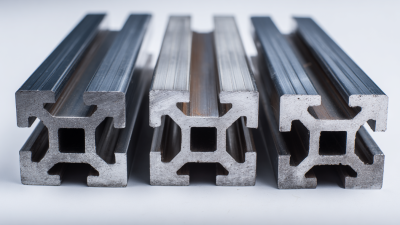

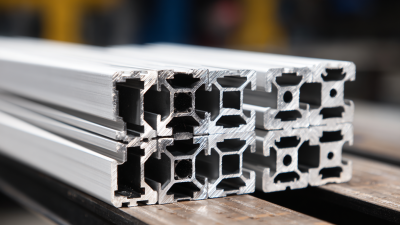

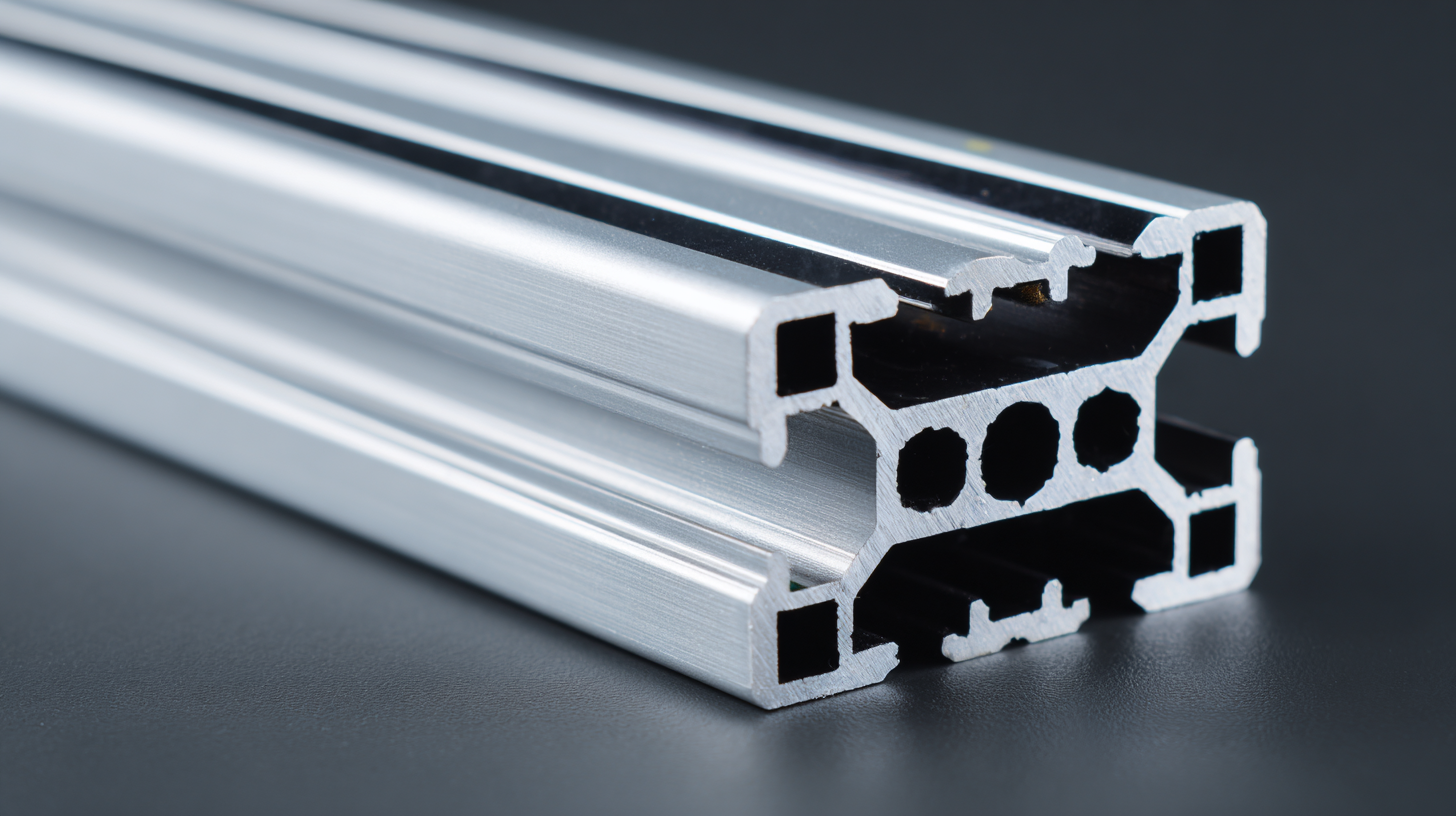

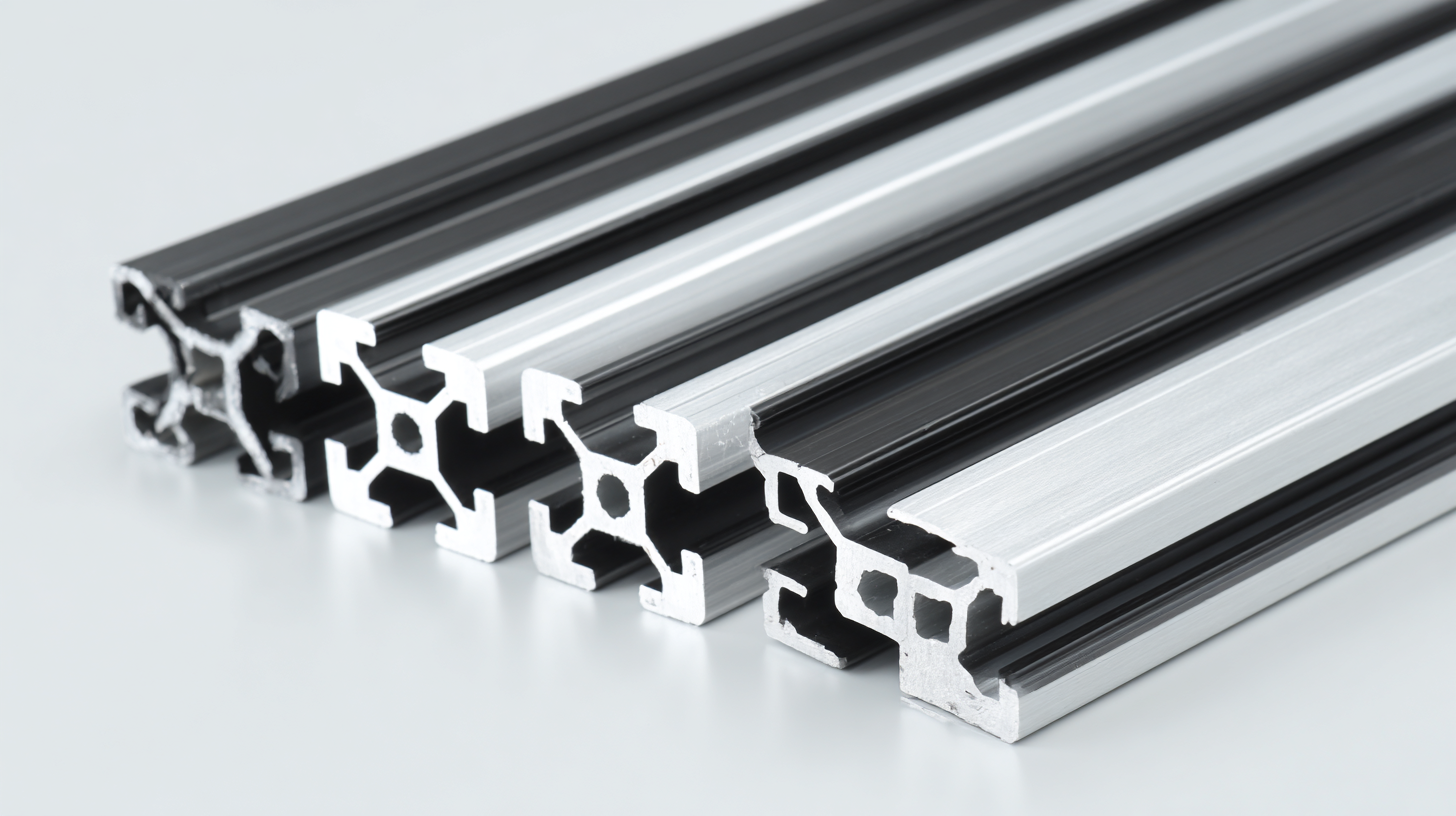

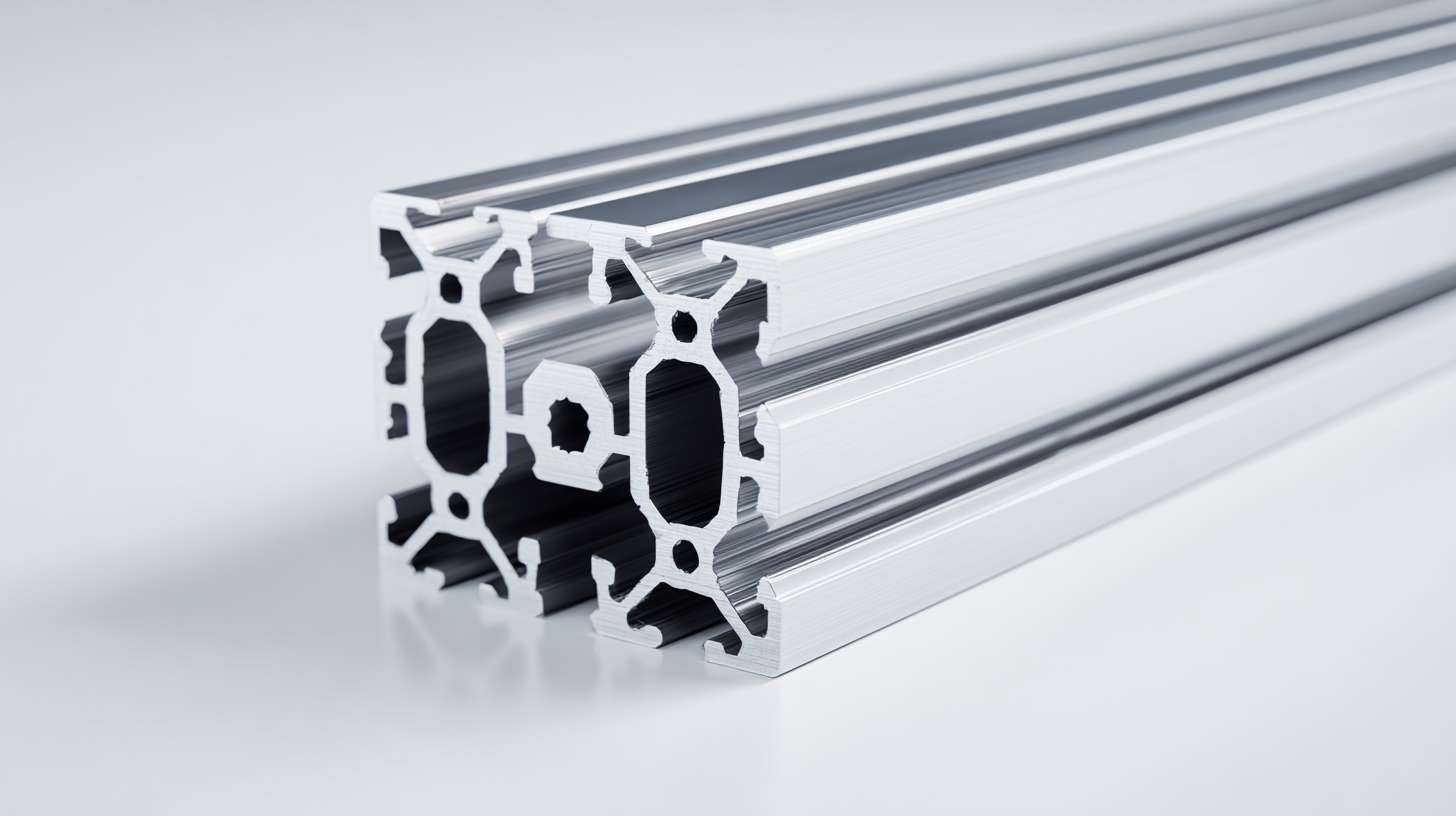

The emergence of T Slot Aluminum Extrusion Profiles has revolutionized modern design, offering an unparalleled level of versatility and adaptability across various industries. These innovative profiles, characterized by their modular nature, provide designers and engineers with the flexibility to create everything from intricate frameworks to robust assemblies. The unique slot design facilitates easy connectivity and customization, enabling rapid prototyping and iterative development processes. As industries increasingly seek to streamline production and enhance aesthetic appeal, T Slot Aluminum Extrusion Profiles are becoming an essential element in diverse applications such as furniture design, automation equipment, and workstation layouts. This article explores the multifaceted uses of these profiles, highlighting their significance in driving innovation and efficiency in contemporary design practices.

The rise of T slot aluminum extrusions in modern architecture reflects a growing trend toward versatility and adaptability in design. These profiles are not only functional but also contribute to the aesthetics of spaces, melding seamlessly into different architectural styles, including the striking features of brutalist design. The ability of T slot aluminum to accommodate various configurations allows architects to experiment with both bold and minimalist designs, emphasizing their innovative use in contemporary structures.

Tips for incorporating T slot aluminum extrusions into your design projects include selecting profiles that match the overall aesthetic of your architecture while considering structural requirements. Additionally, experimenting with different finishes can enhance visual appeal and functionality. For smaller spaces, consider using these extrusions in multifunctional furniture designs that can be both space-saving and stylish, embodying the essence of modern living.

As the demand for efficient storage solutions and flexible layouts increases, T slot aluminum extrusions offer creative possibilities for organizing spaces, especially in open-concept kitchens. By utilizing these profiles, designers can create customized shelving and organizational systems that maintain clean lines and an uncluttered look, embracing the principles of modern architecture while promoting practicality and innovation.

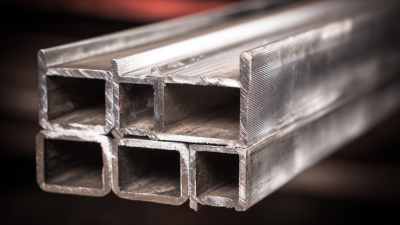

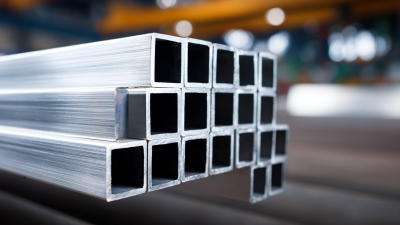

T-slot aluminum extrusion profiles are increasingly recognized for their cost efficiency in modern manufacturing. These systems not only reduce material waste but also streamline the assembly process, saving both time and labor costs. By enabling modular design, T-slot profiles allow manufacturers to create versatile structures without the need for complex welding or machining. This flexibility translates to significant savings in both production and operational expenses.

Recent industry data highlights the financial benefits of T-slot systems. Companies that have integrated these profiles report up to 30% reductions in material costs due to their efficient use of aluminum and the ability to repurpose components for various applications. Moreover, shorter lead times and quicker assembly translate to lower overall project costs, making T-slot systems an attractive option for businesses aiming to optimize their resources while maintaining a high level of design versatility. This innovative approach to manufacturing not only enhances productivity but also aligns with sustainability goals by minimizing waste and promoting reuse.

T-slot aluminum extrusion profiles have revolutionized the way we approach furniture design and modular solutions. With their inherent versatility, these profiles allow designers to create custom configurations that cater to various needs. According to a report by the Aluminum Association, the market for aluminum extrusion is expected to reach $35 billion by 2025, highlighting the increasing adoption of these profiles across multiple industries, including furniture.

One compelling case study involves the use of T-slot profiles in workstation design. A leading office furniture manufacturer implemented a modular desk system that allows users to reconfigure their workspace effortlessly. This approach not only enhances functionality but also promotes collaboration in increasingly dynamic work environments. The ability to adapt to changing needs is a significant advantage, as revealed by a survey from the International Furniture and Design Association, which found that 78% of companies prioritize flexible furniture solutions.

**Tip:** When designing with T-slot profiles, always consider modularity. Different configurations can drastically improve space utilization, allowing for future adjustments without substantial costs.

Another example of innovation is seen in home furniture applications. A prominent contemporary furniture brand utilized T-slot aluminum in its modular shelving units, providing customers with the freedom to customize their layouts. The durability and lightweight properties of aluminum make these designs not only practical but also aesthetically pleasing. According to a study by Market Research Future, products utilizing aluminum extrusions are gaining preference in residential applications, with an anticipated growth rate of over 6% annually.

**Tip:** Leverage the lightweight nature of T-slot aluminum for easy assembly and disassembly, enabling consumers to rearrange their spaces with minimal effort.

As the demand for sustainable design solutions grows, aluminum extrusion profiles are emerging as a key player in eco-friendly construction practices. With their lightweight properties and high durability, aluminum extrusions can significantly reduce the energy consumption of buildings throughout their lifecycle. This versatility makes them ideal for various applications, ranging from structural components to aesthetic finishes.

Moreover, companies are increasingly investing in low-carbon aluminum production methods, which further enhance their sustainability credentials. Innovations, like custom-designed aluminum profiles, allow for high-performance solutions that not only meet design requirements but also contribute to greener building practices. For instance, projects utilizing low-carbon aluminum for features like ceiling battens exemplify how modern design can align with environmental responsibilities, showcasing a commitment to reducing the carbon footprint while maintaining aesthetic appeal.

The evolution of T slot aluminum extrusion profiles has been significantly influenced by technological advancements, particularly in CAD (Computer-Aided Design) and automation. These tools have not only streamlined the design process but also enhanced the flexibility and efficiency of creating custom solutions. With CAD software, designers can visualize complex structures and make real-time adjustments, allowing for innovative applications that were previously difficult to achieve. This rapid prototyping capability means that iterations can be tested and modified swiftly, reducing lead times and fostering creative experimentation.

Moreover, automation in manufacturing processes complements the capabilities of CAD by enabling precise fabrication of T slot profiles. Automated machinery can handle intricate designs with consistent quality and repeatability, ensuring that even the most complex configurations can be reliably produced. This synergy between advanced design software and automated production lines empowers engineers and designers to push the boundaries of what is possible in modern design, leading to more versatile and adaptable structures that meet the diverse needs of various industries. The result is a transformative shift in how T slot aluminum extrusions are utilized, allowing for greater innovation and efficiency in contemporary applications.