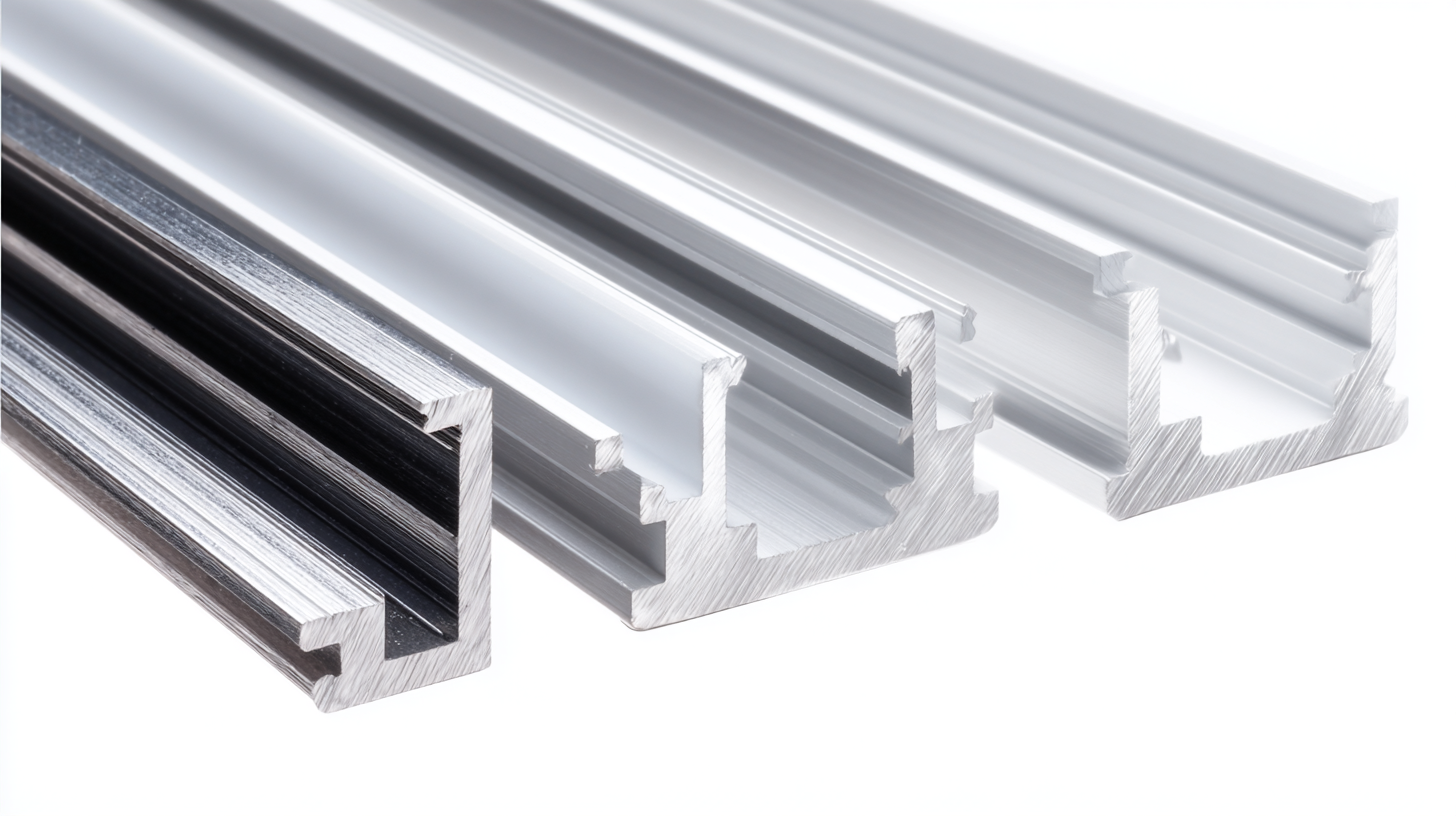

In the world of manufacturing, ensuring compliance with import and export certifications is crucial, especially for industries dealing with essential materials such as Aluminum Moulding Profiles. These profiles serve a vital role in numerous applications ranging from construction to automotive design, making their standards of quality and certification paramount for successful trade.

Navigating the complex landscape of industry production standards can be challenging for manufacturers seeking to optimize their operational efficiency and market accessibility. This blog will delve into the necessary certifications required for Aluminum Moulding Profiles, providing a comprehensive guide on how to effectively manage these regulations. By understanding the steps involved in obtaining and maintaining the right certifications, businesses can not only enhance their credibility but also ensure seamless entry into global markets, ultimately leading to improved profitability and customer satisfaction.

Navigating the complexities of import and export certifications is crucial for businesses dealing with aluminum moulding profiles. According to a report by the Aluminum Association, the global aluminum market is projected to reach $250 billion by 2025, highlighting the increasing demand for high-quality aluminum products. Compliance with relevant certifications not only ensures product quality but also opens doors to international markets. Understanding the specific regulatory requirements in different regions can be the difference between seamless trade and costly delays.

Moreover, adherence to certifications such as ISO 9001 and ASTM International standards is essential for manufacturers aiming to meet industry benchmarks. A study by the International Trade Administration found that companies with proper certification experience 30% higher export success rates, emphasizing the competitive advantage that comes from being compliant. As industries turn toward sustainable practices, certifications related to environmental safety, like LEED, are also becoming increasingly important. These certifications validate the commitment to sustainability and can significantly influence purchasing decisions in a market that is increasingly driven by eco-conscious consumers.

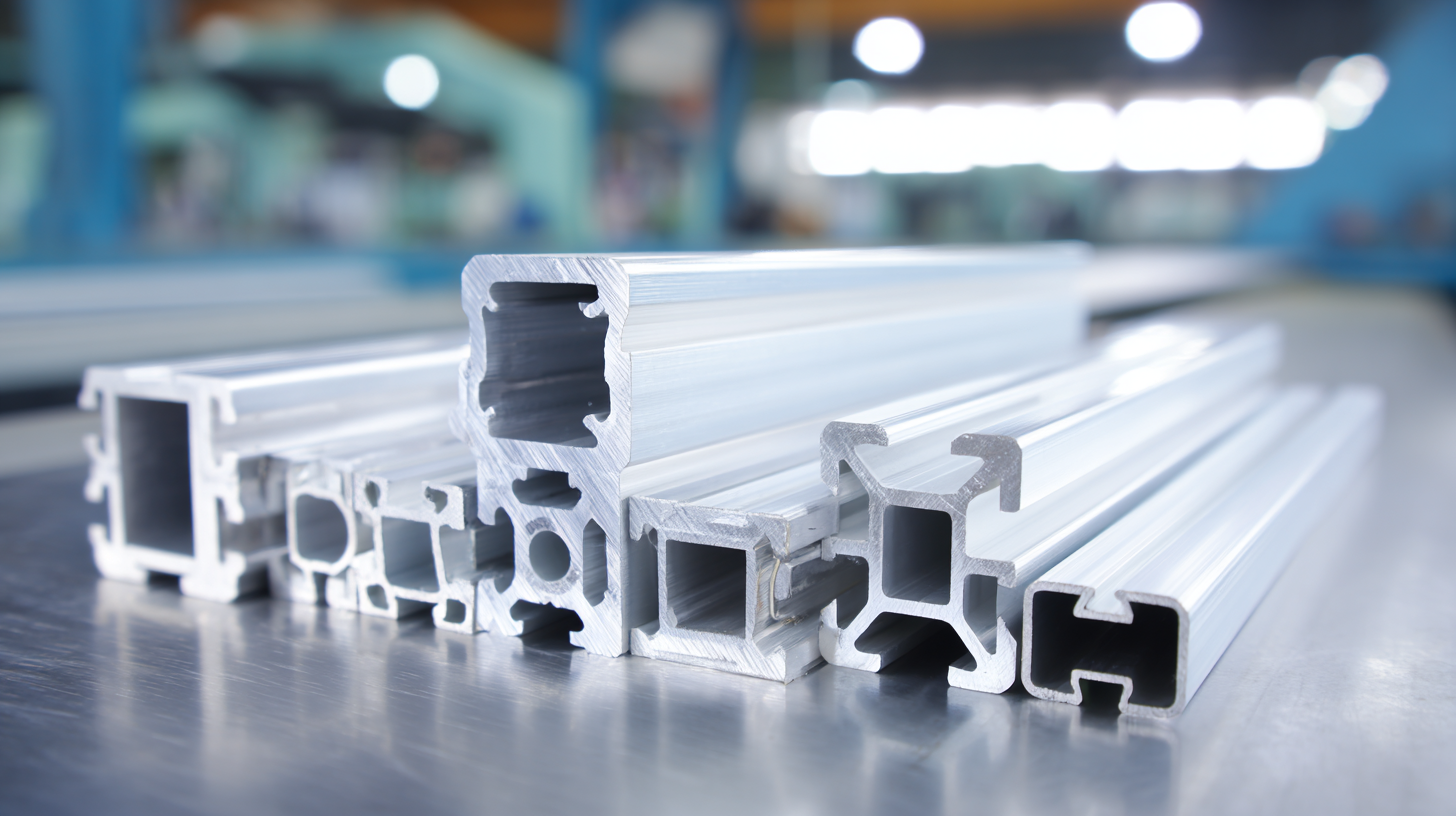

When venturing into international markets, understanding the key certifications for aluminum moulding profiles is essential to ensure compliance and facilitate smoother trade operations. Different regions have specific regulatory requirements that manufacturers and exporters must meet. For instance, certifications like ISO 9001 for quality management systems and ISO 14001 for environmental management play a crucial role in showcasing a company’s commitment to quality and sustainability. These certifications not only build trust with customers but also open doors to various markets that prioritize certified products.

When venturing into international markets, understanding the key certifications for aluminum moulding profiles is essential to ensure compliance and facilitate smoother trade operations. Different regions have specific regulatory requirements that manufacturers and exporters must meet. For instance, certifications like ISO 9001 for quality management systems and ISO 14001 for environmental management play a crucial role in showcasing a company’s commitment to quality and sustainability. These certifications not only build trust with customers but also open doors to various markets that prioritize certified products.

Additionally, particular markets may require compliance with industry-specific standards, such as the American National Standards Institute (ANSI) or the European Norm (EN) standards for aluminum products. These certifications often include testing for mechanical properties, corrosion resistance, and durability, which are vital for products exposed to various environmental factors. By staying informed about these key certifications, businesses can navigate the complexities of import and export regulations, ultimately leading to successful and compliant aluminum moulding exports worldwide.

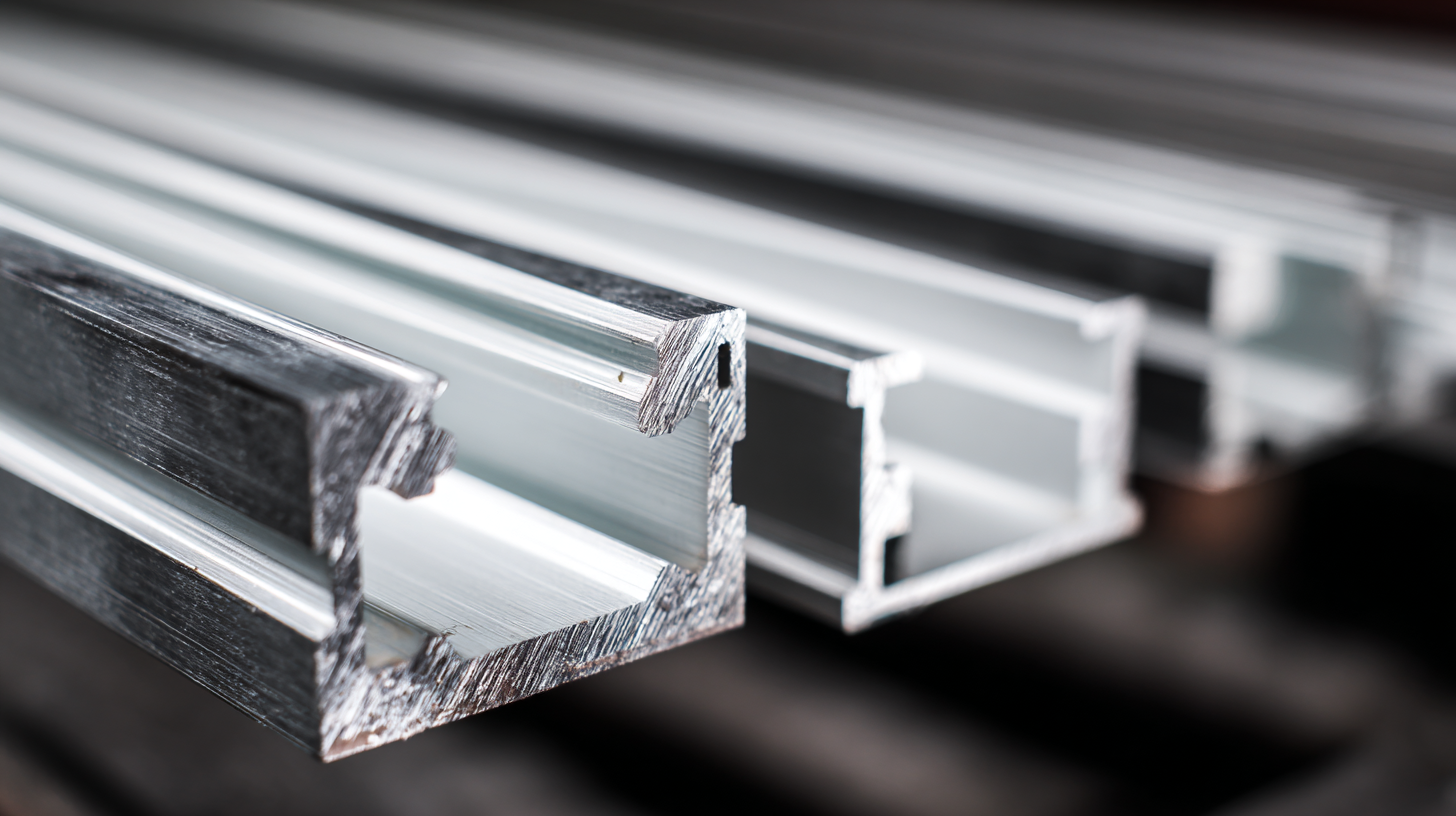

Obtaining the necessary certifications for aluminum products, particularly for moulding profiles, can be a complex and often frustrating process. Common challenges range from understanding specific regulatory requirements to ensuring compliance with international standards. Manufacturers often struggle with the varying criteria set by different countries, which can lead to confusion and potential delays in product launches. The requirement for documentation, like material safety data sheets and test reports, adds another layer of difficulty, necessitating meticulous record-keeping and preparation.

Additionally, the testing process for aluminum products can be time-consuming and costly. Many companies find themselves facing long wait times for test results, which can delay the certification process and, ultimately, product delivery. Furthermore, some manufacturers may lack the technical expertise or resources to navigate the intricacies of certification, leading to increased reliance on external consultants or testing facilities, which can be an additional financial burden. As the demand for compliant aluminum profiles grows, overcoming these hurdles becomes essential for businesses aiming to succeed in a competitive market.

| Certification Type | Description | Common Challenges | Resolution Strategies |

|---|---|---|---|

| ISO 9001 | Quality Management Systems | Understanding requirements | Training staff, consulting experts |

| CE Marking | Conformity to health and safety standards | Complex testing requirements | Hiring certified testing labs |

| RoHS Compliance | Restriction of Hazardous Substances | Assessing materials | Material verification processes |

| REACH Compliance | Registration, Evaluation, Authorisation and Restriction of Chemicals | Tracking chemical substances | Implementing compliance software |

| ANSI Standards | American National Standards Institute | Keeping up with updates | Regular audits and reviews |

Navigating the complexities of import and export certifications for aluminum moulding profiles can significantly impact a company's bottom line. As the global market for aluminum products continues to grow, driven by a projected increase of over 4% CAGR through 2025, organizations must streamline their certification processes to remain competitive. Proper certifications not only facilitate smoother international trade but also ensure compliance with regional regulations, which vary widely.

To effectively navigate this landscape, companies should adopt strategic approaches, such as engaging with industry experts who understand the nuances of local laws and international standards. A recent industry report highlights that businesses that leverage technology-driven compliance management systems reduce certification processing times by up to 30%. Additionally, forming strategic alliances, like that between two manufacturing powerhouses, can help leverage shared expertise in navigating regulatory hurdles. By optimizing their certification processes, companies can enhance operational efficiency and focus on driving innovation in their aluminum moulding capabilities.

In today's global marketplace,

compliance with import and export certifications

is not just a regulatory requirement; it's a strategic advantage that can significantly enhance the competitiveness of aluminum moulding profiles. Certifications serve as a mark of quality and reliability, assuring customers that products meet rigorous safety and performance standards. This builds trust and can lead to increased customer loyalty, as consumers are more likely to choose products from certified manufacturers over those without credentials.

Moreover, compliance with these certifications often opens doors to new markets. Foreign buyers frequently require specific certifications to import products, and being compliant can simplify the negotiation process. It ensures that manufacturers can meet international standards, paving the way for increased export opportunities. In addition, certified companies often enjoy preferential treatment in bidding processes and can command better pricing due to their demonstrated commitment to quality, ultimately enhancing their market presence and revenue potential.

Thus, investing in import and export certifications is essential for businesses looking to thrive in the aluminum moulding sector.