Choosing the right Aluminum Frame Extrusion Profiles is crucial for various industries. It impacts strength, weight, and aesthetics. With a myriad of options available, making the right decision can be daunting.

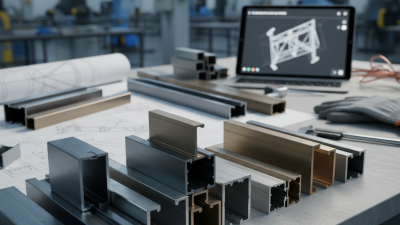

Aluminum profiles come in many shapes and sizes. They can be customized for specific applications. However, it's easy to overlook important details, leading to potential issues down the line. For instance, not every profile will suit your project needs. Quality matters, but so does the cost. Balancing these factors requires careful consideration.

Reflect on your project requirements. What are the load-bearing needs? Is there a specific design in mind? Taking the time to answer these questions can make a difference. Proper selection can enhance functionality and improve the overall look of your project. Don't rush this choice; revisit options if needed. The right Aluminum Frame Extrusion Profiles should meet your criteria effectively.

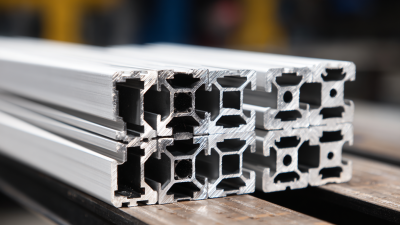

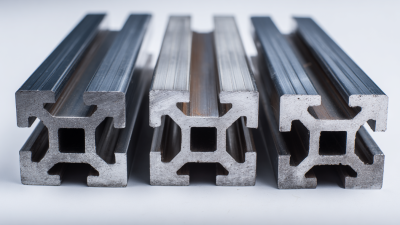

Aluminum frame extrusion profiles are critical in various applications. Understanding their characteristics helps in making informed choices. These profiles offer strength and versatility, making them popular in construction and manufacturing. In 2022, the aluminum frame market size was valued at over $26 billion, showing robust growth potential.

Choosing the right profile is not always straightforward. Factors such as the alloy composition and cross-sectional shape influence performance. A study indicates that 70% of users prioritize strength and durability. However, aesthetic designs often lead to a compromise in these areas. Many fabricators encounter challenges when balancing functionality with design.

Additionally, it is essential to consider the environmental impact. Aluminum recycling rates are impressive, with 75% of aluminum produced still in use today. This statistic should prompt reflections on efficient material use. The choice of extrusion profiles goes beyond immediate needs, affecting sustainability and future costs. Thoughtful selection can lead to better long-term benefits.

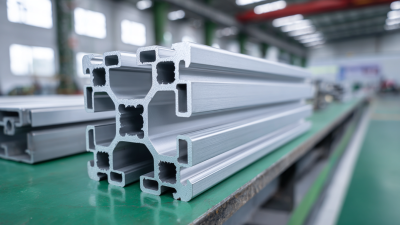

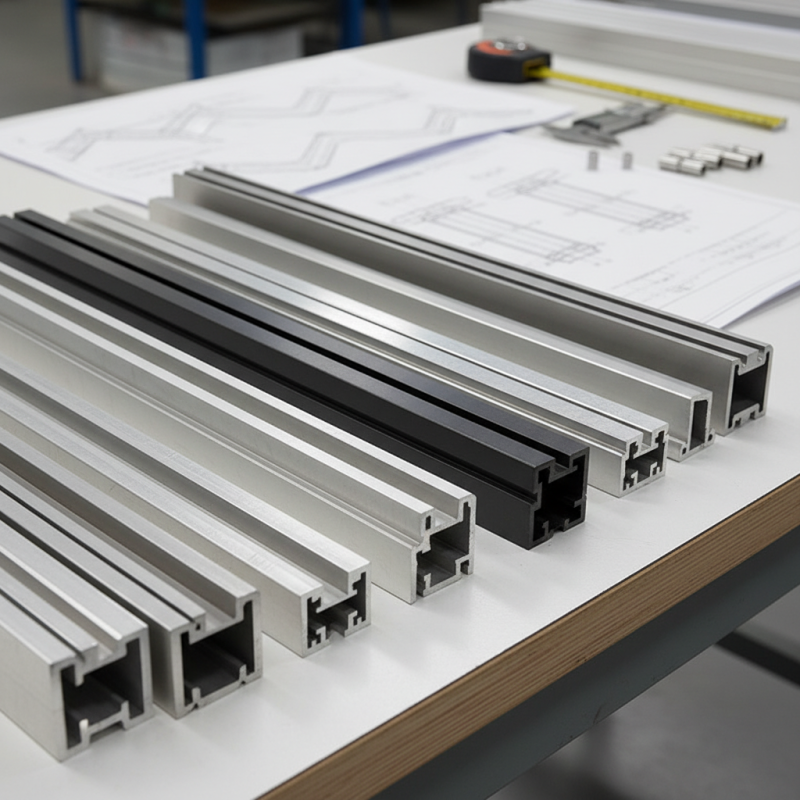

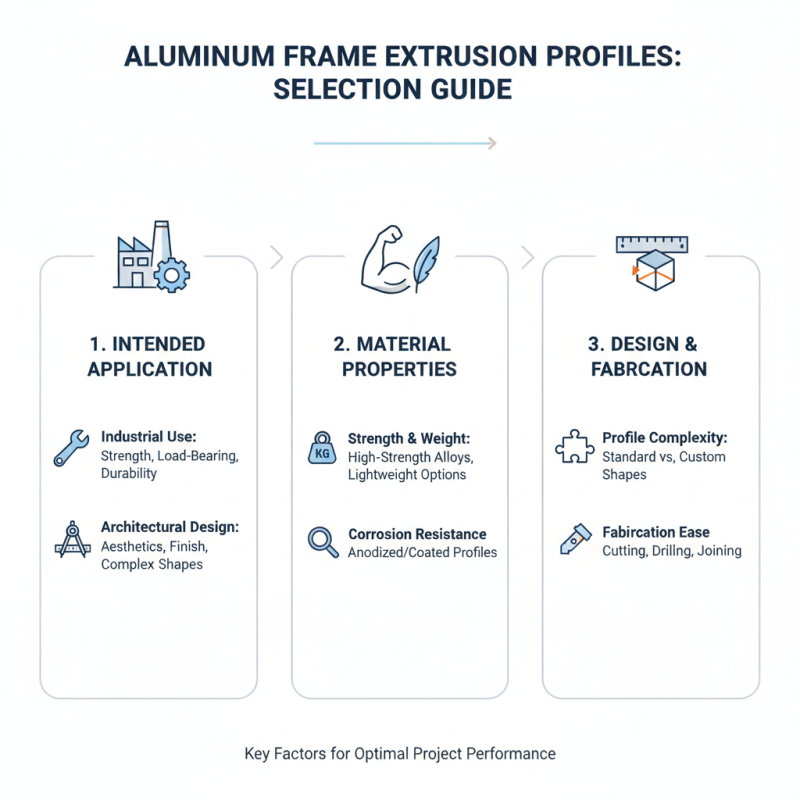

When choosing aluminum frame extrusion profiles, certain factors must be considered carefully. The intended application plays a crucial role. Different projects have varying requirements in terms of strength, weight, and design. For instance, an industrial application might need heavy-duty profiles, while architectural designs may prioritize aesthetics.

Tip: Evaluate the environmental conditions too. Will the profile face moisture or extreme temperatures? Selecting a profile with appropriate resistance can prevent future issues.

Profile dimensions are another important aspect. This includes not just length and width but also the thickness. Thinner profiles can save weight but may compromise strength. You may need to find a balance that meets your needs without leading to unexpected weaknesses.

Tip: Sketch your design before finalizing the profile choices. Visualizing your requirements helps identify potential challenges early on.

Lastly, surface treatment is key. Depending on the profile's exposure, finishes like anodizing can enhance durability. However, the process may sometimes change the profile's appearance. Consider how important aesthetics are for your specific project.

When considering aluminum frame extrusion profiles, the choice of alloy is crucial. Various aluminum alloys offer distinct properties, catering to different applications. Common alloys include 6061, 6063, and 7075. Each has unique characteristics that impact strength, weight, and corrosion resistance.

6061 is versatile. It is often used for structural applications due to its good mechanical properties. However, it is not the lightest option. 6063 is preferred for architectural applications because of its excellent finish. But it might not be strong enough for heavy-duty tasks. 7075 is a high-strength alloy, ideal for aerospace and military uses, yet it's less corrosion-resistant.

Tips: Think about the end-use. Are you aiming for lightweight designs or need maximum strength? Remember, the wrong choice can lead to failures. Look into machining requirements as well. Some alloys are harder to work with than others. Always weigh costs against benefits.

Understanding the properties of these alloys is essential. A misjudgment can impact production and performance. Analyze your project requirements carefully. Select the alloy that best aligns with your goals. Don't rush the decision. Take the time to reflect on your needs, even if it prolongs the process.

| Alloy Type | Characteristics | Common Applications | Strength (MPa) | Weight (g/m) |

|---|---|---|---|---|

| 6061 | Good corrosion resistance, medium strength, weldable | Structures, vehicle frames, marine applications | 240 | 270 |

| 6063 | Excellent finish, good extrusion, moderate strength | Architectural applications, window frames, irrigation tubing | 210 | 275 |

| 7005 | High strength, good weldability, heat treatable | Bicycle frames, structural applications | 480 | 220 |

| 7075 | Very high strength, low corrosion resistance, heat treatable | Aerospace, military applications | 570 | 204 |

| 1050 | High ductility, excellent corrosion resistance, low strength | Chemical and food processing, electrical applications | 90 | 270 |

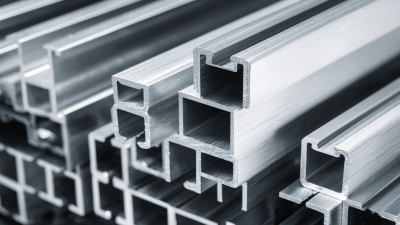

Aluminum frame extrusions have gained traction in various industries due to their versatility. In the automotive sector, lightweight aluminum components contribute to fuel efficiency. Studies show that using aluminum can reduce a vehicle's weight by up to 30%. This translates into better mileage and lower emissions. However, not all manufacturers fully utilize this potential.

In the architectural field, aluminum frames are favored for their durability and aesthetic appeal. They can withstand harsh weather conditions. Reports indicate that over 40% of new commercial buildings employ aluminum frames. Yet, some architects still overlook the benefits of energy efficiency in design. This can lead to increased operational costs in the long run.

The technology industry also benefits from aluminum extrusions. Lightweight and robust, they are used in enclosures for electronics. A report from Market Research Future highlights that the electronics sector accounts for around 25% of aluminum extrusion applications. Despite these advantages, some electronics manufacturers hesitate to adopt aluminum due to cost concerns. Balancing cost and performance is a persistent challenge in this evolving landscape.

When considering aluminum frame extrusions, cost and availability are key factors. The price of aluminum has fluctuated widely in recent years. This impacts project budgets. It's crucial to get quotes from multiple suppliers. Rates may vary significantly across regions. Availability can also be inconsistent. Certain profiles may be in high demand, causing delays.

Additionally, the choice of extrusion profile influences the overall project cost. Standard profiles may be more readily available, but custom profiles can lead to higher expenses. Custom designs often require additional tooling, which can increase costs further. It's a good idea to plan ahead. Lead times for custom profiles can be extended, affecting project timelines.

While sourcing materials, keep a close eye on market trends. Costs can change with tariffs and trade policies. It's wise to have alternative suppliers in mind. This can protect against potential shortages. Remember, not all suppliers provide the same level of service. Sometimes, poor communication can lead to misunderstandings. Always clarify details to ensure a smooth procurement process.