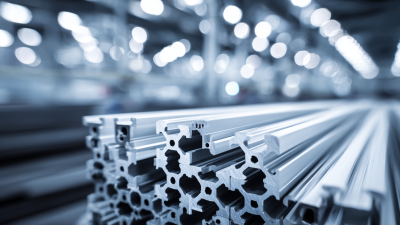

In today's competitive manufacturing landscape, mastering the art of sourcing Channel Aluminum Extrusion Profiles is crucial for businesses aiming to enhance their product offerings and streamline their operations. According to a recent report by Grand View Research, the global aluminum extrusion market is projected to reach $82.66 billion by 2026, growing at a CAGR of 5.0%. This growth underscores the increasing demand for versatile and lightweight materials across various industries, including automotive, construction, and electronics. As companies strive to optimize their supply chains and maintain cost-efficiency, understanding the sourcing strategies specific to Channel Aluminum Extrusion Profiles becomes essential.

In this blog, we will explore practical tips and insights that will help you navigate the complexities of sourcing these profiles effectively, ensuring that your business remains competitive and responsive to market demands.

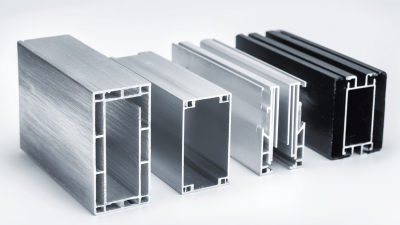

Channel aluminum extrusion profiles are becoming increasingly popular across various industries due to their

versatility and strength. These profiles offer numerous benefits,

making them essential in applications ranging from construction to manufacturing and automotive sectors. The

lightweight nature of aluminum, combined with its corrosion resistance, ensures that

channel extrusions endure harsh environments while maintaining structural integrity. Additionally, they can be easily

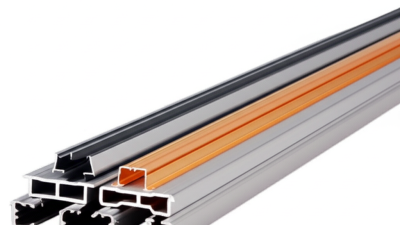

customized to meet specific design requirements, allowing businesses to optimize their projects efficiently.

Channel aluminum extrusion profiles are becoming increasingly popular across various industries due to their

versatility and strength. These profiles offer numerous benefits,

making them essential in applications ranging from construction to manufacturing and automotive sectors. The

lightweight nature of aluminum, combined with its corrosion resistance, ensures that

channel extrusions endure harsh environments while maintaining structural integrity. Additionally, they can be easily

customized to meet specific design requirements, allowing businesses to optimize their projects efficiently.

When sourcing channel aluminum extrusion profiles, consider the following tips for a successful procurement process. First, assess the intended application and required specifications to determine the profile dimensions and thickness. This clarity helps in selecting the right manufacturer that can provide quality extrusions tailored to your needs. Next, establish a strong relationship with suppliers to benefit from their expertise and insights, ensuring you stay updated on industry trends and innovations. Finally, don’t hesitate to request samples to evaluate the product's quality before committing to larger orders.

As industries continue to evolve, the significance of efficient materials like channel aluminum extrusion profiles will grow. Investing time in understanding their features and sourcing them effectively will lead to enhanced performance and cost-savings for your projects.

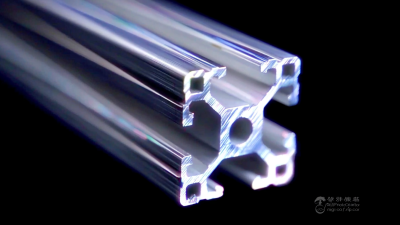

When evaluating material alternatives for channel extrusion profiles, it's essential to understand the strengths and weaknesses of each option. Channel aluminum is often favored for its lightweight nature, corrosion resistance, and excellent thermal conductivity. These properties make aluminum extrusions ideal for various applications, particularly in industries where weight reduction and durability are paramount. In addition, aluminum's malleability allows for intricate designs that are both functional and aesthetically pleasing, an advantage over more rigid materials.

On the other hand, steel extrusions provide superior strength and rigidity, making them suitable for heavy-duty applications. However, they come with the downside of being significantly heavier and more prone to corrosion unless they are properly treated. Plastic extrusions, while lightweight and resistant to various chemicals, may lack the structural integrity needed for demanding applications. Therefore, the choice between channel aluminum, steel, and plastic profiles ultimately hinges on the specific requirements of a project, including weight, strength, and environmental factors. Understanding these nuances can guide businesses in making informed decisions that align with their operational goals.

When considering the procurement of channel aluminum extrusion profiles, cost-effectiveness becomes a pivotal factor in ensuring long-term savings for your business. The initial investment in sourcing high-quality aluminum profiles may seem substantial, but when analyzed through the lens of durability and performance, the long-term benefits often outweigh these costs. Selecting reputable suppliers who provide superior products can reduce maintenance and replacement expenses, leading to significant financial advantages over time.

Furthermore, a thorough cost-effectiveness analysis involves evaluating not only the price per unit but also the total cost of ownership. This includes factors such as transportation expenses, potential waste during fabrication, and the energy efficiency of the final product. By calculating these variables, businesses can make informed decisions that align with their financial goals.

Investing in high-grade aluminum profiles may necessitate a larger upfront expenditure, but the assurance of longevity and reduced operational costs translates into a sustainable financial strategy, ensuring your investment pays off well into the future.

In the competitive landscape of channel aluminum extrusion manufacturing, maintaining high-quality standards is paramount. According to a recent report by the Aluminum Association, nearly 30% of manufacturing defects can be traced back to inadequate quality control measures during the extrusion process. Implementing robust quality control metrics can significantly mitigate these issues, enhancing product reliability and customer satisfaction.

Key quality metrics include dimensional accuracy, surface finish, and mechanical properties, which must be systematically evaluated at every stage of production. The American Society for Testing and Materials (ASTM) specifies rigorous testing procedures that include tensile tests and visual inspections to ensure that extruded profiles meet defined specifications. By adhering to these standards, manufacturers can not only uphold product quality but also reduce costs associated with rework and returns.

Investing in comprehensive quality control processes can lead to a remarkable increase in product consistency, enabling businesses to better compete in the market and meet customer demands efficiently.

When it comes to sourcing materials for manufacturing, the environmental impact cannot be overlooked. Channel aluminum extrusion profiles present a sustainable option compared to other materials like steel or plastic. Aluminum is highly recyclable, with the ability to retain its properties no matter how many times it is processed. This characteristic not only reduces the demand for new raw materials but also minimizes energy consumption associated with material extraction and production.

In contrast, producing steel often involves mining and significant energy use, contributing to a higher carbon footprint. Furthermore, the lifecycle of plastic materials tends to be less favorable due to their persistence in landfills and the challenges associated with recycling. By choosing channel aluminum profiles, businesses can align themselves with sustainability goals while benefiting from the lightweight and strong nature of aluminum, which enhances fuel efficiency in transportation and reduces overall operational costs. The environmental benefit of channel aluminum is clear, making it an ideal choice for conscientious manufacturers looking to make a positive impact.