In today's rapidly evolving manufacturing landscape, innovation is paramount, and Industrial Aluminum Profiles are at the forefront of this transformation. According to a report by the Aluminum Association, the global demand for aluminum is projected to reach 86 million metric tons by 2025, driven largely by its versatility and lightweight properties. Industrial Aluminum Profiles are becoming increasingly critical in diverse applications, from automotive to construction, due to their structural integrity and design flexibility. The capacity to customize these profiles enhances their appeal, allowing manufacturers to optimize production processes and reduce overall costs. As industries seek sustainable solutions, aluminum's recyclability and low carbon footprint make Industrial Aluminum Profiles an essential component of modern manufacturing strategies, unlocking new opportunities for growth and efficiency.

The rise of industrial aluminum profiles has significantly transformed the landscape of manufacturing innovation. These versatile materials, known for their lightweight yet robust properties, are increasingly favored across various industries. Engineers and designers are now able to create complex shapes and structures, facilitating the development of customized solutions that meet specific operational needs. This adaptability not only enhances product functionality but also streamlines the manufacturing process, reducing time and costs.

Moreover, the environmental benefits of aluminum profiles cannot be overlooked. As sustainability becomes a focal point in modern manufacturing, aluminum presents a compelling option due to its recyclability and longevity. Manufacturers are increasingly adopting aluminum profiles in their designs, reducing waste and energy consumption during production. This shift towards more sustainable materials aligns with global trends, pushing companies to innovate continuously while adhering to eco-friendly practices. As such, industrial aluminum profiles are not just shaping products; they are also redefining the principles of how manufacturing aligns with environmental stewardship.

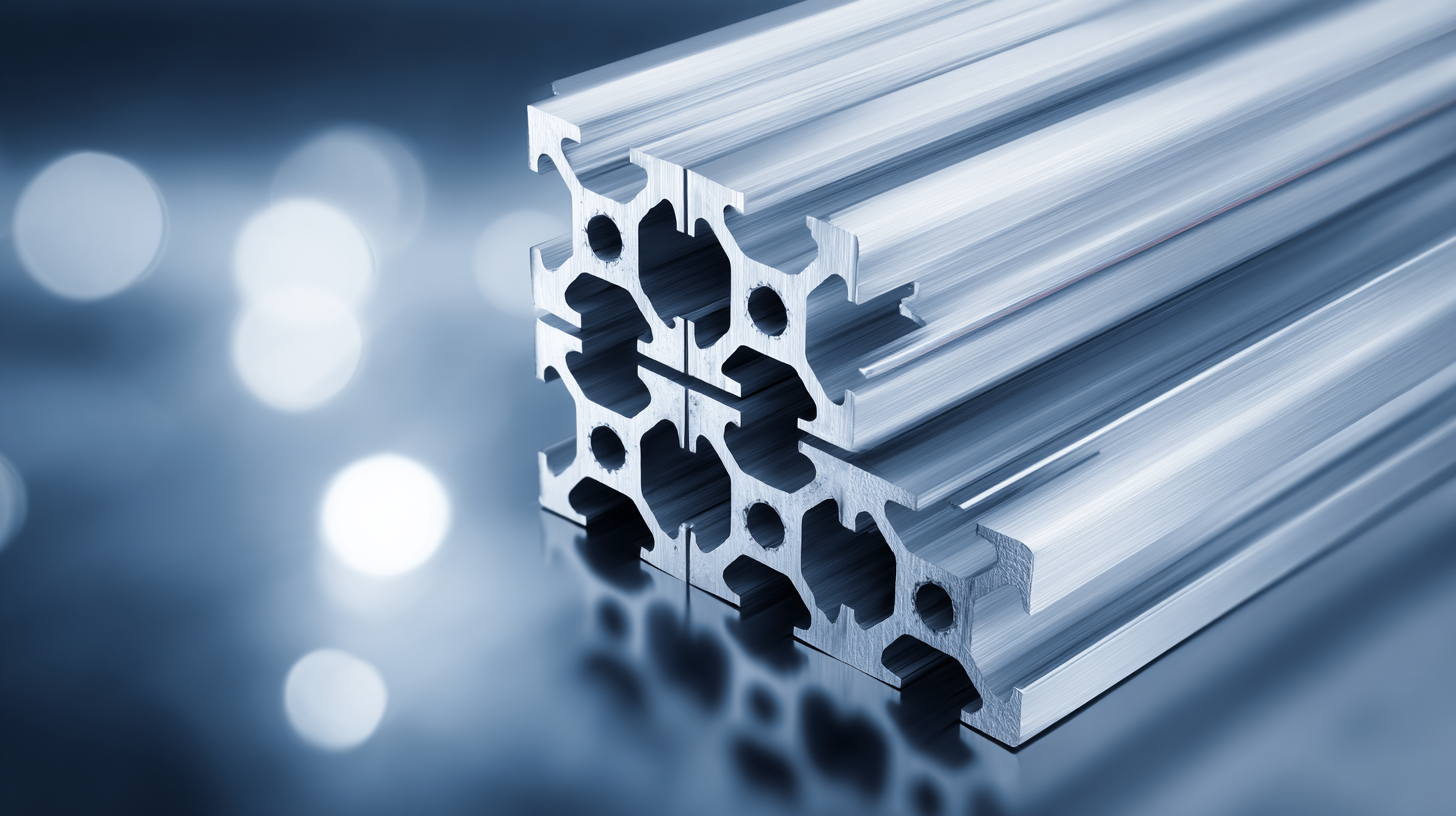

Aluminum profiles have emerged as a game changer in modern manufacturing, offering several advantages over traditional materials such as steel and wood. According to the Global Aluminum Extrusion Market report, the demand for aluminum profiles is projected to reach $85 billion by 2027, indicating a rapid shift in preference among manufacturers. One of the primary benefits of aluminum profiles is their lightweight nature, which translates to lower transportation costs and easier handling during assembly. The density of aluminum is about one-third that of steel, allowing manufacturers to create more efficient designs without compromising strength.

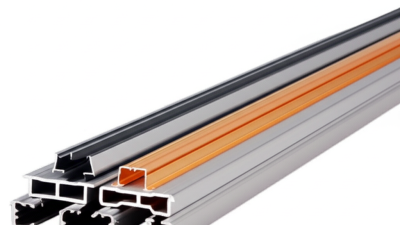

Additionally, aluminum profiles exhibit superior corrosion resistance, which significantly extends the lifespan of products. The Aluminum Association reports that aluminum can withstand harsh environmental conditions without deteriorating, making it an ideal choice for outdoor applications. This durability reduces the need for frequent replacements, ultimately leading to cost savings in the long run. Furthermore, aluminum is highly customizable through extrusion, enabling manufacturers to produce intricate shapes and sizes tailored to specific needs. Overall, these advantages confirm why aluminum profiles are rapidly becoming the preferred choice in various industrial applications, driving innovation in modern manufacturing processes.

The integration of digital technologies in the production of industrial aluminum profiles is revolutionizing modern manufacturing. According to a recent report by the International Aluminum Institute, the global demand for aluminum profiles is expected to grow at a CAGR of 5.8% through 2030, driven largely by advancements in automation and digital production methods. These technologies enhance precision, reduce waste, and improve the overall efficiency of production processes.

Implementing digital tools such as IoT (Internet of Things) and AI (Artificial Intelligence) enables manufacturers to monitor production in real time, streamline workflows, and predict maintenance needs before issues escalate. A survey by McKinsey highlights that companies adopting digital technologies can increase their productivity by up to 30%. This trend towards smart manufacturing not only optimizes resource use but also fosters innovation in product design, allowing for lighter and stronger aluminum profiles that meet the demands of various industries.

Tips for Manufacturers:

In the realm of modern manufacturing, industrial aluminum profiles have emerged as pivotal components that drive innovation and efficiency. Notably, the city of Foshan in China has become synonymous with advanced manufacturing practices, serving as a model for the rest of the industry. According to recent studies, the use of aluminum profiles in manufacturing processes has led to a reduction in material waste by up to 30%, significantly lowering production costs while enhancing product durability.

Case studies from various sectors illustrate the transformative power of aluminum profiles. For instance, in the automotive industry, companies leveraging aluminum structures have reported weight reductions of approximately 30% in vehicle designs, resulting in improved fuel efficiency and lower emissions. Furthermore, the building and construction sector has seen a surge in the adoption of aluminum profiles for structural applications, facilitating faster project timelines and increased design flexibility. The adaptability and lightweight nature of these profiles not only streamline production but also align with the global push towards sustainability, underscoring Foshan’s role as a critical hub in reshaping manufacturing paradigms.

This chart illustrates the percentage of various industries adopting industrial aluminum profiles in their manufacturing processes. The data reflects how aluminum profiles enhance efficiency, reduce weight, and improve design flexibility.

As industries increasingly prioritize sustainability, aluminum emerges as a versatile and eco-friendly material in modern manufacturing practices. With its recyclability and lightweight properties, aluminum profiles play a crucial role in reducing the environmental impact of production processes. From transportation to construction, manufacturers are increasingly leveraging aluminum to enhance energy efficiency while lowering carbon footprints. This shift not only aligns with global sustainability goals but also responds to rising consumer demand for greener products.

Future trends indicate a growing adoption of advanced aluminum alloys and innovative processing techniques. These developments enable manufacturers to create stronger, lighter, and more durable products while minimizing waste. Additionally, the integration of aluminum in emerging technologies, such as electric vehicles and renewable energy systems, underscores its potential to support sustainable practices across various sectors. As these trends evolve, aluminum profiles are poised to redefine manufacturing processes, paving the way for a more sustainable industrial landscape.