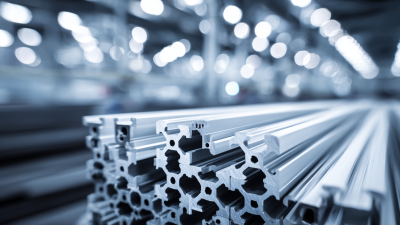

As industries continue to advance towards sustainable and efficient solutions, the significance of Aluminum Extrusion Tube Profiles has gained unprecedented traction. According to a recent market analysis, the global aluminum extrusion market is expected to reach $111.7 billion by 2026, with a compound annual growth rate (CAGR) of 5.5% from 2021 to 2026. This growth is driven by increasing demand across sectors such as automotive, aerospace, and construction, where lightweight and durable materials are paramount.

The 2025 China Import and Export Fair presents a pivotal platform for showcasing cutting-edge advancements in Aluminum Extrusion Tube Profiles, which are essential for optimizing performance and minimizing environmental impact. As manufacturers seek to innovate and expand their product offerings, this fair will be instrumental in revealing the future potential of these profiles in various applications, transforming how industries utilize aluminum in their supply chains.

The upcoming 2025 China Import and Export Fair is set to showcase the latest innovations in aluminum extrusion tube profiles, reflecting a significant trend towards sustainability and efficiency in the industry. According to a recent report by the Aluminum Association, the global aluminum extrusion market is expected to reach $75 billion by 2025, driven largely by demand in sectors such as construction, automotive, and aerospace. This growth is fostering innovative applications of aluminum extrusion, particularly in lightweight structures that offer improved energy efficiency.

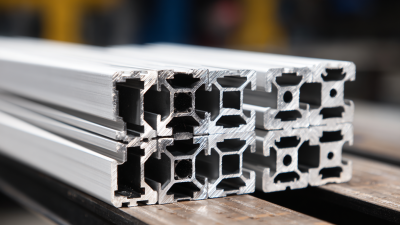

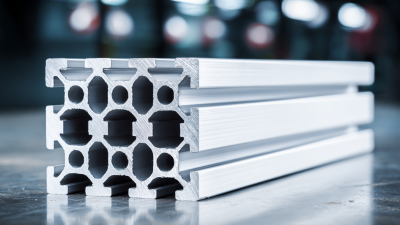

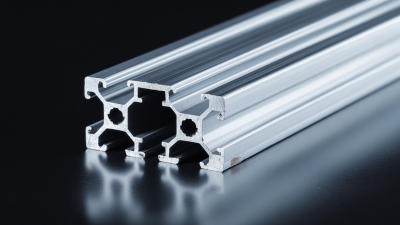

As manufacturers strive to meet evolving environmental standards, advancements in production technologies are leading to the development of more intricate and precise aluminum profiles. These innovations not only enhance structural integrity but also reduce material waste, aligning with global sustainability goals. A study from the International Aluminum Institute indicates that shifting towards such advanced profiles could reduce CO2 emissions by up to 40% in the manufacturing process.

**Tips:** Consider exploring the integration of smart manufacturing processes in your design to optimize production efficiency. Additionally, keep an eye on emerging trends in alloy compositions, as this can significantly influence the performance and sustainability of your aluminum profiles. Engaging with industry experts at trade shows like the China Import and Export Fair can also provide invaluable insights into the latest developments and innovations.

| Profile Type | Applications | Material Grade | Weight (kg/m) | Market Trend |

|---|---|---|---|---|

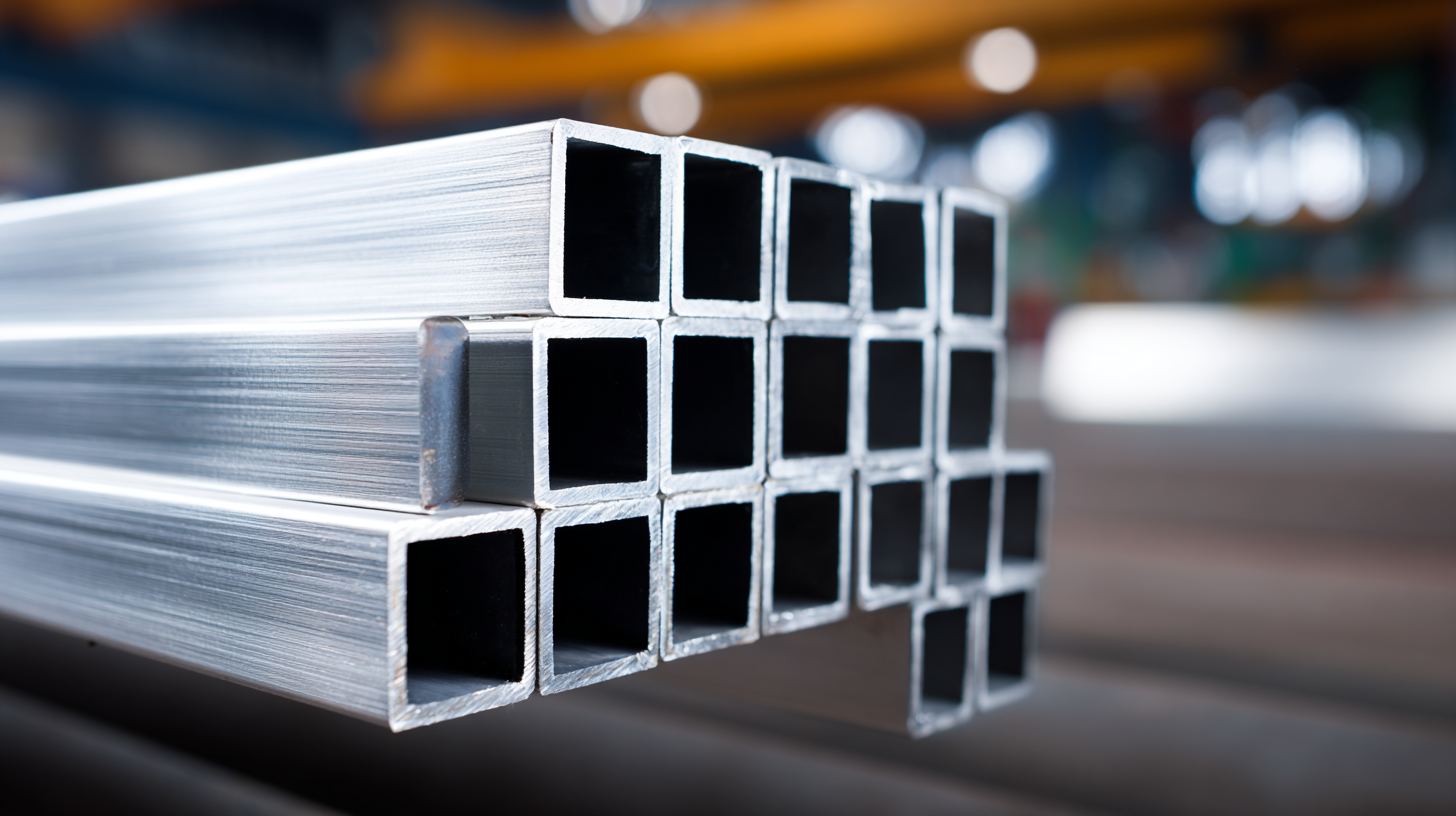

| Round Tube | Construction, Automotive | 6061 | 1.5 | Growing Demand |

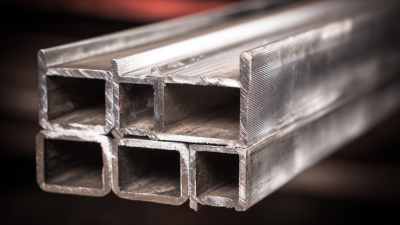

| Square Tube | Furniture, Building Frames | 6063 | 2.0 | Stable Growth |

| Rectangular Tube | Construction, Machinery | 6005 | 2.5 | Increasing Usage |

| Elliptical Tube | Specialized Applications | 6082 | 1.8 | Niche Market |

| Custom Profiles | Various Industries | 7005 | 2.2 | High Demand for Customization |

The 2025 China Import and Export Fair will serve as a pivotal platform for major players in the aluminum extrusion industry to showcase their innovations and solutions. Key exhibitors are expected to present a diverse range of aluminum extrusion tube profiles that cater to various applications, from automotive to aerospace. According to a recent report by ResearchAndMarkets, the global aluminum extrusion market is projected to reach USD 61 billion by 2025, highlighting the robust growth and increasing demand for customized and energy-efficient aluminum solutions.

Leading manufacturers such as Hydro, Constellium, and Alcoa are anticipated to unveil cutting-edge designs and technologies that enhance product performance and sustainability. Industry experts indicate that the shift towards lightweight materials is driving the demand for aluminum extrusions, with the automotive sector estimating a 33% reduction in vehicle weight through the use of aluminum components.

Additionally, the Chinese market is witnessing a surge in investment in green technologies, with forecasts suggesting that aluminum recycling rates could exceed 75% by 2025, further solidifying aluminum's position as a sustainable choice for future applications. The fair will not only highlight the competitiveness of aluminum solutions but also serve as a hub for networking and collaboration among industry stakeholders.

The aluminum industry is at a critical juncture as it seeks to balance high demand with sustainable production practices. As we approach the 2025 China Import and Export Fair, the spotlight will shine on innovations that emphasize eco-friendly methods in aluminum extrusion tube profiles. Key players are increasingly investing in technologies that reduce carbon footprints, enhance recycling processes, and utilize renewable energy sources. This transition not only meets regulatory requirements but also caters to a growing market that prioritizes sustainability.

One promising avenue is the development of closed-loop recycling systems, which significantly minimize waste generated during production. The adoption of advanced technologies allows manufacturers to reclaim and reuse aluminum scrap effectively, thereby conserving resources while maintaining product quality. Moreover, emphasizing sustainable sourcing of raw materials ensures that the entire supply chain contributes to environmental stewardship. As industry leaders gather at the fair, discussions around these innovative practices will pave the way for a greener future in aluminum production, showcasing a commitment to both economic viability and ecological responsibility.

The aluminum industry is on the brink of transformative changes driven by pioneering technological advancements aimed at enhancing sustainability and efficiency. With the Aluminum Fluoride (AlF3) market projected to reach USD 3.12 billion by 2030, significant industry insights are emerging that underscore the growth potential. Recent studies highlight advancements in aluminum recycling technologies, particularly through molten salt electrolysis. This method not only improves the upcycling of aluminum scrap and dross but also exemplifies innovations that could revolutionize resource management in the sector.

Furthermore, the Chinese government's initiative to promote high-quality development in the aluminum sector is critical in addressing trade frictions and enhancing global competitiveness. Whether through modern mining techniques or advanced bauxite alumina processing upgrades, the emphasis on energy transition technologies signifies a collective move towards a low-carbon future. By investing in technologies aimed at CO2 emission reduction, the primary aluminum industry in China is setting a benchmark for sustainable practices that align with global environmental goals. These developments bode well for manufacturers looking to optimize their operations in line with the evolving market landscape.

This chart illustrates the projected growth in production volume of aluminum extrusion tube profiles from 2019 to 2025. The data indicates a steady increase, highlighting the technological advancements and demand for aluminum products in various industries.

The aluminum extrusion tubes market presents both significant opportunities and notable challenges, especially as industries such as automotive and aerospace increasingly turn to lightweight materials. As the demand for energy-efficient and sustainable solutions grows, innovations such as seamless aluminum tubes for hydrogen fuel vehicles highlight the potential of aluminum in leading-edge technologies. This evolving landscape offers avenues for businesses to explore new applications and enhancements in the extrusion process, directly aligning with global sustainability goals.

However, the aluminum extrusion sector is not without its hurdles. Environmental regulations, particularly those targeting waste heat recovery and emissions, are reshaping operational frameworks. Moreover, fluctuations in raw material costs and competition from emerging markets could challenge established players. The recent struggles faced by sectors in regions like Germany underscore the impact of global economic shifts and market volatility on production capabilities. Given these dynamics, adept navigation through regulatory and operational challenges will be crucial for businesses aiming to thrive in the evolving aluminum extrusion landscape.