In today's technologically advanced landscape, the demand for durable and efficient housing solutions has led to the rising popularity of Extruded Aluminum Enclosure Profiles. These profiles not only provide robust protection for sensitive electronic components but also offer versatility and aesthetic appeal, making them a preferred choice across various industries. As we look towards 2025, understanding the evolving market dynamics and emerging trends in the extrusion industry becomes crucial for manufacturers and consumers alike. This comprehensive guide aims to explore the various factors that influence the selection of the best Extruded Aluminum Enclosure Profiles, including performance metrics, environmental considerations, and cost efficiency. By examining real-world examples and anticipated market shifts, this blog will equip readers with the knowledge necessary to make informed decisions in an increasingly competitive marketplace.

When it comes to selecting extruded aluminum enclosure profiles, several key factors must be considered to ensure that the chosen design effectively meets its intended application. One critical aspect is the durability of the material. Aluminum is naturally resistant to corrosion, making it an excellent choice for outdoor applications. However, profiles with thicker walls provide even greater resilience, offering protection against physical impacts and harsh environmental conditions. Assessing the specific environmental challenges—such as moisture exposure, temperature fluctuations, and UV radiation—can guide your choice in selecting a more robust profile.

Another important factor is the thermal management capability of the enclosure. Effective heat dissipation is crucial for electronic components housed within these enclosures. Opting for designs with built-in heat sinks or those that maximize surface area can help in maintaining optimal operating temperatures. Additionally, consider the internal dimensions and layout of the enclosure. Adequate space for wiring, ventilation, and potential expansions ensures a functional design that enhances the performance of the enclosed equipment. Balancing these considerations will lead to better functionality and longevity for your extruded aluminum enclosure profiles.

| Profile Type | Dimensions (mm) | Weight (kg/m) | Material Thickness (mm) | Application Suitability | Cost (USD/m) |

|---|---|---|---|---|---|

| Enclosure Type A | 200 x 100 x 50 | 1.5 | 2.0 | Electronics Protection | 50 |

| Enclosure Type B | 300 x 150 x 80 | 2.0 | 2.5 | Outdoor Applications | 75 |

| Enclosure Type C | 250 x 120 x 60 | 1.8 | 2.2 | Industrial Equipment | 65 |

| Enclosure Type D | 350 x 180 x 90 | 2.5 | 3.0 | Automotive Use | 85 |

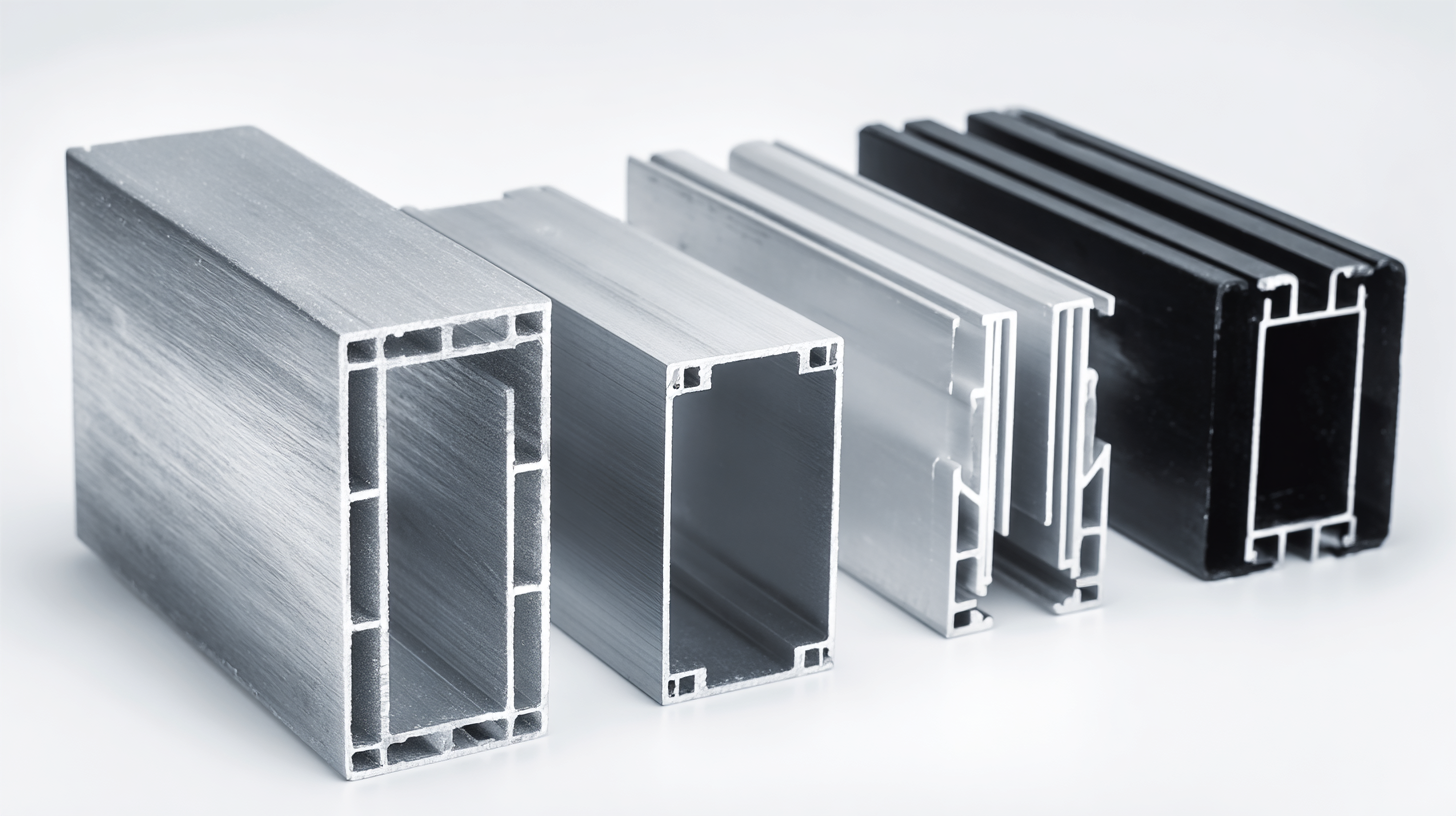

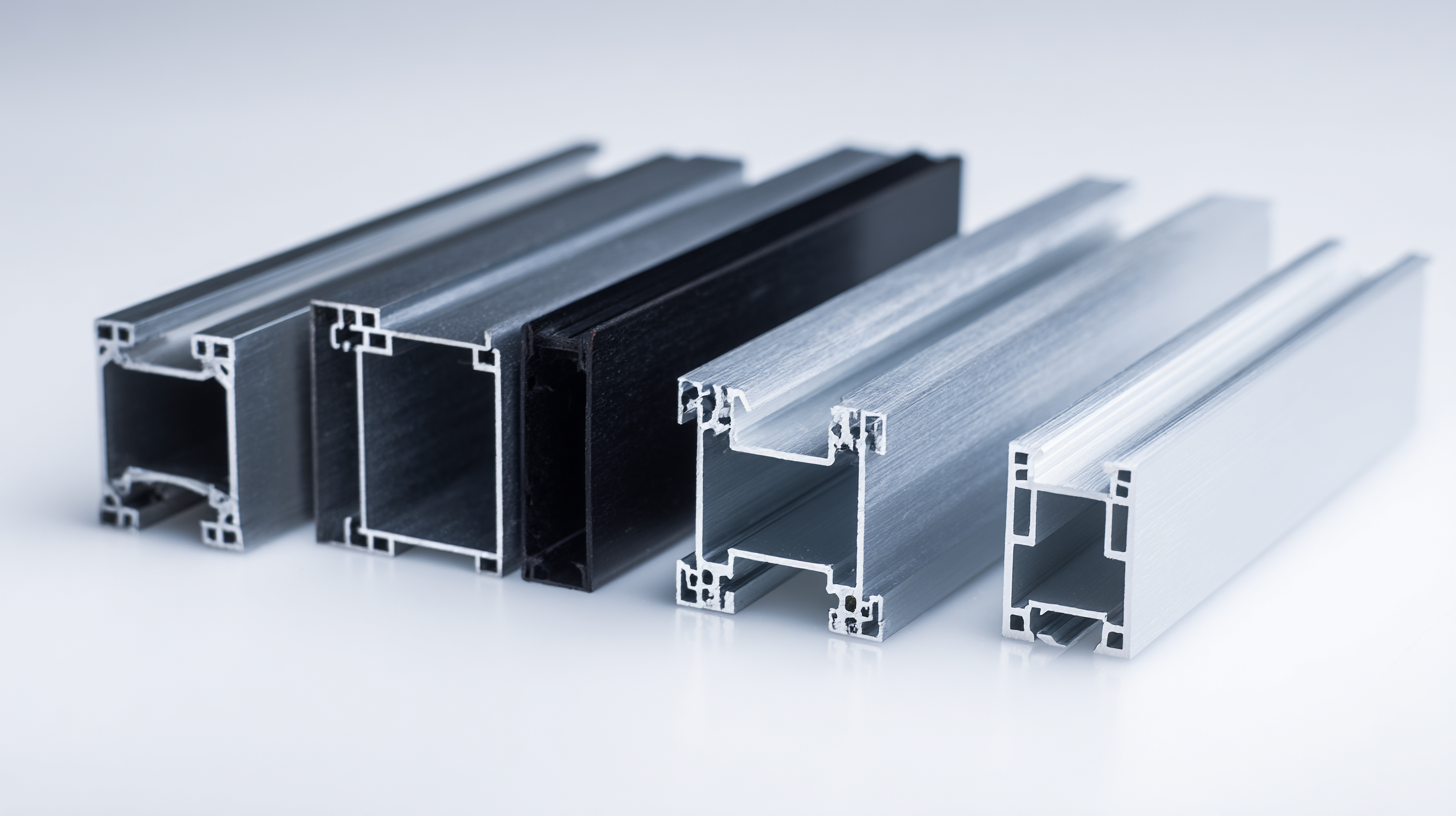

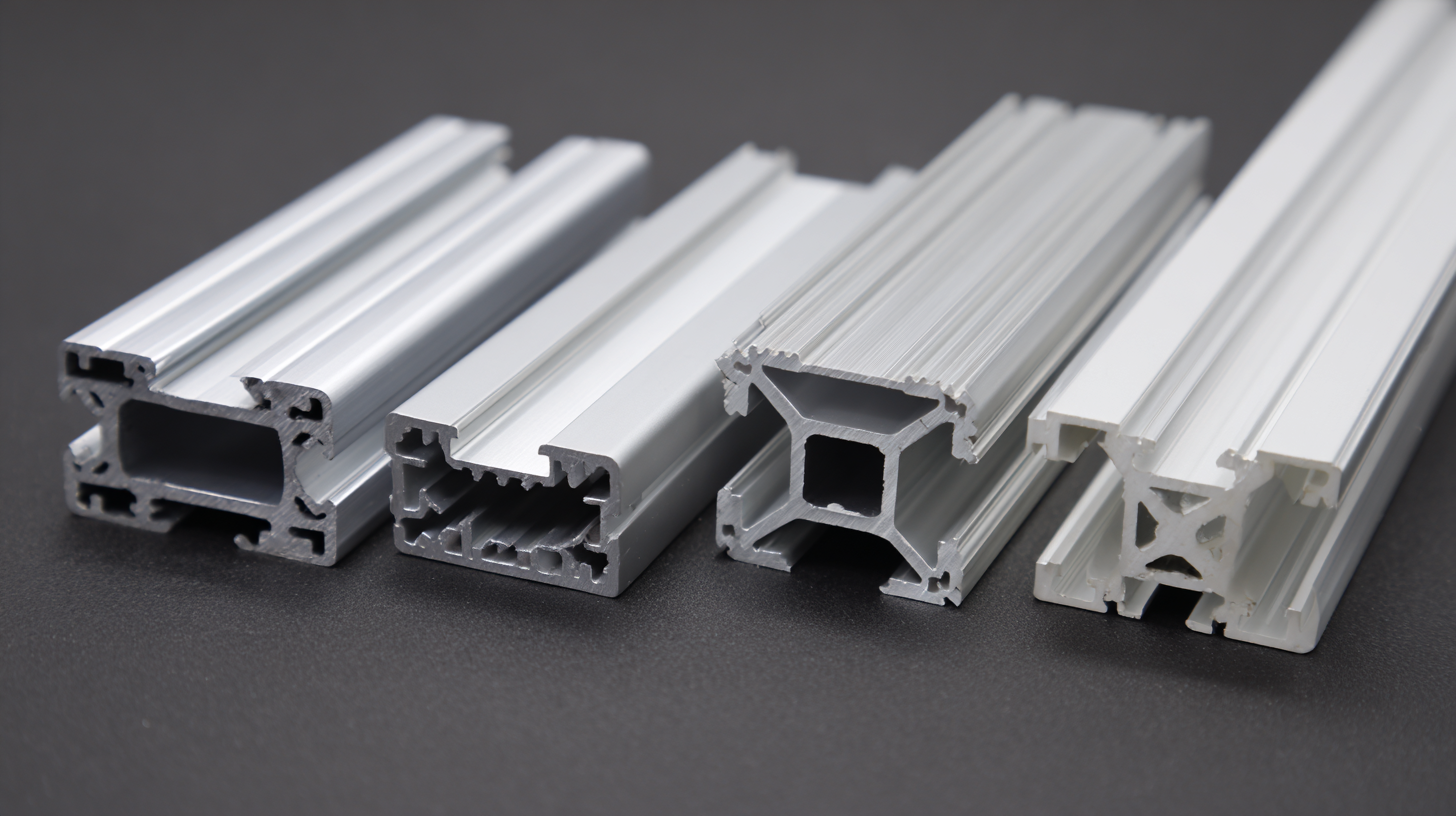

When it comes to selecting the right extruded aluminum enclosure profiles, understanding the different types and their applications is key to making an informed decision. Extruded aluminum profiles can generally be categorized into several types based on their design and intended use. Common profiles include standard enclosures, custom shapes, and modular systems, each serving unique functional requirements. Standard enclosures are ideal for general applications, offering versatility and ease of use, while custom shapes allow for more tailored solutions that meet specific design criteria.

Moreover, modular systems gain popularity due to their adaptability and scalability in various projects. These profiles can be easily assembled or reconfigured as project needs evolve, making them a practical choice for both temporary setups and permanent installations. Understanding the inherent characteristics of each profile type, such as weight, thermal properties, and resistance to environmental factors, can greatly influence the performance of your enclosure.

Ultimately, choosing the right aluminum enclosure profile requires a thorough consideration of these attributes in relation to your project’s unique demands.

When evaluating the durability and strength of aluminum enclosures, it is essential to consider several key factors. First, the alloy used in the extrusion process determines the overall mechanical properties of the enclosure. Common alloys like 6061 and 6063 offer excellent strength-to-weight ratios, with 6061 typically providing superior strength in demanding applications. Additionally, the temper designation of the alloy plays a significant role; for instance, T6 temper indicates that the material has been heat-treated to enhance its mechanical properties, making it more resilient to deformation and impacts.

Another crucial aspect to assess is the enclosure's design and the presence of reinforcing features. A well-engineered profile may include ribs or gussets that increase load-bearing capacity and resistance to bending or twisting under stress. Furthermore, evaluating the enclosure's surface finish is important, as coatings such as anodizing not only enhance aesthetics but also provide a protective layer against corrosion and wear, extending the product's lifespan. Testing under simulated operating conditions can also provide insights into how the enclosure will perform, ensuring it meets the specific durability and strength requirements of the intended application.

When evaluating extruded aluminum enclosures, one of the critical factors to consider is thermal conductivity. Aluminum is renowned for its excellent thermal properties, typically boasting a thermal conductivity of around 205 W/m·K, which makes it an ideal material for heat dissipation. Efficient thermal management is essential in applications ranging from electronics to automotive, as it helps to prevent overheating and prolongs the lifespan of components housed within these enclosures.

Tip: When selecting an extruded aluminum profile, examine its wall thickness and surface area, as these characteristics directly influence heat dissipation efficiency. A larger surface area can enhance heat transfer, especially in high-power applications.

Additionally, according to a recent report by the Aluminum Association, optimizing the design of extruded aluminum enclosures can lead to a significant reduction in thermal resistance, which is crucial for maintaining operational temperatures. By incorporating features such as fins or grooves into the design, you can further improve thermal performance.

Tip: Always consider the application environment when evaluating thermal conductivity. For devices exposed to varying temperatures or high heat loads, ensuring that the enclosure has adequate ventilation or heat sinks can make a substantial difference in its effectiveness.

When customizing an aluminum enclosure profile, several design considerations come into play to ensure functionality and aesthetic appeal. One of the first steps is determining the enclosure's intended use, which influences its dimensions, shape, and features. For instance, if the enclosure is to house sensitive electronic equipment, it may require specific cooling provisions, such as ventilation slots or heat sinks, to manage thermal performance effectively.

Tip: Always consider the environmental factors the enclosure will face, such as humidity, temperature ranges, and exposure to corrosive substances. Selecting the right alloy and surface treatment can enhance durability and resistance to elements, prolonging the life of your product.

Another critical aspect to consider is accessibility. Depending on the application, you might need to integrate features like removable panels, cable entry points, or mounting options. Thoughtful placement of these features can facilitate ease of assembly and maintenance.

Tip: Incorporate modular design elements in your enclosure. This approach allows for easy modifications and upgrades down the line, ensuring that the enclosure remains relevant as design requirements evolve.