In the ever-evolving landscape of manufacturing, understanding the intricacies of Aluminum Frame Extrusion Profiles is critical for engineers and designers alike. As the global demand for aluminum products continues to surge—projected to reach nearly 78 million metric tons by 2025 according to the Aluminum Association—choosing the right extrusion profile can significantly impact both performance and cost-efficiency. These profiles are pivotal in applications ranging from structural frameworks to intricate architectural designs, necessitating a deep dive into industry standards and specifications. By aligning with these guidelines, companies can ensure optimal strength, durability, and aesthetic appeal, ultimately leading to a competitive edge in the market. This guide will illuminate the essential factors to consider when selecting Aluminum Frame Extrusion Profiles, empowering stakeholders to make informed decisions that enhance their projects and meet industry benchmarks.

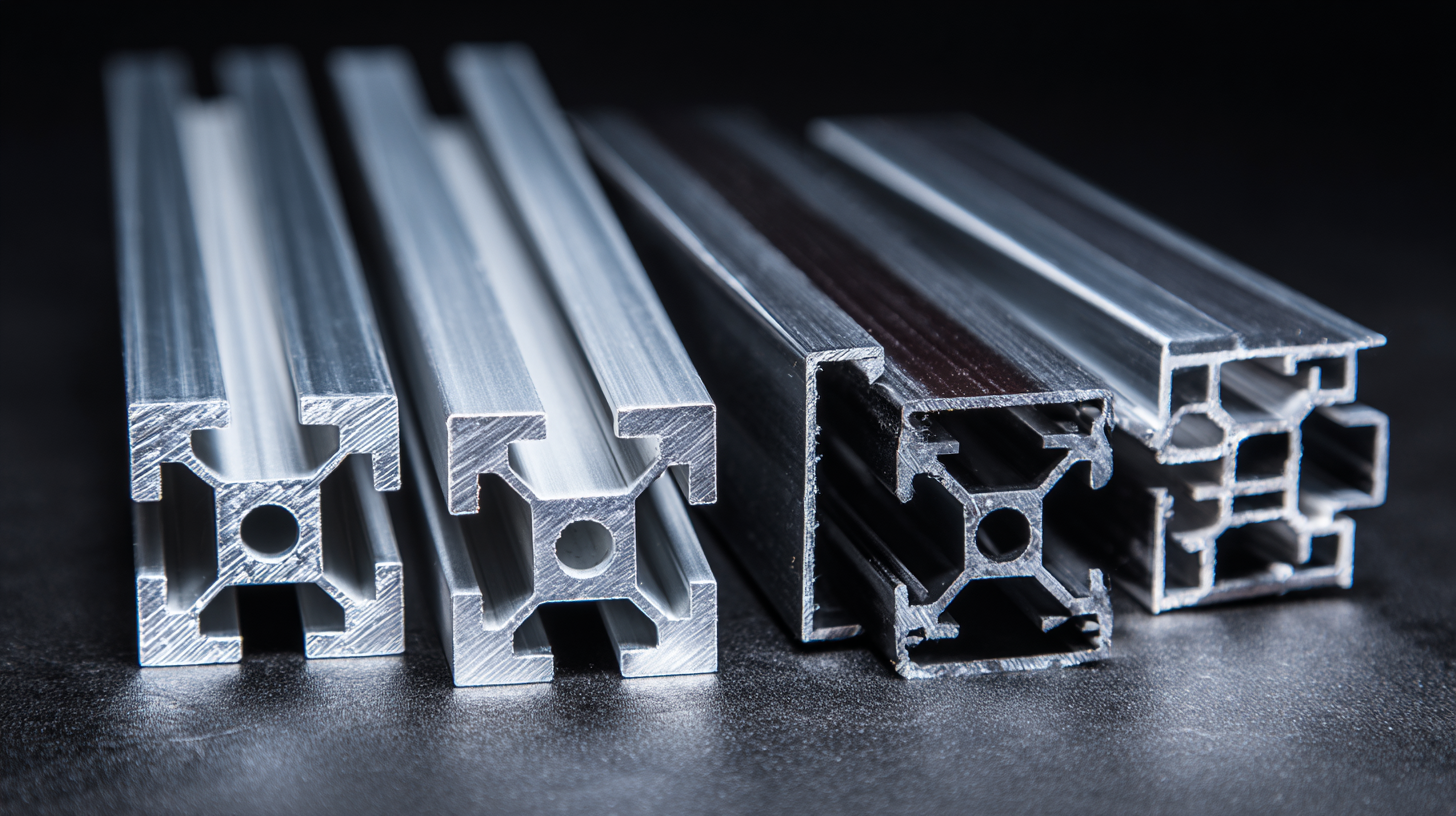

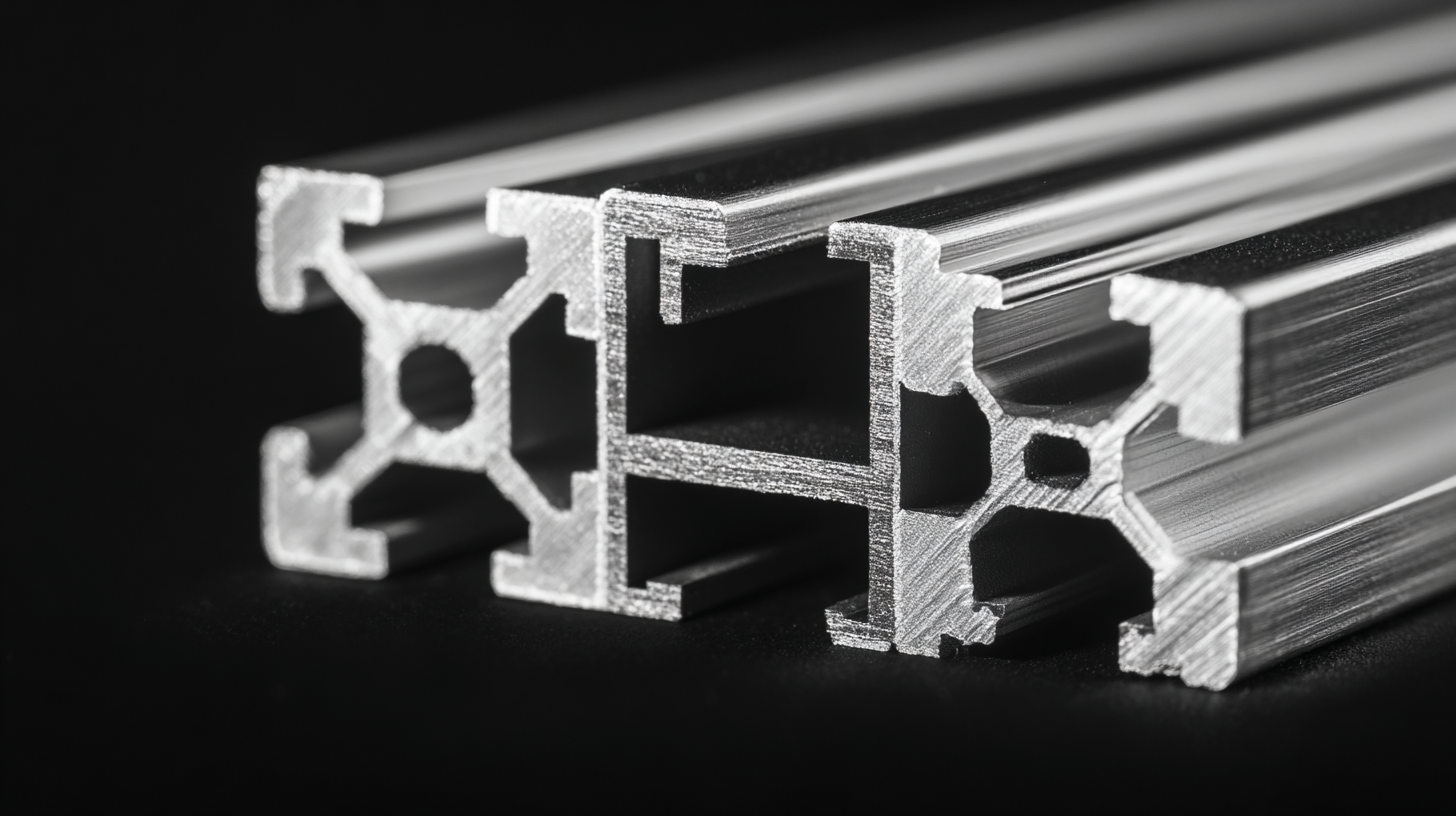

When selecting aluminum frame extrusion profiles, understanding their key characteristics is essential for ensuring quality and performance. One of the primary factors to consider is the alloy used in the extrusion process. Various aluminum alloys possess distinct properties, such as strength, corrosion resistance, and weight, which can significantly affect the profile's suitability for specific applications. Common alloys like 6061 and 6063 are popular due to their excellent mechanical properties and versatility, making them a solid choice for most frame constructions.

Another critical characteristic to evaluate is the finish of the aluminum profile. The surface treatment not only enhances aesthetic appeal but also improves durability. Anodizing and powder coating are two common methods that provide a protective layer, increasing resistance to weathering and physical damage. Additionally, the thickness of the profile walls is a vital aspect, as thicker walls can offer enhanced structural integrity, making them ideal for applications exposed to heavy loads or harsh environments. By carefully considering these characteristics, you can choose the right aluminum frame extrusion profile that meets your project’s specific requirements.

This chart illustrates the key characteristics of quality aluminum frame extrusion profiles, comparing different properties such as strength, weight, and cost-effectiveness.

China has emerged as a global leader in the aluminum extrusion industry, thanks to its advanced manufacturing capabilities and technological innovation. According to a report by the China Nonferrous Metals Industry Association, the country produced over 11 million tons of aluminum extrusions in 2022, accounting for nearly 50% of the world's total output. This massive production capacity is complemented by a robust supply chain and a skilled workforce, enabling Chinese manufacturers to meet diverse market demands efficiently.

Choosing the right aluminum frame extrusion profile is critical for various applications, and selecting a manufacturer with a strong reputation for quality is essential. Tips for selection include verifying certifications such as ISO 9001, which indicates adherence to quality management standards, and examining the manufacturer's production capabilities. Check for vertical integration, which often leads to better quality control, from raw material sourcing to the final product.

Moreover, consider the manufacturer's experience with specific applications. For instance, companies specializing in automotive or aerospace industries may provide profiles that meet more stringent regulatory requirements. Understanding the industry standards and aligning them with your specific needs will ensure that you select the most suitable partner in your aluminum extrusion projects.

When selecting aluminum frame extrusion profiles, several key factors should be considered to ensure optimal performance and durability. First and foremost, the intended application plays a crucial role in the selection process. Different industries may demand varying specifications in terms of strength, weight, and corrosion resistance. For instance, profiles used in architectural applications must meet stringent aesthetic and structural standards, while those for automotive components might prioritize lightweight and high-strength characteristics.

Another important factor is the finish of the aluminum extrusion. Surface treatments, such as anodizing or powder coating, can significantly enhance the material's resistance to wear and environmental factors. These finishes not only improve the longevity of the profiles but also offer aesthetic appeal, allowing customization to fit with design requirements. Additionally, understanding the thermal and acoustic insulation properties of the profiles can greatly influence energy efficiency and comfort in buildings, making it essential to match the extrusion profiles to specific project needs. By carefully assessing these factors, businesses can select the most suitable aluminum frame extrusion profiles for their applications.

China's aluminum frame industry has emerged as a global leader, driven by rapid technological advancements and a strong commitment to innovation. This competitiveness stems from its robust manufacturing capabilities, which allow for the mass production of high-quality aluminum extrusion profiles. By focusing on energy efficiency and lightweight solutions, Chinese manufacturers have been able to create products that not only meet but often exceed international standards. This dedication to quality and performance has positioned China at the forefront of the global market, catering to a wide range of industries from construction to electronics.

Moreover, China's emphasis on research and development has led to breakthroughs in designing customized aluminum extrusion profiles that are suited for specific applications. This versatility enhances the appeal of Chinese aluminum frames, enabling them to compete effectively against established players in Europe and North America. As global demand for sustainable and innovative building materials increases, China's ability to deliver cutting-edge aluminum frame solutions solidifies its status as a dominant force in the aluminum manufacturing sector, setting the benchmark for future developments in the industry.

| Profile Type | Weight per Meter (kg) | Tensile Strength (MPa) | Application Area | Export Competitiveness Factor |

|---|---|---|---|---|

| Standard Frame | 1.5 | 150 | Windows & Doors | High |

| Thermal Break Frame | 1.8 | 180 | Energy Efficient Windows | Medium |

| Heavy Duty Frame | 2.2 | 220 | Commercial Buildings | Very High |

| Architectural Frame | 1.7 | 200 | Modern Architecture | High |

When assessing industry standards for optimal aluminum frame performance, it is crucial to consider the material specifications that align with the application requirements. According to a recent report published by the Aluminum Association, extrusions made from 6061 and 6063 alloys are widely recognized for their robustness and versatility, making them the go-to choices for architectural and structural applications. These alloys not only offer excellent mechanical properties but also display good corrosion resistance, ensuring longevity and reliability in various environmental conditions.

Tip: When selecting an aluminum frame extrusion, always check the alloy specifications and ensure they meet the local building codes and industry standards. This will ensure that your chosen profile can withstand the intended loads and conditions.

Additionally, the quality of the extrusion process plays a significant role in the performance of the aluminum frames. The American Society for Testing and Materials (ASTM) emphasizes the importance of tolerances and finishes in extrusion profiles. Tighter tolerances minimize the risk of misalignment, while premium surface finishes can enhance both appearance and performance by reducing the risk of wear and corrosion.

Tip: Look for extrusion manufacturers that adhere to quality certifications like ISO 9001, as these indicators often reflect a commitment to superior production practices and product excellence.