The market for Aluminum Extrusion Tube Profiles is projected to witness significant growth by 2025, driven by the increasing demand across various industries including automotive, aerospace, and construction. According to a recent industry analysis, the aluminum extrusion market is expected to reach approximately $80 billion, with tube profiles playing a pivotal role due to their lightweight, durability, and versatility. As companies prioritize both sustainability and cost-effectiveness, the adoption of Aluminum Extrusion Tube Profiles is on the rise, offering advantages such as design flexibility and improved performance.

This blog will explore the key features that set apart the best aluminum extrusion tube profiles, incorporating insights drawn from comprehensive market reports and expert recommendations to guide manufacturers and designers in selecting optimal solutions for their needs.

Aluminum extrusion tube profiles are increasingly favored in modern industries due to their numerous advantages. One of the key benefits is their lightweight nature, which significantly reduces transportation costs and enhances fuel efficiency in applications like automotive and aerospace. Unlike traditional materials, aluminum offers a superior strength-to-weight ratio, allowing manufacturers to create robust structures without adding unnecessary bulk. This characteristic makes aluminum extrusion an ideal choice for companies seeking to improve their product performance without compromising on weight.

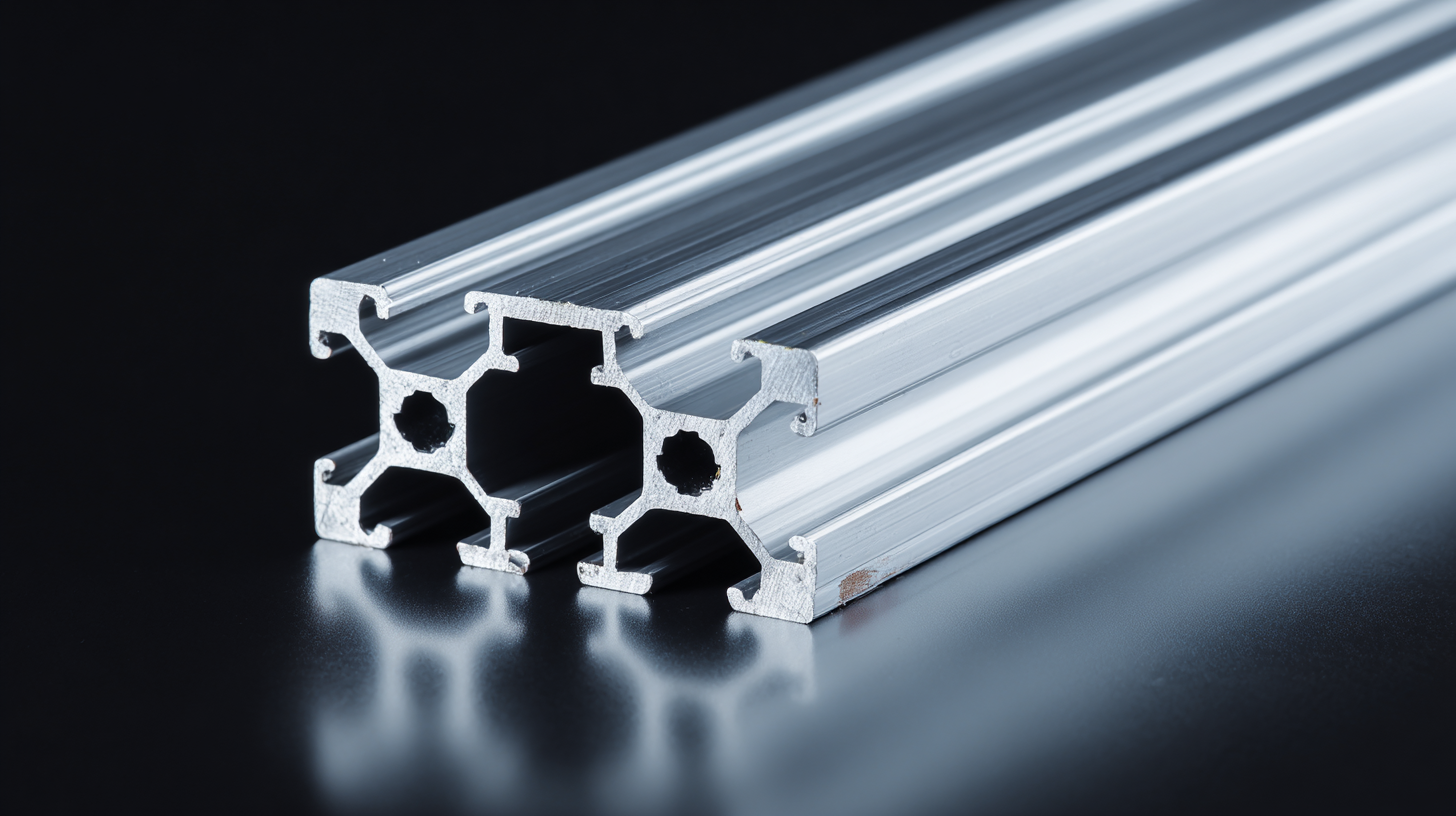

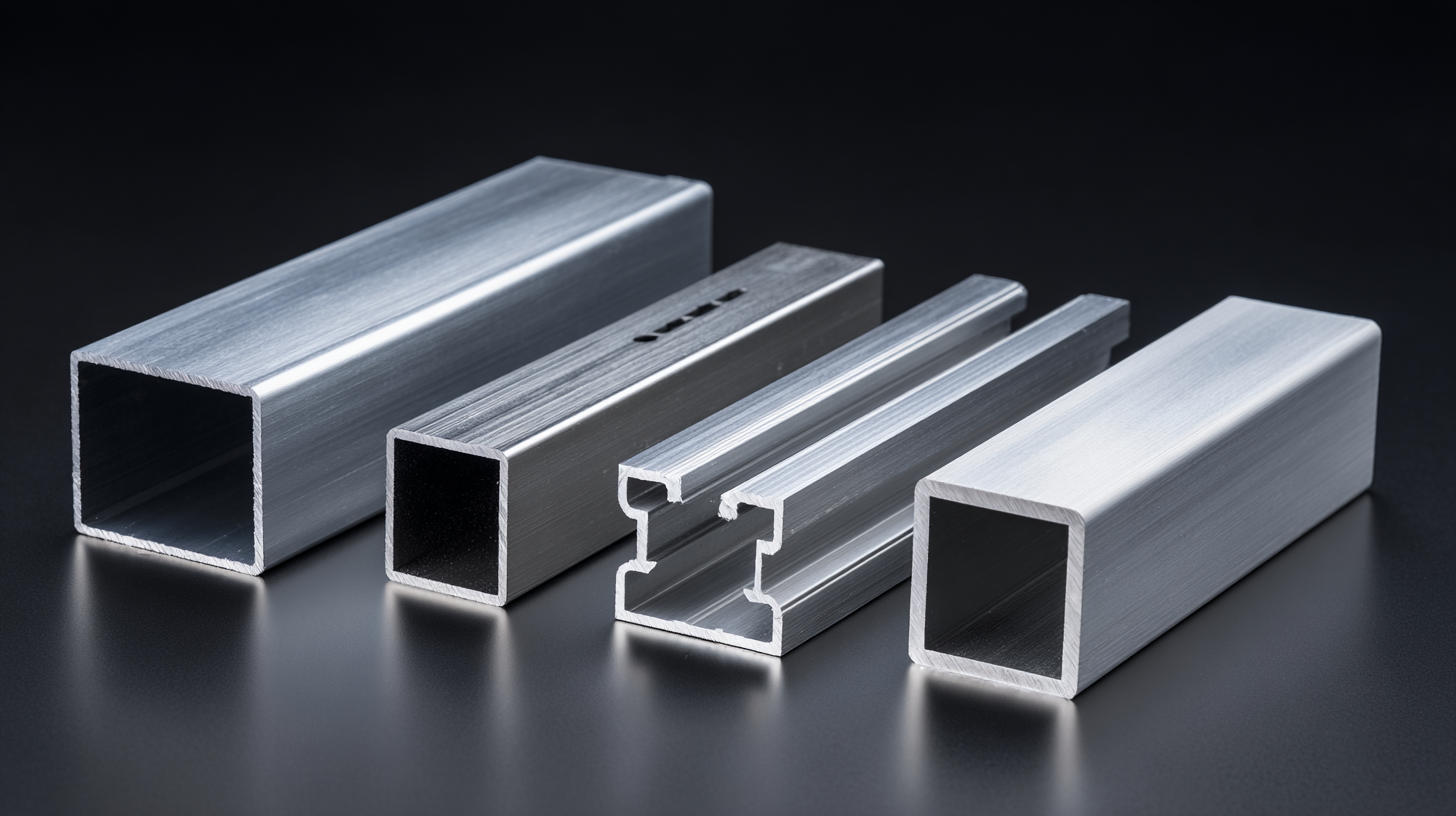

Another significant advantage of aluminum extrusion tube profiles is their versatility. Available in various sizes, shapes, and finishes, these profiles can be customized to meet the specific needs of different industries. This adaptability is particularly beneficial in sectors like construction, where tailored solutions can be developed for architectural elements, framing systems, or even intricate designs. Additionally, the corrosion resistance of aluminum mitigates maintenance costs and extends the lifespan of products crafted from these materials, making them a cost-effective solution in the long run. With sustainability becoming a focal point in manufacturing, aluminum's recyclability further enhances its appeal, enabling industries to align with eco-friendly practices while benefiting from high-quality materials.

When considering the design of aluminum extrusion tube profiles, innovation is key to achieving optimal performance and aesthetic appeal. Designers should focus on the intended application of the aluminum tube, such as structural support or functional enclosures. Incorporating features like lightweight strength, corrosion resistance, and thermal conductivity can enhance functionality while ensuring longevity.

When considering the design of aluminum extrusion tube profiles, innovation is key to achieving optimal performance and aesthetic appeal. Designers should focus on the intended application of the aluminum tube, such as structural support or functional enclosures. Incorporating features like lightweight strength, corrosion resistance, and thermal conductivity can enhance functionality while ensuring longevity.

Tips: Begin with a clear understanding of the application requirements. This will guide the selection of appropriate alloy choices and profile shapes. Consider using software tools for simulation and modeling to visualize how different designs will perform under stress and environmental conditions.

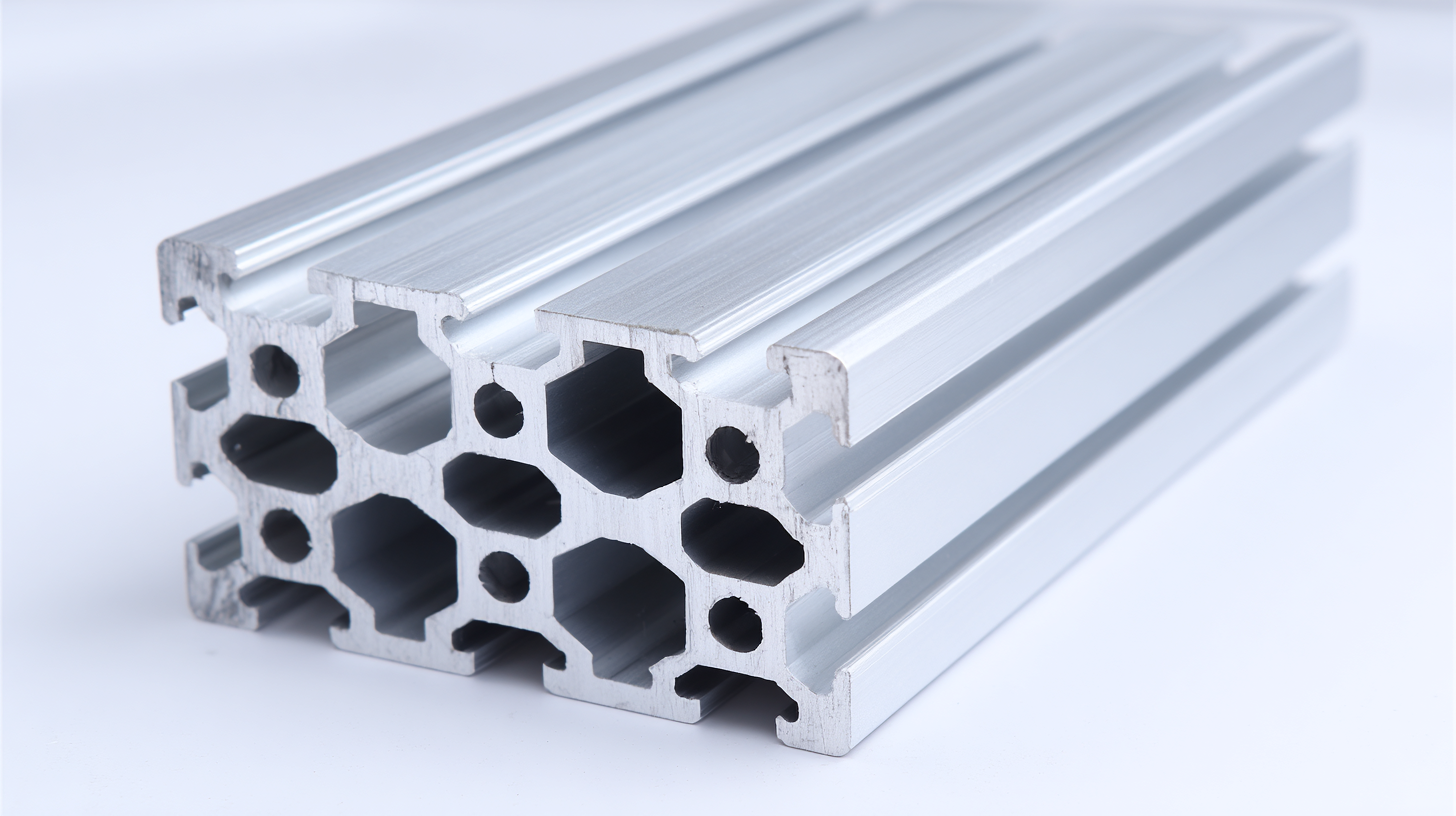

Moreover, precision in the extrusion process cannot be overlooked. Factors like die design, temperature control, and extrusion speed all play a vital role in the outcome of the profiles. Employing advanced manufacturing techniques such as 3D printing for prototypes can help refine designs before full-scale production.

Tips: Collaborate with manufacturers who have expertise in aluminum extrusion to leverage their knowledge and capabilities. Constantly seek feedback during the design phase to align with industry standards and customer expectations, ensuring that the final product is both innovative and practical.

Sustainability is rapidly becoming a crucial consideration in the aluminum extrusion industry, driven by global trends towards greener manufacturing practices. According to a report from the International Aluminum Institute, the recycling rate of aluminum can reach up to 75%, making it one of the most sustainable materials available. This high recyclability not only reduces the environmental impact of aluminum production but also supports a circular economy, where materials are reused, minimizing waste. As companies adopt more sustainable practices, the demand for aluminum extrusion tubes manufactured from recycled materials is steadily increasing.

Recent advancements in aluminum extrusion technology emphasize energy efficiency and environmentally friendly processes. A study from the Aluminum Extruders Council indicates that modern extrusion techniques can reduce energy consumption by up to 30% compared to traditional methods. Additionally, innovative designs and automated systems are enabling manufacturers to produce lightweight yet strong profiles that cater to various applications, from automotive to construction. By embracing these sustainable trends, the aluminum extrusion industry is not only enhancing its competitiveness but also contributing to global efforts in reducing carbon footprints and fostering sustainable development.

When it comes to the production of high-quality aluminum extrusion tube profiles, essential manufacturing techniques play a pivotal role. The aluminum extrusion process involves heating aluminum billets until they become malleable, allowing them to be forced through a die to create specific shapes. According to a report from the Aluminum Association, approximately 80% of aluminum produced in the U.S. is used in extrusion applications, highlighting the significance of this method in various industries, from automotive to construction.

One critical technique is precision die design, which is vital for ensuring dimensional accuracy and surface quality. A study by Smithers Pira found that advancements in die technology can improve production efficiency by up to 30%. Additionally, the implementation of strict quality control measures—such as ultrasonic testing and dimensional inspection—ensures that the finished profiles meet industry standards. The global aluminum extrusion market is projected to reach $71 billion by 2027, driven by the rising demand for lightweight materials in sustainable manufacturing. Thus, mastering these essential techniques not only enhances product quality but also secures a competitive edge in the thriving aluminum extrusion industry.

The future of aluminum extrusion innovations is bright, with advancements poised to reshape the industry. According to a report by Research and Markets, the global aluminum extrusion market is expected to reach $67.12 billion by 2028, growing at a CAGR of 5.4% from 2021 to 2028. This growth is driven by the rising demand for lightweight materials in the automotive, aerospace, and construction sectors, where aluminum's strength-to-weight ratio offers significant advantages. Innovative techniques such as thermal break technology and improved die design are making it possible to produce more complex and high-performance profiles, catering to the specific needs of various industries.

Moreover, sustainability is becoming a key focus within the aluminum extrusion sector. The Aluminum Association reports that approximately 75% of all aluminum ever produced is still in use today, highlighting its recyclability. As manufacturers strive to meet increasing regulations on carbon emissions, many are investing in greener extrusion processes and sustainable sourcing of raw materials. Technologies like closed-loop recycling and energy-efficient production methods not only reduce waste but also lower operational costs, driving competitiveness in an evolving market. As these innovations unfold, they are set to provide significant opportunities for growth and differentiation in the aluminum extrusion industry.

| Feature | Description | Advancement Type |

|---|---|---|

| Lightweight | Aluminum extrusion tubes are significantly lighter than steel or other materials, making them ideal for applications where weight is a concern. | Material Innovation |

| Corrosion Resistance | These tubes have excellent resistance to corrosion, especially when treated, which extends their lifespan in various environments. | Surface Treatment Techniques |

| Versatility | Aluminum extrusion can be shaped into a variety of profiles to meet the specific needs of different industries. | Design Adaptations |

| Sustainability | Aluminum is recyclable, and advancements in the extrusion process are making it more environmentally friendly. | Sustainable Practices |

| Enhanced Strength | Advanced extrusion techniques have improved the strength-to-weight ratio of aluminum tubes. | Engineering Innovations |

| Cost-Effectiveness | Efficient production processes lower costs while maintaining high quality standards. | Production Efficiency |