In the ever-evolving landscape of construction, the importance of selecting the right materials cannot be overstated. One crucial component, Aluminum Construction Profiles, plays a pivotal role in the efficiency and durability of modern buildings. According to recent industry reports, the global aluminum profile market is projected to reach USD 87.84 billion by 2026, with a significant portion driven by construction applications.

These profiles offer unparalleled advantages, including lightweight properties, corrosion resistance, and design flexibility, making them a preferred choice for architects and engineers alike. However, navigating the myriad options available can be overwhelming.

This essential checklist aims to equip project managers and construction professionals with the critical factors to consider when choosing aluminum construction profiles, ensuring optimal outcomes for every project.

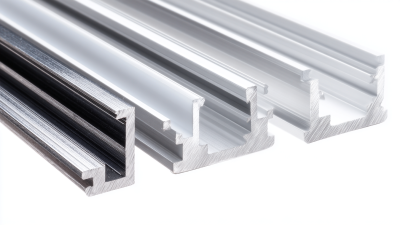

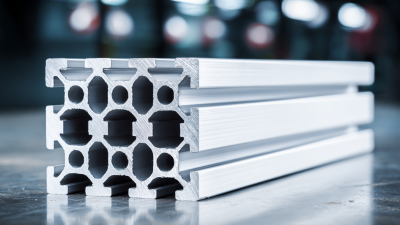

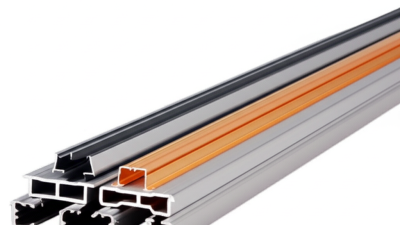

When selecting the right aluminum construction profiles for your project, it’s essential to understand the various types available in the market. Aluminum profiles come in several forms, such as extrusions, rolled products, and alloy variations tailored for specific applications. According to the latest market analysis, the global aluminum extrusion market is projected to reach $87.91 billion by 2030, indicating a significant demand for high-performance aluminum solutions. This rapid growth underscores the importance of choosing the right profiles that meet your project requirements while ensuring durability and cost-effectiveness.

In addition, the Aluminum Wire Rod Market is expected to grow from $30.09 billion in 2025 to $37.78 billion by 2034. This growth is driven by advancements in manufacturing processes and increased application in various sectors, including construction and electrical. With a projected CAGR of 4.5%, aluminum cables and conductors are also gaining traction, further highlighting the diverse applications of aluminum in construction.

Understanding these trends and market dynamics can help you make informed decisions when selecting aluminum profiles tailored to your specific needs.

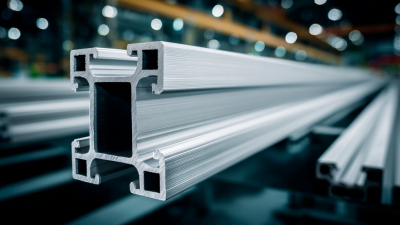

When selecting aluminum profiles for your construction project, several key factors should be considered to ensure the material meets your requirements. Firstly, understanding the mechanical properties of aluminum is essential. According to a report by the Aluminum Association, aluminum profiles offer a high strength-to-weight ratio, making them ideal for various structural applications. The yield strength of commonly used aluminum alloys, such as 6061 and 6063, can range from 35,000 to 40,000 psi, providing adequate support while minimizing overall weight.

Another critical factor is corrosion resistance. Aluminum naturally forms a protective oxide layer that enhances its durability in diverse environments. The International Journal of Advanced Materials Research highlights that anodized aluminum can significantly improve corrosion resistance, which is particularly important in outdoor applications or humid conditions. Therefore, selecting profiles that are anodized or powder-coated can extend the lifespan of your construction elements, reducing maintenance costs over time.

Thermal and electrical conductivity is also vital when choosing aluminum profiles, especially for projects involving electrical systems or thermal management. A study from the Materials Science and Engineering Journal indicates that aluminum has a thermal conductivity of approximately 235 W/m·K, which can aid in heat dissipation. Additionally, its electrical conductivity is about 61% IACS, making it a preferred choice for electrical enclosures and conduits. Assessing these properties will help ensure your chosen aluminum profiles are tailored to the specific needs of your project.

When it comes to construction materials, aluminum profiles have gained significant traction due to their unique benefits over traditional materials. One of the most noteworthy advantages is their exceptional strength-to-weight ratio, which allows for reduced structural load without compromising durability. According to a report by the Aluminum Association, aluminum is about one-third the weight of steel yet can achieve similar structural integrity, making it an ideal choice for large-scale construction projects where weight reduction is critical.

Additionally, aluminum’s resistance to corrosion significantly enhances its longevity in various environmental conditions. The Aluminum Extruders Council noted that aluminum profiles typically last over 40 years in outdoor environments without significant deterioration. This durability translates to lower maintenance costs over time, positioning aluminum as a cost-effective solution in the long run. Moreover, aluminum's recyclability further elevates its sustainability credentials; it can be recycled multiple times without losing quality, supporting the growing demand for green construction practices. This combination of lightweight strength, durability, and sustainability makes aluminum profiles a compelling choice for modern construction projects.

When selecting aluminum construction profiles for your project, ensuring structural integrity and performance is paramount. The first step is to assess the specific loads and stresses that the profiles will encounter. This includes understanding factors such as weight distribution, environmental influences like wind and snow loads, and the expected lifespan of the structure. Utilizing profiles designed with appropriate geometries can significantly enhance strength while reducing material consumption.

Additionally, examining the manufacturing process and material quality is crucial for long-term performance. Look for aluminum alloys that meet industry standards for strength and corrosion resistance. Anodized finishes or coatings can further increase durability, especially in challenging environments. It's also beneficial to consult with engineers or manufacturers to ensure that the selected profiles integrate seamlessly with other project components, promoting overall structural cohesion and safety. Choosing the right aluminum profiles thus relies on a blend of careful planning, materials science, and expert consultation.

This chart displays the comparison of different properties of aluminum profiles such as tensile strength, corrosion resistance, and thermal conductivity, critical for ensuring structural integrity and performance in construction projects.

When sourcing aluminum construction profiles for your project, quality should be your primary concern. Start by identifying reputable suppliers who provide detailed specifications and certifications for their products. Look for profiles that meet industry standards, as this ensures reliability and longevity. Take advantage of online reviews and testimonials from previous clients to gauge a supplier's reputation. Additionally, consider visiting suppliers in person if possible, to inspect their materials and manufacturing processes.

Another key factor is the purchasing process itself. Don’t hesitate to ask about the sourcing practices of your supplier. Inquire about the origin of their aluminum and whether it is recycled or virgin material. Understanding the sustainability aspects can be beneficial not only for ethical considerations but also for potential cost savings. Furthermore, engage your supplier in discussions about customization options to ensure that you receive profiles that precisely meet your project requirements. This proactive approach will not only enhance the quality of your project but also build a strong relationship with your supplier for future needs.