In the evolving landscape of construction and manufacturing, selecting the right manufacturer for Aluminum Profiles has become increasingly essential for achieving optimal solutions. According to a recent industry report by MarketsandMarkets, the global aluminum profile market is projected to reach USD 60.48 billion by 2025, growing at a CAGR of 5.6% from 2020 to 2025. This growth underscores the rising demand for high-quality aluminum products across various sectors, from automotive to architecture. Choosing the right manufacturer not only ensures compliance with stringent quality standards but also enhances operational efficiency and sustainability. Thus, understanding the benefits of different types of Aluminum Profiles and the factors influencing manufacturer selection is crucial for businesses aiming to leverage this versatile material effectively in their projects.

In the evolving landscape of construction and manufacturing, selecting the right manufacturer for Aluminum Profiles has become increasingly essential for achieving optimal solutions. According to a recent industry report by MarketsandMarkets, the global aluminum profile market is projected to reach USD 60.48 billion by 2025, growing at a CAGR of 5.6% from 2020 to 2025. This growth underscores the rising demand for high-quality aluminum products across various sectors, from automotive to architecture. Choosing the right manufacturer not only ensures compliance with stringent quality standards but also enhances operational efficiency and sustainability. Thus, understanding the benefits of different types of Aluminum Profiles and the factors influencing manufacturer selection is crucial for businesses aiming to leverage this versatile material effectively in their projects.

When selecting an aluminum profile manufacturer, understanding the key considerations can lead to optimal solutions for your projects. One of the most significant trends shaping the industry is the shift towards sustainable building materials. With growing awareness of environmental concerns, manufacturers are increasingly adopting innovative production technologies that enhance performance while minimizing ecological impact. Look for manufacturers who prioritize sustainability in their processes, as this reflects a commitment to both quality and environmental responsibility.

Tip: Always assess a manufacturer's certifications and industry standards related to sustainable practices. This can provide insight into their commitment to using eco-friendly materials and processes.

Moreover, the recent geopolitical shifts, including rising tariffs on imports from certain countries, have led to a reevaluation of manufacturing options. It's essential to consider how these trade dynamics may affect the costs and availability of aluminum profiles. By choosing a manufacturer that has adaptable supply chains and local production capabilities, you can mitigate potential disruptions.

Tip: Conduct thorough research on a manufacturer's sourcing strategies and materials supply chain to ensure reliability and cost-effectiveness amidst changing global trade conditions.

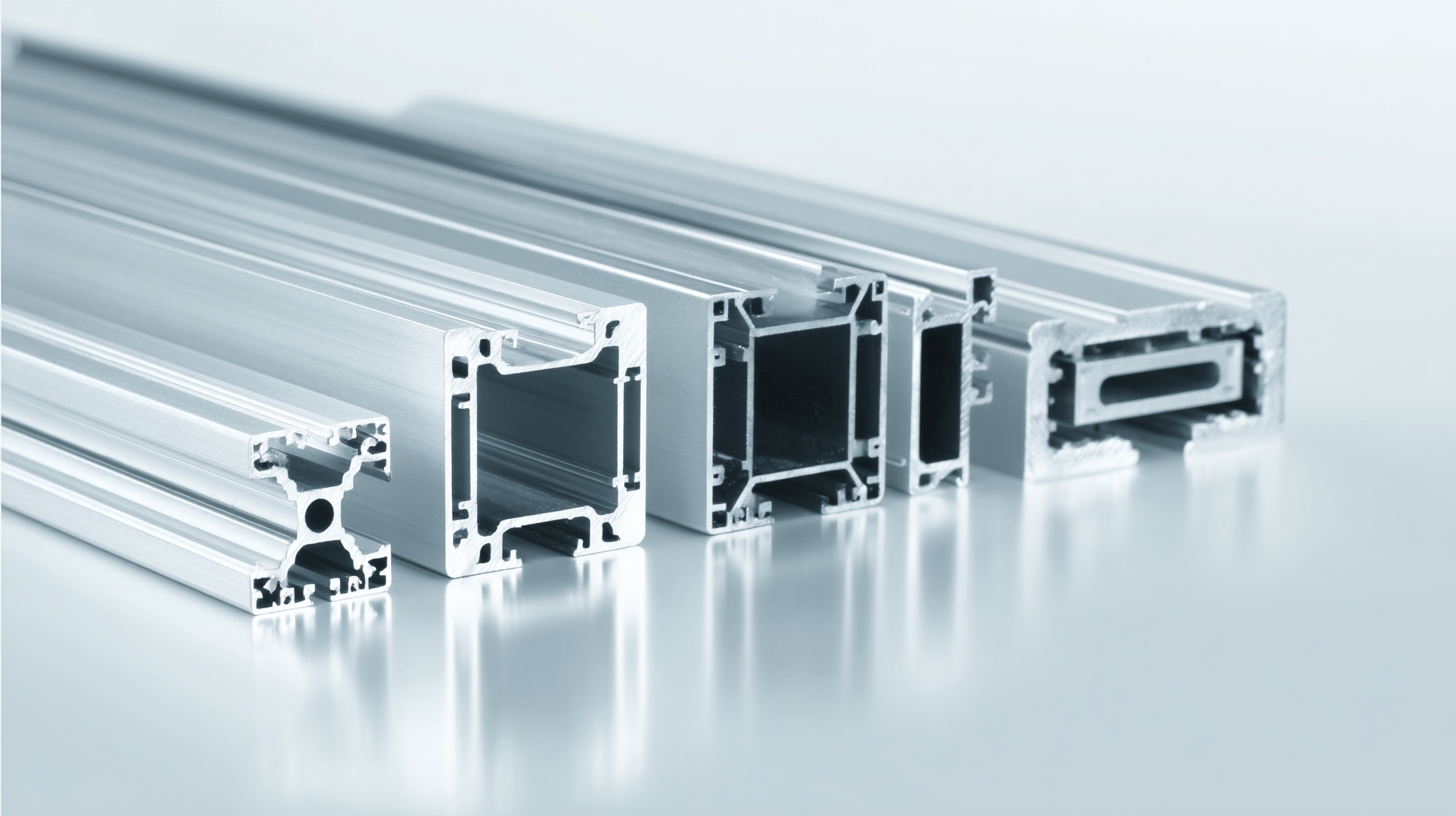

Aluminum profiles are becoming increasingly vital across various industries, including construction and transportation, due to their lightweight nature and strength. The extrusion market, projected to reach USD 11.5 billion by 2026, highlights the expanding role of aluminum in meeting industry demands. These profiles are not only essential for structural applications but also contribute to energy efficiency and sustainability in construction projects. With a significant 10% rise in the nominal value added in the construction industry in 2024, the demand for high-performance aluminum solutions is set to continue surging.

In the automotive sector, the trend towards advanced lightweight materials is reshaping vehicle design and manufacturing. A comprehensive review of lightweight materials identifies aluminum as a key player, with applications that enhance fuel efficiency and reduce emissions. As automobile manufacturers prioritize sustainability, the incorporation of aluminum profiles can lead to substantial weight savings—crucial for meeting evolving regulatory standards and consumer expectations. Furthermore, the global aluminum recycling market, anticipated to grow from USD 111.61 billion in 2024 to USD 138.17 billion by 2033, underscores the importance of recycling aluminum profiles, thereby supporting a circular economy and minimizing environmental impact.

In the aluminum profile production industry, quality control plays a pivotal role in determining the final product's efficacy and reliability. According to a report by Smithers Pira, nearly 60% of manufacturers face challenges related to quality assurance during production. Common issues include inconsistencies in material properties and defects such as surface imperfections, which can significantly impact performance. Implementing robust quality control protocols through real-time monitoring and advanced testing methods is crucial for manufacturers to reduce waste and meet industry standards.

Recycling challenges also pose significant hurdles. With aluminum being infinitely recyclable, the potential environmental benefit is substantial. However, the recycling process often faces obstacles, including contamination and the degradation of material properties. A study from the Aluminum Association indicates that up to 25% of recycled aluminum profiles are lost due to inadequate sorting and processing methods. To harness the full potential of aluminum recycling, manufacturers must invest in improved separation technologies and educate stakeholders on the importance of maintaining material integrity throughout the recycling chain. Addressing these issues can lead to higher quality outputs and a more sustainable production cycle.

When choosing the right manufacturer for aluminum profiles, evaluating their capabilities is crucial for achieving optimal solutions. Key factors such as certifications, advanced technologies, and customer feedback should guide your decision-making process. For instance, certifications like CMMI Level 5 demonstrate a manufacturer’s commitment to quality and operational excellence. Industry reports highlight that companies with high certifications tend to have a more robust system for managing projects, thereby reducing delivery times and increasing customer satisfaction.

Additionally, leveraging innovative technologies is essential for staying competitive. Reports from market analyses show that companies investing in advanced production technologies experience a significant increase in efficiency and reduction in costs. In the realm of digital transformation, this is particularly important, as businesses that implement digital tools can enhance customer interaction, thereby elevating the overall experience.

**Tips:**

- Always check for relevant certifications as they reflect a manufacturer’s adherence to industry standards.

- Seek out detailed customer feedback to gauge satisfaction and reliability.

- Analyze a manufacturer’s technological investments to ensure they are equipped to meet contemporary needs while maintaining quality.

The aluminum profiles market is experiencing significant shifts driven by innovations and sustainability efforts. Manufacturers are increasingly integrating advanced technologies to enhance the performance and aesthetic appeal of aluminum profiles. This trend not only meets the rising consumer demand for high-quality products but also aligns with global sustainability initiatives. Companies are exploring new alloys and fabrication processes that reduce waste and energy consumption, reinforcing the industry's commitment to environmental stewardship.

**Tip:** When selecting a manufacturer, prioritize those who showcase a clear sustainability strategy. Consider their use of recycled materials and energy-efficient production practices, as these factors contribute to reducing the overall carbon footprint of your projects.

Moreover, the growing emphasis on sustainable products is prompting manufacturers to commit to eco-friendly certifications and practices. This includes adopting life cycle assessment approaches to evaluate the environmental impact from production to disposal. As companies innovate, they are also focusing on the longevity and recyclability of aluminum profiles, making them an attractive choice for eco-conscious consumers.

**Tip:** Stay informed about the latest market trends and innovations by attending industry expos and webinars. Networking with professionals can provide valuable insights into which manufacturers lead in sustainability and innovation.

| Dimension | Market Share (%) | Recent Innovations | Sustainability Efforts | Growth Rate (2023) |

|---|---|---|---|---|

| Structural Profiles | 35% | Lightweight Solutions with Enhanced Strength | Recyclable Materials Usage | 5% |

| Architectural Profiles | 25% | Customizable Designs for Aesthetic Appeal | Energy-Efficient Coatings | 6% |

| Industrial Profiles | 20% | Automation Compatibility Features | Reduced Carbon Footprint Manufacturing | 4% |

| Transportation Profiles | 10% | Integration of Smart Technology | Use of Sustainable Resource Materials | 5% |

| Consumer Goods Profiles | 10% | Innovative Packaging Solutions | Zero-Waste Production Processes | 7% |