

When choosing aluminum extrusion profiles, ensure that you opt for standard sizes.

These profiles are easier to source, which can minimize supply chain disruptions and cut down on expensive custom tooling.

Additionally, leveraging these profiles can enhance your product's overall structural integrity, enabling you to deliver higher quality products with fewer defects.

As industries continue to lean toward sustainability, standard aluminum extrusion profiles also provide an eco-friendly advantage.

According to a study from the American Council for an Energy-Efficient Economy, using standardized materials can lead to a 25% reduction in energy consumption during manufacturing.

Incorporating these profiles not only helps in slashing costs but supports greener manufacturing practices, aligning with global sustainability goals.

Standard aluminum extrusion profiles play a crucial role in enhancing the efficiency of modern manufacturing processes. One key benefit of utilizing these profiles is their ability to simplify design and production workflows. By using standardized shapes and sizes, manufacturers can significantly reduce design time, enabling quicker transitions from concept to production. This efficiency translates into shorter lead times, allowing businesses to respond more rapidly to market demands and customer needs.

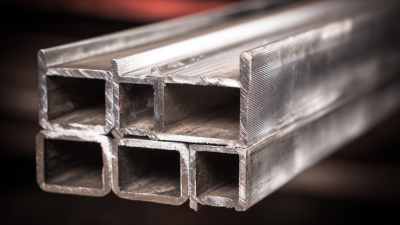

Moreover, standard aluminum profiles contribute to consistent quality and interoperability in manufacturing. When using uniform components, assembly processes become more streamlined, minimizing errors and the need for adjustments. Additionally, these profiles are easily accessible from multiple suppliers, ensuring that manufacturers can source materials reliably and cost-effectively. This availability not only lowers procurement costs but also enhances supply chain resilience. As a result, adopting standard aluminum extrusion profiles becomes a strategic choice for companies aiming to optimize their production processes and maintain a competitive edge in today's fast-paced industrial landscape.

Standardized aluminum extrusion profiles play a pivotal role in enhancing supply chain efficiency and reducing lead times in modern manufacturing. By utilizing standardized profiles, manufacturers can streamline their production processes, allowing for quicker responses to market demands. This efficiency is further underscored by recent trends in sustainable manufacturing, where advancements in material extrusion and additive manufacturing are reshaping traditional paradigms. With the convergence of innovative production technologies, companies can achieve greater performance and sustainability, ultimately driving down costs and delivery times.

Moreover, the integration of lean management principles with additive manufacturing techniques presents significant opportunities for improving resource efficiency. By minimizing waste and optimizing workflows, manufacturers can leverage standardized aluminum extrusions to build more resilient supply chains. As the industry evolves, these extrusions will not only enhance production capabilities but also support environmental goals, thereby reflecting a broader commitment to sustainable practices in manufacturing.

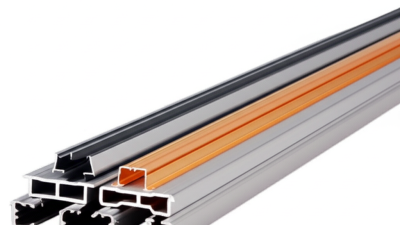

Standard aluminum extrusion profiles have emerged as game-changers in various manufacturing sectors, driving enhanced productivity and operational efficiency. In the automotive industry, for example, companies have embraced these profiles for their lightweight properties, which not only improve fuel efficiency but also simplify assembly processes. By utilizing standard profiles, manufacturers can reduce lead times, as the components are readily available and compatible with existing systems, facilitating faster assembly and reducing downtime.

Another notable case is the construction industry, where standard aluminum profiles are pivotal in the creation of modular designs. The use of these profiles allows for quicker installation and adaptability to different architectural needs, streamlining the entire building process. Companies report that implementing standard profiles leads to a significant decrease in construction time and labor costs, demonstrating how standardization can result in measurable efficiencies across the board. These examples underscore the vital role that standard aluminum extrusion profiles play in optimizing productivity in diverse manufacturing environments.

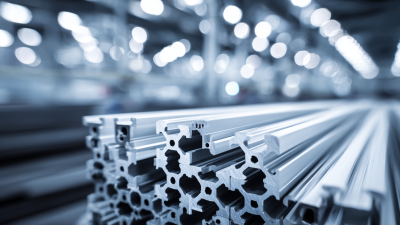

In recent years, the adoption rates of standard aluminum extrusions in modern manufacturing practices have surged, driven by the need for efficiency and versatility. Manufacturers are increasingly recognizing the advantages of using standardized profiles, which not only streamline production processes but also reduce lead times. This shift enables companies to respond to market demands quickly and effectively, accommodating rapid changes in design specifications or scaling production up or down as needed.

Moreover, the trend toward sustainability is influencing the adoption of aluminum extrusions. As industries seek to minimize their environmental impact, aluminum's recyclability and lighter weight compared to other materials make it an attractive option. With the rise of automation and smart manufacturing techniques, standardized aluminum profiles provide a reliable solution that helps integrate new technologies seamlessly into existing workflows. As a result, this growing trend signifies a crucial evolution in manufacturing, emphasizing the importance of adaptability and resource efficiency in a competitive landscape.