In the fast-evolving landscape of manufacturing and construction, selecting the right materials is pivotal to the integrity and success of a project. Aluminum Corner Extrusion Profiles have gained significant traction in various industries due to their lightweight nature, corrosion resistance, and excellent structural capabilities. According to the *Global Aluminum Extrusion Market Report 2023*, the industry is projected to reach a market value of $80 billion by 2027, underscoring the growing reliance on aluminum components.

Industry expert Dr. Lisa Chen, a leading materials engineer, emphasizes the importance of making informed decisions when it comes to choosing these profiles. She notes, "A well-chosen Aluminum Corner Extrusion Profile can not only enhance the durability and efficiency of your structures but also lead to substantial cost savings in the long run." This highlights the necessity for stakeholders to be equipped with knowledge on critical factors such as size, strength, surface finish, and application suitability in order to maximize both performance and value. As the focus on sustainability and material efficiency intensifies, understanding the nuances of Aluminum Corner Extrusion Profiles becomes increasingly essential for professionals in the field.

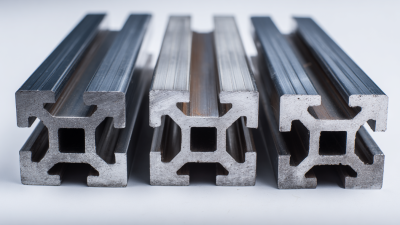

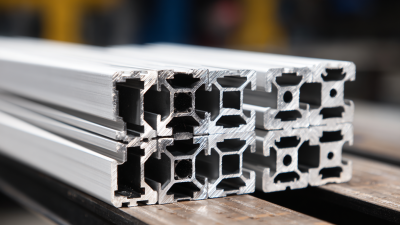

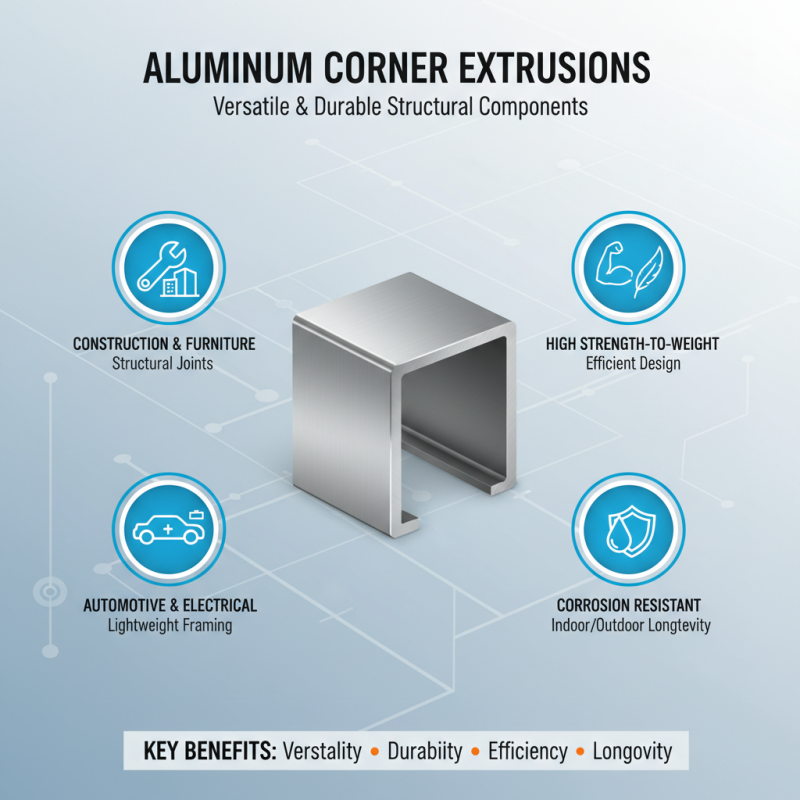

Aluminum corner extrusion profiles are versatile components widely utilized across various industries due to their lightweight yet sturdy nature. These profiles are designed to create structural corners and joints in assemblies, making them ideal for applications in construction, furniture, automotive, and electrical sectors. Their strength-to-weight ratio offers designers the flexibility to create efficient structures without compromising on durability. Moreover, the corrosion-resistant properties of aluminum ensure longevity, even in challenging environments, making them suitable for both indoor and outdoor applications.

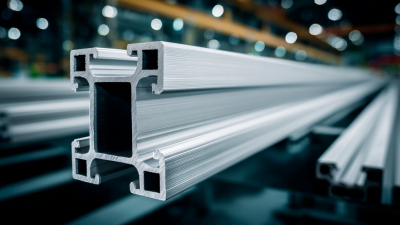

Understanding the specific requirements of your project is crucial when selecting aluminum corner extrusion profiles. Factors such as the intended load capacity, environmental conditions, and design specifications should guide your decision. Different profiles can accommodate various designs, from simple right-angle joints to more intricate configurations. Furthermore, custom extrusion options allow for tailored solutions, enabling manufacturers to achieve precise dimensions and characteristics that meet unique project needs. By recognizing the applications and benefits of aluminum corner extrusions, designers can effectively leverage these profiles to enhance the functionality and aesthetics of their projects.

When selecting aluminum corner extrusion profiles, several key factors must be considered to ensure the optimal choice for your specific application. First and foremost, assessing the required dimensions and tolerances is crucial. Accurate measurements will help determine the profile that fits your project while accommodating any structural demands it must meet. It's essential to consider the thickness of the material as well, as this can significantly affect the strength and durability of the corner extrusions.

Another important factor is the finish and treatment of the aluminum. Various surface finishes, such as anodizing or powder coating, can enhance the corrosion resistance and aesthetic appeal of the extrusions. Examining the environmental conditions the extrusions will face is vital, as certain finishes may perform better in specific climates. Additionally, understanding the intended load and potential stress points will guide you in selecting a profile that offers sufficient strength and rigidity for your application. By considering these factors, you can make a well-informed decision that meets both functional and visual requirements.

| Tip No. | Factor | Description | Considerations |

|---|---|---|---|

| 1 | Material Quality | Select high-grade aluminum to ensure durability. | Check certifications and test reports. |

| 2 | Profile Design | Consider the geometry that suits your project. | Evaluate functional and aesthetic requirements. |

| 3 | Customization Options | Availability of custom profile dimensions. | Discuss customization limits with suppliers. |

| 4 | Surface Treatment | Choose surface finishing options for corrosion resistance. | Consider anodizing or powder coating. |

| 5 | Load-Bearing Capacity | Assess the strength needed for applications. | Use engineering calculators if necessary. |

| 6 | Weight Considerations | Ensure the weight is manageable for installation. | Factor in handling and installation logistics. |

| 7 | Cost Efficiency | Balance quality with budget constraints. | Obtain multiple quotes for comparison. |

| 8 | Supplier Reputation | Work with reliable manufacturers. | Check reviews and customer feedback. |

| 9 | Delivery Time | Consider lead times for manufacturing and shipping. | Plan projects accordingly to avoid delays. |

| 10 | After-Sales Support | Ensure support is available if issues arise. | Confirm warranty and support terms. |

When selecting aluminum corner extrusion profiles, understanding the various shapes and sizes available is crucial for effective application. Corner profiles come in a plethora of geometries, from L-shaped to T-shaped designs, each serving different structural and aesthetic purposes. Analyzing your project requirements will help in determining which shape best suits your needs. Consider the load-bearing capacity, the intended use, and how the profile will integrate with other components in your design.

Tip: Always prioritize the thickness of the wall in the extrusion profile. A thicker wall provides increased strength and durability, essential for high-stress environments. Moreover, evaluating the dimensions of the corner profiles can significantly influence your project’s overall integrity and functionality.

Another critical aspect is the finishing of the aluminum profiles. Surface treatments can enhance corrosion resistance and visual appeal, making it vital to analyze available options. You may choose from anodized finishes, powder coating, or natural finishes, depending on the environmental conditions your project will face.

Tip: When in doubt, consult with a supplier about custom profiles that can meet specific needs that standard sizes cannot fulfill. Customization allows for better integration into unique installations, ultimately resulting in a more effective solution.

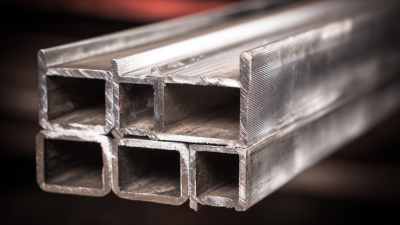

When it comes to selecting aluminum corner extrusion profiles, evaluating strength and durability is crucial to ensuring longevity and functionality in various applications. According to a report from the Aluminum Association, the tensile strength of aluminum extrusions typically ranges from 70 MPa to 700 MPa, depending on the alloy and temper. Choosing profiles with adequate tensile strength is essential for applications that experience varied loads, as insufficient strength can lead to structural failures or deformations over time.

Moreover, the durability of aluminum extrusions is significantly influenced by surface treatment methods. Anodization is one of the most effective surface treatments, providing a protective oxide layer that enhances corrosion resistance. The American Institute of Architects outlines that anodized aluminum can withstand hostile environments better than untreated options, making it a preferred choice for outdoor applications. Testing shows that anodized finishes can extend the lifespan of aluminum profiles by up to 30% compared to non-treated surfaces, which highlights the importance of selecting appropriately treated profiles for enhanced durability. Proper evaluation of these characteristics ensures that the chosen aluminum corner extrusion profiles meet the performance standards required for specific projects.

This bar chart provides an evaluation of the tensile and yield strength of various aluminum extrusions, which are essential factors to consider when choosing the right profile for your needs.

When selecting aluminum corner extrusion profiles, understanding cost-effectiveness is crucial. A key factor in sourcing options is evaluating suppliers based on their pricing models. Seek out vendors that offer transparent pricing structures, allowing you to estimate total costs more accurately. Bulk purchasing can provide significant savings, so consider consolidating your orders to maximize these benefits. Additionally, compare quotes from multiple suppliers to ensure you’re not paying more than necessary.

When choosing aluminum profiles, keep these tips in mind. First, prioritize suppliers who offer high-quality materials to avoid unexpected costs associated with replacements or repairs. Second, analyze the trade-offs between custom versus standard options; while custom profiles may fit specific needs perfectly, they often come at a premium. Lastly, verify the supplier’s reputation—customer reviews and testimonials can offer insights into reliability and service quality, which can impact the overall cost-effectiveness of your decision. By carefully considering these factors, you can better navigate the sourcing process and achieve optimal results in your projects.