In recent years, the demand for Aluminum Profiles has surged, driven by their versatility and lightweight properties, making them essential components in various industries, including construction, automotive, and aerospace. According to a report by Research and Markets, the global aluminum market is projected to grow significantly, driven by the rising consumption of aluminum products, which is anticipated to reach approximately 86 million metric tons by 2026. This growth underscores the importance of selecting the right Aluminum Profiles tailored to specific project needs. As industries increasingly prioritize sustainable materials, understanding the different types of aluminum profiles, their applications, and performance characteristics becomes crucial for optimizing functionality and efficiency in design and construction projects. In this guide, we will explore essential factors to consider while choosing Aluminum Profiles that align with your project requirements.

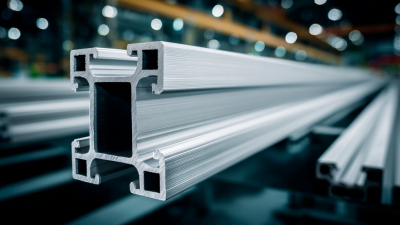

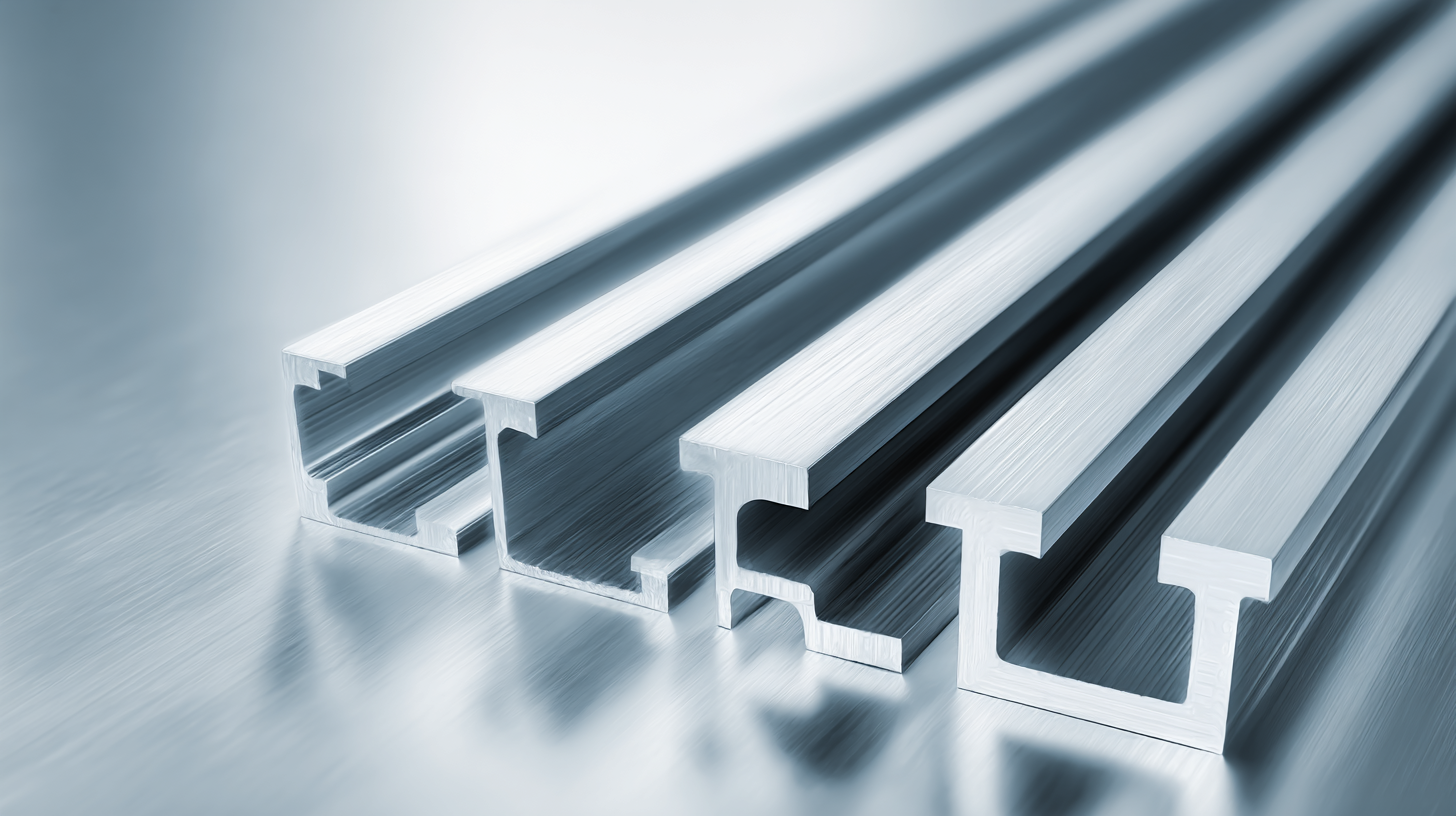

When it comes to selecting the right aluminum profiles for your project, understanding the various types available is crucial. Aluminum profiles are categorized into several types, including standard shapes, custom shapes, and structural profiles. According to a report by Research and Markets, the global aluminum extrusion market is projected to reach $106.6 billion by 2029, driven by increasing applications in construction, automotive, and consumer goods. This underscores the significance of choosing the suitable type of profile to meet specific project needs, whether it’s for frames, supports, or aesthetic elements.

Standard aluminum profiles, like 6063 and 6061, are commonly used due to their excellent mechanical properties and corrosion resistance. The 6063 aluminum is especially favored for architectural applications, offering effective thermal insulation and malleability, making it easier to adapt to various designs. In contrast, 6061 is preferred for structural applications, thanks to its high strength-to-weight ratio. Data from Grand View Research indicates that the demand for these profiles is expected to grow significantly, highlighting the increasing importance of selecting the right type of aluminum profile based on the specific application requirements. Understanding these distinctions is essential for optimizing functionality and achieving desired outcomes in your project.

When selecting aluminum profiles for your project, several key factors should guide your decision-making process. First, consider the specific application and load-bearing requirements of your project. Different profiles are designed to withstand varying levels of stress and load; therefore, understanding the mechanical demands is crucial. Additionally, the environmental conditions the profiles will face should be evaluated, such as exposure to moisture, chemicals, or extreme temperatures, as these factors can affect the longevity and performance of aluminum.

Another important aspect to consider is the profile's finish and aesthetic appeal. Depending on the project's purpose, you may require a specific coating or surface treatment that enhances both durability and visual integration with the overall design. Furthermore, compatibility with existing components and ease of fabrication should also be examined to ensure a seamless assembly process. Taking the time to analyze these factors will ultimately lead to a more effective selection of the right aluminum profiles for your project.

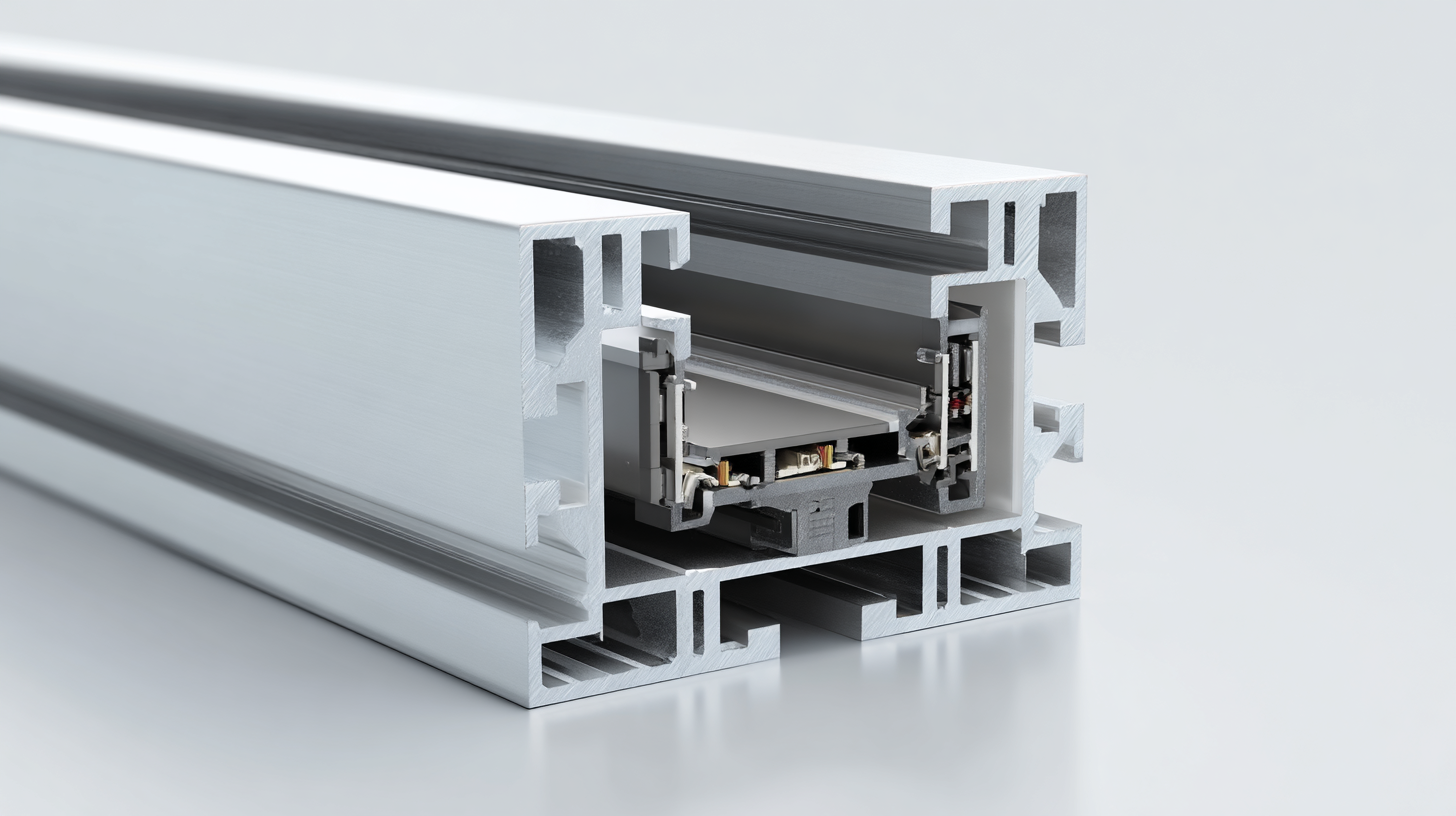

When selecting aluminum profiles for structural applications, understanding their load-bearing capacities is crucial. The strength-to-weight ratio of aluminum, which is approximately 3:1 compared to steel, makes it an excellent choice for many engineering projects. According to the Aluminum Association, specific alloy grades such as 6061 and 6063 demonstrate varying yield strengths, with 6061 offering a yield strength of around 40,000 psi, making it suitable for heavier loads, while 6063, with a yield strength of about 27,000 psi, is often used in architectural applications.

It's essential to analyze the moment of inertia and section modulus of the profiles being considered. For instance, a common approach in structural design involves calculating the maximum allowable load based on the specific profile geometry and the anticipated application. A study by the American Institute of Steel Construction (AISC) indicates that the addition of thicker walls to aluminum profiles can significantly enhance their load-bearing capabilities while maintaining a lighter overall weight. This adaptability allows designers to optimize both performance and cost-effectiveness in their projects.

When selecting aluminum profiles for your project, the finish and coating options available are crucial for enhancing performance and durability. The surface treatment not only improves the aesthetic appeal but also provides essential protective qualities against environmental factors. Anodizing, for example, is a popular choice as it increases corrosion resistance and contributes to a longer lifespan, making it suitable for both indoor and outdoor applications.

Tips: When choosing a finish, consider the specific environment your aluminum profiles will face. For coastal areas with high humidity, opting for a marine-grade anodized finish can offer additional protection. Likewise, a powder coating can provide a robust layer of color and durability, effectively resisting scratches and UV damage.

Furthermore, it's important to note that different coatings may affect thermal and electrical conductivity. If your project involves electrical components, selecting the right finish that maintains conductivity while providing protection is key. Always assess the functional requirements alongside aesthetic preferences to ensure the chosen aluminum profiles align with your project needs effectively.

When selecting aluminum profiles for your projects, it's crucial to prioritize sourcing and sustainability. Start by researching suppliers who not only provide a variety of aluminum profiles but also implement eco-friendly practices. Look for companies that utilize recycled materials in their production processes, as this significantly reduces the carbon footprint associated with manufacturing. Evaluate the supplier's commitment to sustainability by checking their certifications and adherence to environmental regulations.

In addition to sustainability, assess the reliability and quality of potential suppliers. It's advisable to read reviews and seek recommendations from other customers. Opt for suppliers who have a transparent manufacturing process and provide detailed specifications about their products. This not only ensures that you receive high-quality aluminum profiles aligned with your project needs but also fosters a partnership with companies that value ethical practices. By combining these evaluations, you can make informed decisions that support both your project goals and sustainable development.