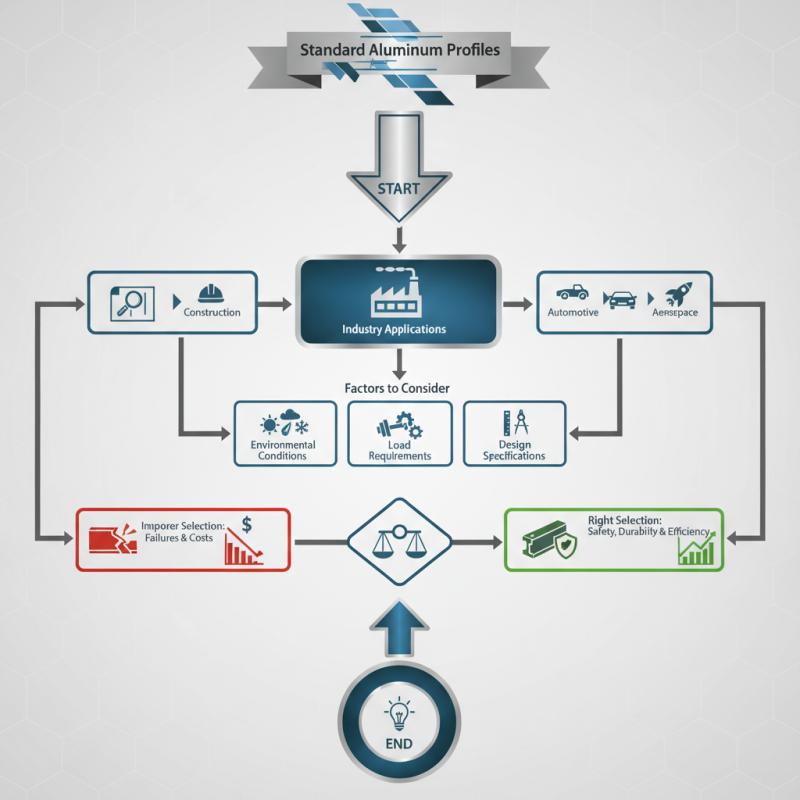

Choosing the right Standard Aluminum Profiles can be a complex task. Industry expert John Smith once said, "Selecting the right profile is crucial for project success." Many factors influence this decision. Understanding your specific needs is essential.

Standard Aluminum Profiles come in various shapes and sizes. Each profile serves a different purpose. Construction, automotive, and aerospace industries often use these materials. However, not all profiles are suitable for every application. It’s vital to assess environmental conditions, load requirements, and design specifications.

Consider the long-term impacts of your selection. Improper profiles can lead to structural failures. Additionally, they may increase costs during installations. Carefully analyzing your project's needs saves time and resources. Reflect on your choices. The right profiles not only enhance functionality but also ensure safety and durability.

When choosing standard aluminum profiles, it's essential to understand the different types available. Extruded profiles are quite common. They are versatile and can be used for various applications. Shapes include T-slots, angles, and channels. Each shape serves a unique purpose. For example, T-slots allow for easy assembly with accessories.

Another option is the anodized aluminum profile. This finishing process adds durability and corrosion resistance. It's ideal for outdoor applications. However, not all anodized profiles are the same. Some may have a thinner layer, which can wear quickly. It's vital to assess the thickness based on your project's needs.

Consider your project's specific requirements. Do you need lightweight structures, or is strength a priority? Sometimes, people overlook the weight-to-strength ratio. This ratio significantly impacts performance. Reflecting on potential errors before making a final choice can save time and resources.

When choosing aluminum profiles, understanding your project requirements is crucial. Consider the intended use. Will they be structural support, aesthetic elements, or a combination of both? Different applications demand different strengths and finishes. Identify the weight load, length, and bending characteristics needed for your design.

Next, think about compatibility. Will the profiles connect with other materials? For example, wood or glass? It's essential to choose profiles that work seamlessly with your chosen components. Sometimes, you may discover that a standard profile doesn't meet your needs. That's okay. Be open to modifying specifications or adjusting designs. Don't rush this process; it can lead to costly mistakes later.

Lastly, consider the environment. Is the installation area exposed to weather conditions or chemicals? This can impact the durability you need. Choosing the right alloy or finish is essential. It may feel overwhelming, but it's worth investing time to get it right. Reflect on your options and take the time to choose wisely.

| Dimension | Weight (kg/m) | Material Thickness (mm) | Load Capacity (kg) | Application |

|---|---|---|---|---|

| 20x20 mm | 0.5 | 1.5 | 30 | Frame Structures |

| 30x30 mm | 0.8 | 2.0 | 50 | Machine Guards |

| 40x40 mm | 1.2 | 2.5 | 80 | Conveyor Systems |

| 50x50 mm | 1.6 | 3.0 | 100 | Workstations |

| 60x60 mm | 2.0 | 3.5 | 150 | Industrial Racks |

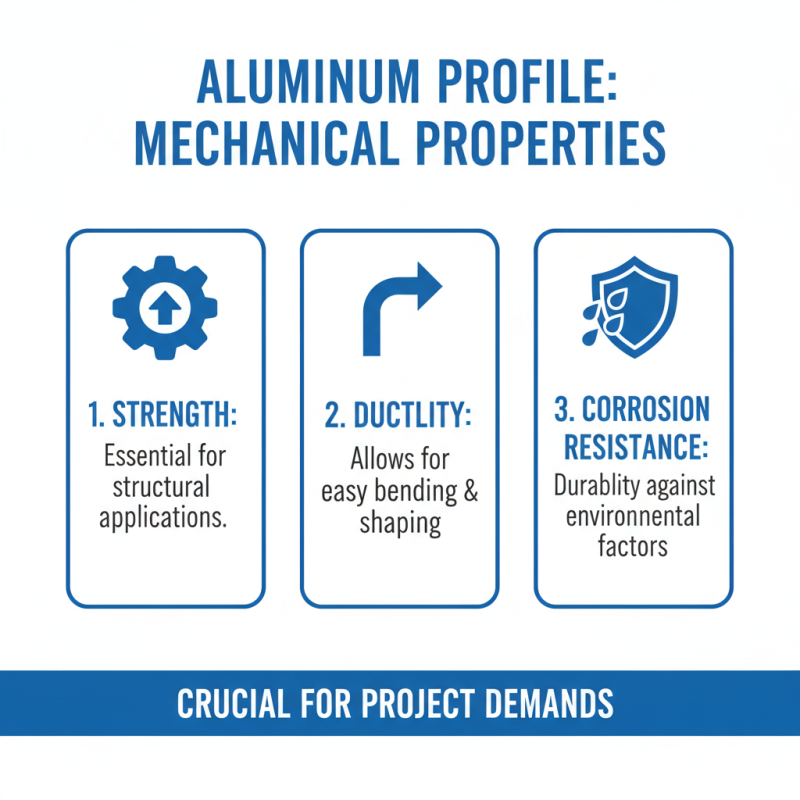

When selecting aluminum profiles, mechanical properties are crucial. These properties include strength, ductility, and corrosion resistance. High strength is essential for structural applications. Ductility allows for easy bending and shaping. Without these qualities, profiles may not meet project demands.

Consider the intended application of the aluminum profile. For instance, thin profiles may not withstand heavy loads well. Conversely, thicker profiles might be unnecessarily heavy. Finding balance is key. You don't want a profile that's too stiff, as it may crack under pressure.

Corrosion resistance is another important factor. Some environments, like coastal areas, can accelerate corrosion. Choosing the right alloy can help mitigate this issue. Reflect on the conditions your profile will face. It's easy to overlook this aspect during selection. Proper evaluation can save future maintenance costs and enhance longevity. Make sure to assess these properties thoroughly before making a decision.

When selecting the right standard aluminum profiles, surface finishes play a crucial role. Anodized, powder-coated, and brushed finishes each offer unique benefits. Anodizing increases corrosion resistance by up to 30%. This is essential for outdoor applications. Powder coating delivers a vibrant aesthetic but may not suit all environments.

Consider the application of each finish. For example, anodized finishes are ideal for industrial and marine uses due to their durability. However, they may not provide the colorful options available with powder coatings. Brushed finishes offer a sleek appearance but are less resistant to wear and corrosion.

**Tip**: Always assess the environment where the aluminum profiles will be used. Wet and salty conditions require finishes with higher corrosion resistance.

Certain industry reports suggest that choosing the correct finish can extend the life of aluminum components. This can lead to cost savings, as replacements are less frequent. Reflect on the long-term implications of your choice before committing. A surface finish is not just cosmetic; it influences performance.

Selecting the right supplier for your aluminum profiles can significantly impact your project's success. Start by researching potential suppliers. Look for companies that have a good reputation in the market. Customer reviews can provide insights into quality and reliability.

Tips: Always request samples before making a bulk order. This helps you assess the quality of the aluminum profiles. Test their customizability to ensure they meet your specific needs. It's also advisable to check their production capabilities.

Another important factor is communication. A supplier should be responsive and open to your suggestions. If their communication is poor, consider it a red flag. You want a partner who values your input and is easy to reach.

Tips: Pay attention to their delivery timeline. Late deliveries can disrupt your project schedule. Lastly, inquire about after-sales service. Good support can provide peace of mind long after the purchase. Remember, choosing the right supplier takes time and careful consideration.