Aluminum extrusion plays a vital role in modern manufacturing. This process allows the creation of complex shapes and lightweight structures. Experts like Dr. Emily Turner emphasize its importance by stating, “Aluminum extrusion is crucial for innovation across various industries.”

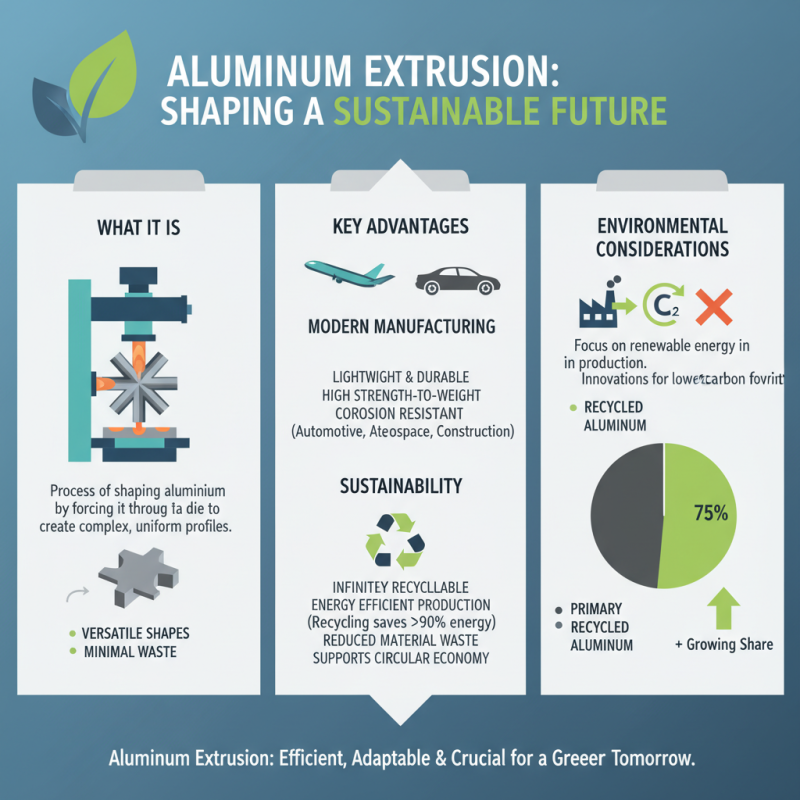

In recent years, the demand for sustainable manufacturing has soared. Aluminum extrusion meets this need due to its recyclability and efficiency. However, challenges remain. Not all manufacturers realize the true potential of aluminum extrusion. Some still overlook its benefits and unique capabilities. This oversight can limit production quality and performance.

As the industry evolves, adapting to new technologies is essential. The integration of advanced methods in aluminum extrusion can enhance precision and supply chain efficiency. Yet, hesitation to invest in these advancements could hinder overall progress. In this landscape, understanding the full value of aluminum extrusion is more crucial than ever.

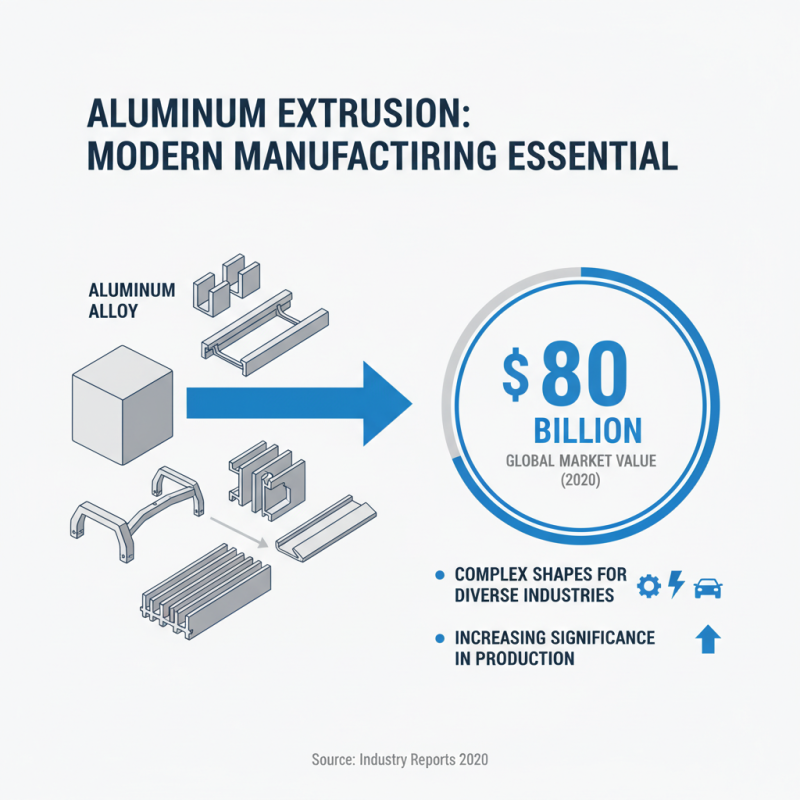

Aluminum extrusion plays a vital role in modern manufacturing. This process transforms aluminum alloys into complex shapes. These shapes cater to various industries. In 2020, the global aluminum extrusion market was valued at approximately $80 billion. This figure demonstrates the material's increasing significance in production.

The advantages of aluminum are numerous. It is lightweight, corrosion-resistant, and recyclable. According to industry reports, aluminum's lightweight nature can lead to a 40% reduction in transportation costs. In construction, aluminum extrusion enables energy efficiency. Buildings with aluminum components can save up to 30% on energy bills.

However, challenges remain. Not all aluminum extrusion processes are optimized. Waste and recycling rates can be inconsistent. The industry needs better solutions for scrap management. Manufacturers often overlook these factors. By addressing inefficiencies, the sector can improve sustainability and reduce costs. These changes are crucial as demand for aluminum continues to rise.

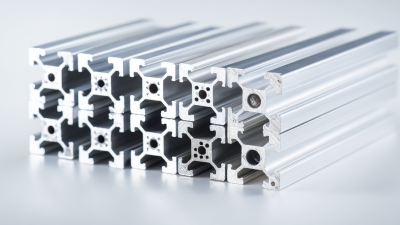

Aluminum extrusions are vital in modern manufacturing. They provide unique advantages across various industries. Lightweight yet strong, aluminum is ideal for aerospace, automotive, and construction sectors. Extruded shapes can be customized to meet specific needs. This flexibility is crucial for product innovation and design.

One key advantage of aluminum extrusions is their corrosion resistance. This characteristic ensures longevity in tough environments. For instance, in construction, aluminum frames withstand the elements better than steel. However, not all aluminum grades are equal. Some may corrode under specific conditions, prompting further research and understanding.

Additionally, the thermal and electrical conductivity of aluminum makes it essential for electronics. Extrusions can be designed for energy-efficient applications, incorporating heat sinks and connectors. This enhances device performance but requires careful design to avoid overheating issues. Balancing efficiency and durability can be a challenge. Nevertheless, with the right approach, aluminum extrusions continue to shape the future of manufacturing.

Aluminum extrusions play a crucial role in modern manufacturing, particularly in the automotive and aerospace sectors. These materials are valued for their light weight and strength. For the automotive industry, reducing vehicle weight is essential for enhancing fuel efficiency. According to a report by the Aluminum Association, replacing steel with aluminum can cut vehicle weight by up to 50%. This translates to significant savings in fuel consumption.

In aerospace, aluminum extrusions are equally vital. They help create structural components that are both lightweight and durable. The Global Aerospace Aluminum Extrusion Market is projected to grow significantly, driven by increasing demand for advanced aircraft. For example, airplanes made with aluminum can improve fuel efficiency by around 10-15%. However, the production processes in both industries face challenges. Extrusion defects can occur, requiring meticulous quality control measures. This is an area where companies must continuously strive for improvement.

While aluminum extrusions have many benefits, there is room for innovation. Current techniques may not always maximize yield efficiency. The industry is exploring new alloys and production methods. Reportedly, enhanced alloys could potentially reduce corrosion and improve performance in extreme conditions. Addressing these gaps will be crucial for future advancements.

Aluminum extrusion plays a vital role in modern manufacturing, especially regarding sustainability and recycling. This process allows the creation of complex shapes and profiles while minimizing waste. Extrusion uses aluminum, which is lightweight and durable, making it ideal for various applications. However, the environmental impact of production methods must be considered.

Recycling is a significant aspect of aluminum production. Aluminum can be recycled repeatedly without losing its properties. This feature makes it an attractive choice for eco-friendly manufacturing. Despite its benefits, the recycling infrastructure is sometimes inadequate. Many facilities struggle with sorting and processing materials efficiently. This gap reflects the need for improvement within the industry.

The energy consumption in aluminum recycling is significantly lower than in primary production. Yet, not all aluminum gets recycled. Ineffective practices and consumer habits contribute to this problem. Awareness and education around recycling can help address these issues. Innovating recycling technologies and improving public engagement remains essential for a sustainable future in aluminum extrusion.

Aluminum extrusion is evolving rapidly. The industry is embracing new techniques to increase efficiency and sustainability. Reports indicate that the global aluminum extrusion market is expected to grow at a CAGR of 5.1% from 2021 to 2028. This growth highlights the increasing importance of aluminum in various sectors, including automotive and aerospace.

Modern innovations are focusing on advanced alloys and improved heat management. Many manufacturers are experimenting with hybrid methods that integrate extrusion with additive manufacturing. This can reduce waste and enhance design flexibility. However, the learning curve can be steep, and not all processes yield perfect results. It's critical for organizations to invest time in training and development.

Tips for manufacturers: Explore partnerships with tech firms to stay updated. Regularly review production techniques to identify inefficiencies. Consider re-evaluating your materials; not all aluminum grades are suitable for every application. Balancing innovation with practicality is essential for future success. Hidden challenges often lie in implementation, not just design.

The aluminum extrusion market has shown significant growth from 2021 to 2025, highlighting its importance in modern manufacturing processes. This chart illustrates the increasing market size, driven by innovations and advancements in aluminum extrusion techniques.