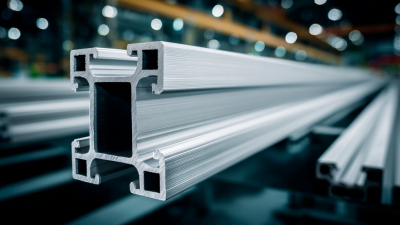

In the ever-evolving world of construction, the pursuit of efficiency and sustainability has led to the emergence of innovative solutions, particularly in the use of Aluminum Profiles. These versatile materials are not only lightweight and strong but also possess a unique ability to enhance energy efficiency in building designs. By integrating advanced technology and design principles, Aluminum Profiles are being transformed into essential components that reduce waste, lower carbon footprints, and improve overall structural performance. This blog delves into the reasons why Aluminum Profiles are becoming increasingly favored in modern construction, shedding light on their role in promoting sustainable practices while optimizing project timelines and costs. Join us as we explore the innovative advancements that make Aluminum Profiles a key player in the future of the construction industry.

The aluminum profile manufacturing industry plays a crucial role in construction, yet it faces common challenges such as resource optimization and sustainability. Innovative approaches are essential to address these issues effectively. By integrating advanced technologies and sustainable practices, manufacturers can enhance production efficiency while reducing environmental impacts.

Recent research highlights the importance of adopting eco-friendly processes in aluminum production. Techniques like closed-loop recycling and energy-efficient smelting not only lower emissions but also conserve resources. Furthermore, the utilization of smart manufacturing systems can streamline operations, minimizing waste and improving material yields. As the demand for sustainable construction solutions rises, embracing these innovative strategies will be key for the aluminum industry to thrive and contribute positively to the economy.

Incorporating these innovative approaches not only helps overcome existing challenges but also positions the industry as a leader in sustainable development. By focusing on efficiency and environmental responsibility, aluminum profile manufacturers can meet the increasing demands of the construction sector while supporting economic growth and job creation.

The construction industry has long faced challenges related to waste and sustainability, particularly when it comes to materials like aluminum profiles. Adopting sustainable practices is essential for reducing waste in aluminum profile construction. One innovative approach involves the use of advanced manufacturing techniques that minimize excess material. By implementing precision cutting and optimized design algorithms, builders can ensure that every piece of aluminum is utilized effectively, thereby reducing scrap and lowering costs.

Moreover, the incorporation of recycled aluminum into new profiles is a game-changer. Utilizing recycled materials not only diminishes the environmental impact associated with mining and processing raw aluminum but also helps maintain the materials' strength and durability. Architects and builders can create structures that are not only aesthetically pleasing but also aligned with sustainability goals, promoting a circular economy within the construction sector. As industry leaders continue to explore these practices, the benefits extend beyond waste reduction; they enhance overall efficiency and contribute to a greener future for construction.

As the construction industry increasingly focuses on

energy efficiency and

sustainability, advanced aluminum profile solutions are at the forefront of this transformation. These innovative materials not only offer structural benefits but also significantly enhance the overall thermal performance of buildings.

According to the Aluminum Association, using high-quality aluminum profiles can improve energy efficiency by up to 30%, which is critical considering that buildings account for approximately 40% of global energy consumption.

One of the key advantages of aluminum profiles is their lightweight nature, which reduces the overall load on structures while maintaining strength. This property not only facilitates easier handling and installation but also contributes to reduced transportation emissions.

Experts from the International Aluminium Institute stated that adopting aluminum in construction could lead to a 10% reduction in the carbon footprint of building materials. Therefore, architects and builders are encouraged to incorporate aluminum profiles to meet both energy efficiency and sustainability goals.

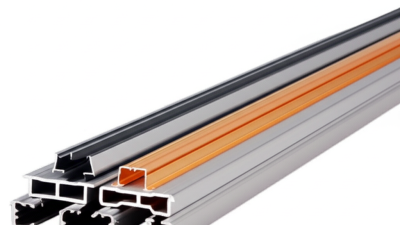

In recent years, technological innovations have significantly transformed the use of aluminum profiles in modern construction. With the rise of advanced manufacturing techniques, including 3D printing and automated fabrication, the efficiency and precision of aluminum components have reached unprecedented levels. These innovations not only streamline the assembly process but also reduce material waste, enhancing sustainability in construction. By utilizing digital design tools, architects and engineers can create complex, customized profiles that meet specific project requirements while ensuring optimal structural performance.

Moreover, innovations in surface treatments and coatings are enhancing the longevity and resilience of aluminum profiles, making them suitable for a variety of environments. These advanced finishes offer improved resistance to corrosion and wear, ensuring that aluminum structures maintain their aesthetic and structural integrity over time. As the construction industry increasingly prioritizes sustainability, the lightweight nature of aluminum combined with these technological advancements positions it as a frontrunner in eco-friendly building solutions. With ongoing research and development, the future of aluminum profiles in construction appears brighter than ever, aligning with the industry's goals for efficiency and sustainability.

| Dimension | Value | Impact on Construction |

|---|---|---|

| Weight Reduction | 30% | Lower transportation costs and ease of handling. |

| Energy Efficiency | 20% decrease in energy consumption | Improved thermal performance in buildings. |

| Recycled Content | 75% | Reduces environmental footprint and conserves resources. |

| Durability | Up to 50 years lifespan | Lower maintenance costs and prolonged use in constructions. |

| Modular Design | Flexible components | Reduced waste and efficiency in assembly. |

The future of aluminum profiles in construction is closely intertwined with trends in efficiency and sustainability. As the demand for environment-friendly building materials rises, aluminum profiles stand out due to their lightweight characteristics and recyclability. Recent advancements in manufacturing techniques are enhancing the material's performance while minimizing energy consumption during production. Innovative processes are being developed that not only reduce waste but also lower the carbon footprint associated with traditional construction methods.

Tip: Consider choosing aluminum profiles that are sourced from recycled materials, as this reduces the environmental impact and supports a circular economy in construction.

Furthermore, the integration of aluminum profiles with energy-efficient technologies can significantly improve overall building performance. By incorporating insulated aluminum elements that bolster thermal efficiency, structures can achieve better energy conservation. The emphasis on energy-efficient practices is evident, with new manufacturing innovations focusing on reducing energy demands without compromising quality or durability.

Tip: Regularly assess your construction projects for opportunities to incorporate energy-efficient aluminum profiles to enhance sustainability and reduce long-term operational costs.