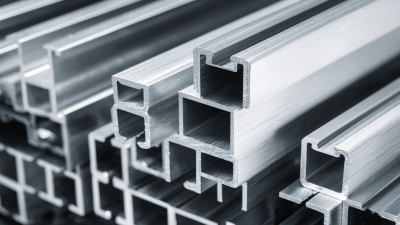

The future of sustainable design is increasingly intertwined with advanced manufacturing techniques, and among these, Aluminum Extrusion stands out as a key player. As industries across the globe strive to reduce their environmental impact, Aluminum Extrusion offers a unique combination of versatility, efficiency, and recyclability, making it an ideal choice for sustainable design. This innovative method not only enables the production of lightweight and structurally strong components but also minimizes waste during the manufacturing process. By harnessing the remarkable properties of aluminum, designers can create products that are not only functional and aesthetically pleasing but also aligned with eco-friendly practices.

In this guide, we will explore how to effectively implement Aluminum Extrusion techniques in sustainable design projects, showcasing best practices and innovative applications that set the stage for a greener future in manufacturing.

The innovative applications of aluminum extrusion techniques are shaping the future of sustainable architecture. With the global aluminum extrusion market projected to reach USD 217.3 billion by 2035, and a compound annual growth rate (CAGR) of 4.6% during the forecast period from 2025 to 2035, this sector is ripe for advancements in sustainable design. Aluminum's lightweight properties, durability, and recyclability make it a favorable material for architects and builders striving to reduce their environmental footprint.

In the Asia Pacific region, the aluminum extrusion market is expected to see significant growth, driven by new product developments in shapes, rods, bars, and pipes and tubes. The projected market dynamics indicate a robust demand for innovative extrusion profiles in sustainable building projects, driven by architects' increasing preference for eco-friendly materials. Additionally, the aluminum profiles and accessories market, estimated at USD 56.35 billion in 2024 with an anticipated CAGR of 8.1% from 2025, underscores the rising trend of using aluminum in various architectural applications, contributing further to the sustainability goals of the construction industry.

The integration of aluminum extrusion techniques with renewable energy solutions presents a promising pathway towards achieving sustainable design. Aluminum, known for its lightweight and durable properties, plays a crucial role in enhancing the efficiency of renewable energy systems such as solar panels and wind turbines. According to a report by the Aluminum Association, the use of aluminum can reduce the weight of solar installations by up to 30%, which can significantly lower installation costs and increase energy production. Incorporating aluminum extrusions in renewable designs not only optimizes functionality but also contributes to the overall sustainability of these systems.

Moreover, aluminum's recyclability adds another layer of sustainability to this integration. The International Aluminum Institute states that approximately 75% of aluminum produced is still in use today, thanks to its ability to be recycled without loss of quality. By utilizing recycled aluminum in extrusion processes, designers can further minimize the carbon footprint of energy solutions. As the renewable energy sector continues to grow, the synergy between aluminum extrusion and these technologies will likely lead to innovative designs and improved performance, reinforcing the industry's commitment to sustainable practices while responding to the increasing demand for clean energy solutions.

The future of sustainable design is increasingly leaning towards lightweight structures, significantly bolstered by aluminum extrusion techniques. As the automotive industry faces mounting pressure to reduce emissions and improve fuel efficiency, materials like aluminum are gaining prominence. The recent evolution in multi-material body designs showcases an innovative shift towards using more aluminum and less steel, resulting in a remarkable 7% reduction in overall vehicle weight. This transformation not only enhances performance but also aligns with the industry's goal of achieving carbon neutrality.

When considering design efficiency, aluminum extrusion offers notable advantages. According to market reports, the aluminum extrusion sector is expected to grow from an estimated value of $44.7 million in 2025 to $63.1 million by 2033, achieving a compound annual growth rate (CAGR) of 4.4%. This growing demand reflects a broader trend towards lightweight construction that is crucial for streamlining energy consumption in the automotive sector.

Tips:

1. Emphasize the role of aluminum in achieving eco-friendly design solutions by integrating it with innovative technologies.

2. Keep abreast of emerging trends in aluminum extrusion for implementing best practices in lightweight structure design.

3. Collaborate with industry experts to maximize the efficiency and sustainability of your designs through tailored material selection.

Aluminum, with its remarkable properties, plays a pivotal role in the evolution of sustainable design within the framework of the circular economy. As a highly recyclable material, aluminum can be repurposed numerous times without degrading its quality, making it an ideal candidate for fostering sustainability. The efficient recycling process of aluminum not only conserves natural resources but also significantly reduces energy consumption compared to primary aluminum production. This aligns perfectly with the principles of a circular economy, where materials are kept in use for as long as possible, minimizing waste and environmental impact.

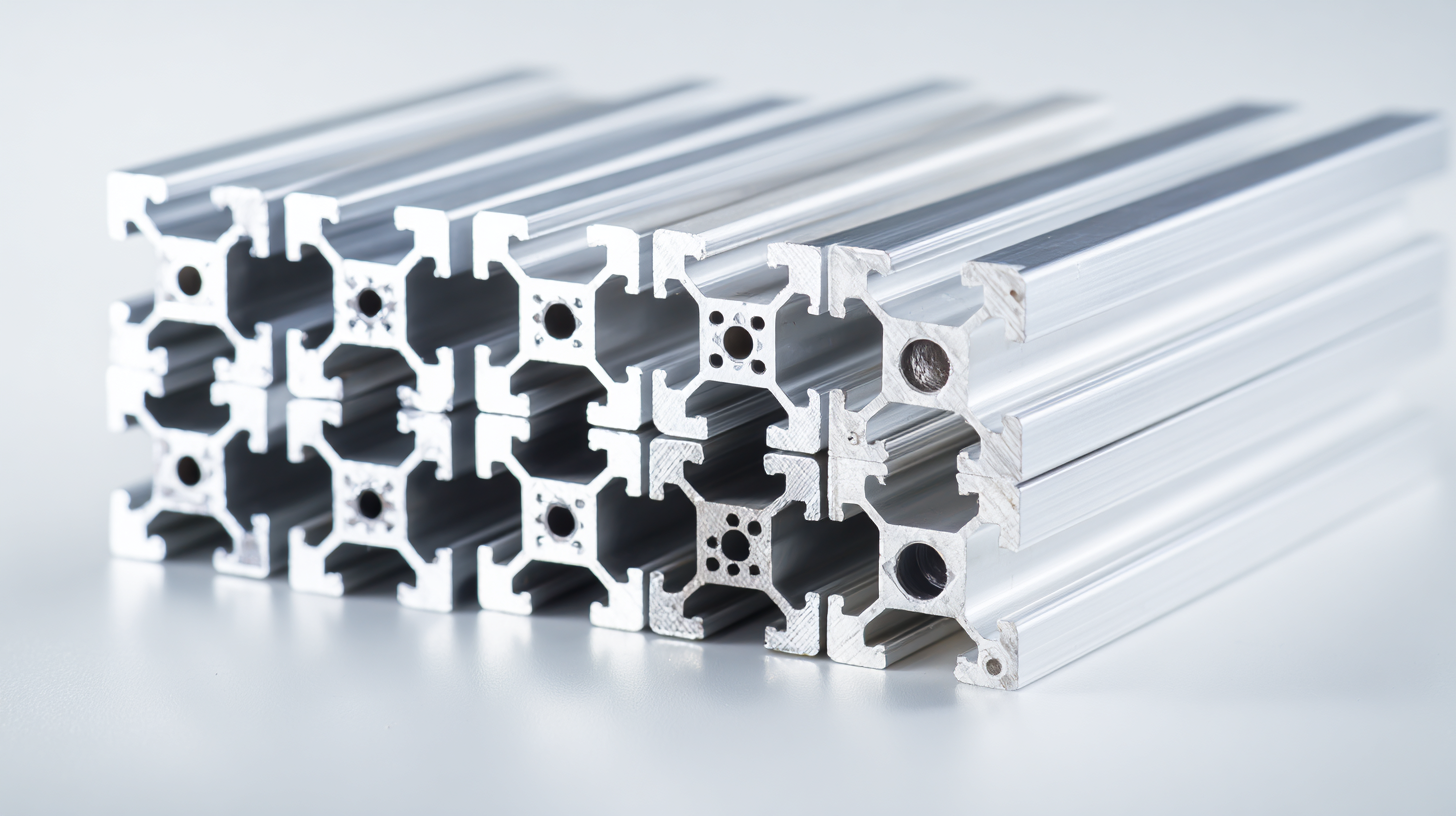

Innovative aluminum extrusion techniques further enhance the sustainability narrative by enabling the creation of complex shapes and lightweight structures that require less material use while maintaining strength and durability. This precision in design reduces scrap during production and allows for the efficient use of recycled aluminum. By integrating such strategies into sustainable design practices, architects and manufacturers can contribute to a greener future, ensuring that products are both functional and environmentally responsible. The synergy between aluminum recycling and advanced extrusion methods exemplifies the potential for sustainability in design to flourish, ultimately fostering a more resilient and circular economy.

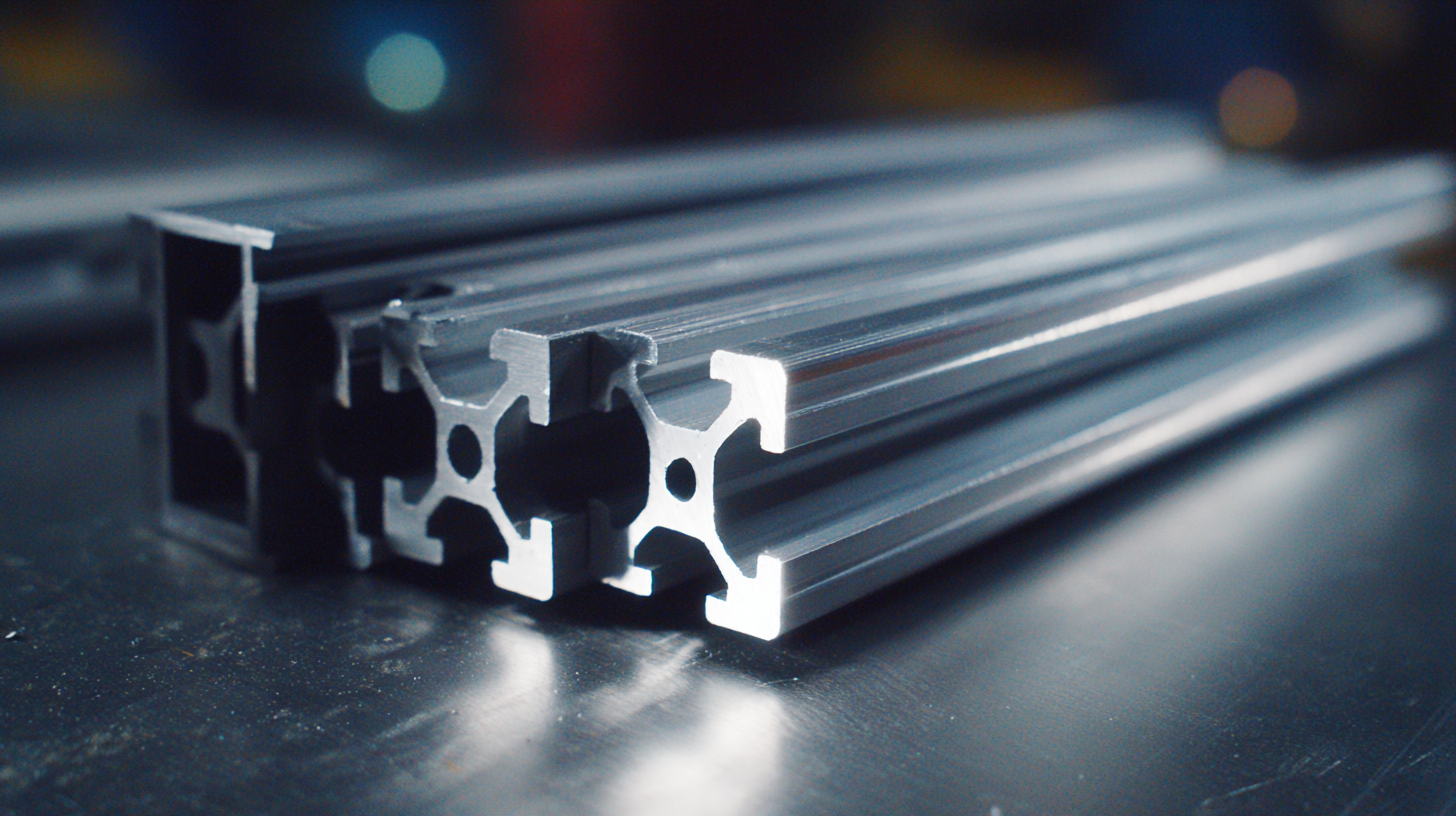

The future of sustainable design is increasingly intertwined with innovative aluminum extrusion techniques, particularly enhanced by the integration of smart technologies. These advancements optimize the extrusion process, resulting in greater efficiency and reduced waste. Machine learning algorithms can now predict and adjust parameters in real-time, ensuring the production of high-quality aluminum profiles while minimizing energy consumption.

Tips for maximizing efficiency in aluminum extrusion include regularly maintaining machinery to prevent downtime and utilizing computer simulations during the design phase. This approach allows manufacturers to test various configurations before physical production, saving materials and time.

Moreover, IoT devices play a crucial role in monitoring production lines, providing crucial data that can lead to continuous improvements. By analyzing this data, companies can identify inefficiencies and implement changes to enhance sustainability. As the industry moves forward, adopting these smart technologies will not only streamline processes but also contribute significantly to environmentally responsible manufacturing practices.