When it comes to selecting the right materials for architectural projects, one cannot overlook the significance of Architectural Aluminum Profiles. According to a recent report by the Freedonia Group, the demand for aluminum in construction is projected to grow by over 5% annually, driven by its lightweight properties, durability, and aesthetic appeal. These profiles have become a staple in modern architecture, offering versatility for a wide range of applications from window frames to structural components.

Aluminum profiles have become a cornerstone in modern architecture, offering both functionality and aesthetic appeal. According to a recent report by ResearchAndMarkets, the global aluminum extrusion market is expected to reach $82 billion by 2026, driven largely by the construction sector. Architects increasingly favor aluminum for its lightweight properties, which can significantly reduce structural loads and enable innovative designs. This versatility allows for a wide range of applications, from window frames to complex façade systems, making it an essential material in contemporary buildings.

Moreover, aluminum profiles are renowned for their durability and sustainability. A study by the Aluminum Association highlights that aluminum can be recycled indefinitely without loss of quality, making it a greener choice compared to other materials. In fact, recycled aluminum saves up to 95% of the energy required to produce new aluminum. This aligns with the growing demand for eco-friendly construction practices, reinforcing the significance of aluminum profiles as not just a practical option but also a responsible one. As we move towards more sustainable architectural solutions, the choice of aluminum profiles becomes increasingly crucial in shaping the built environment.

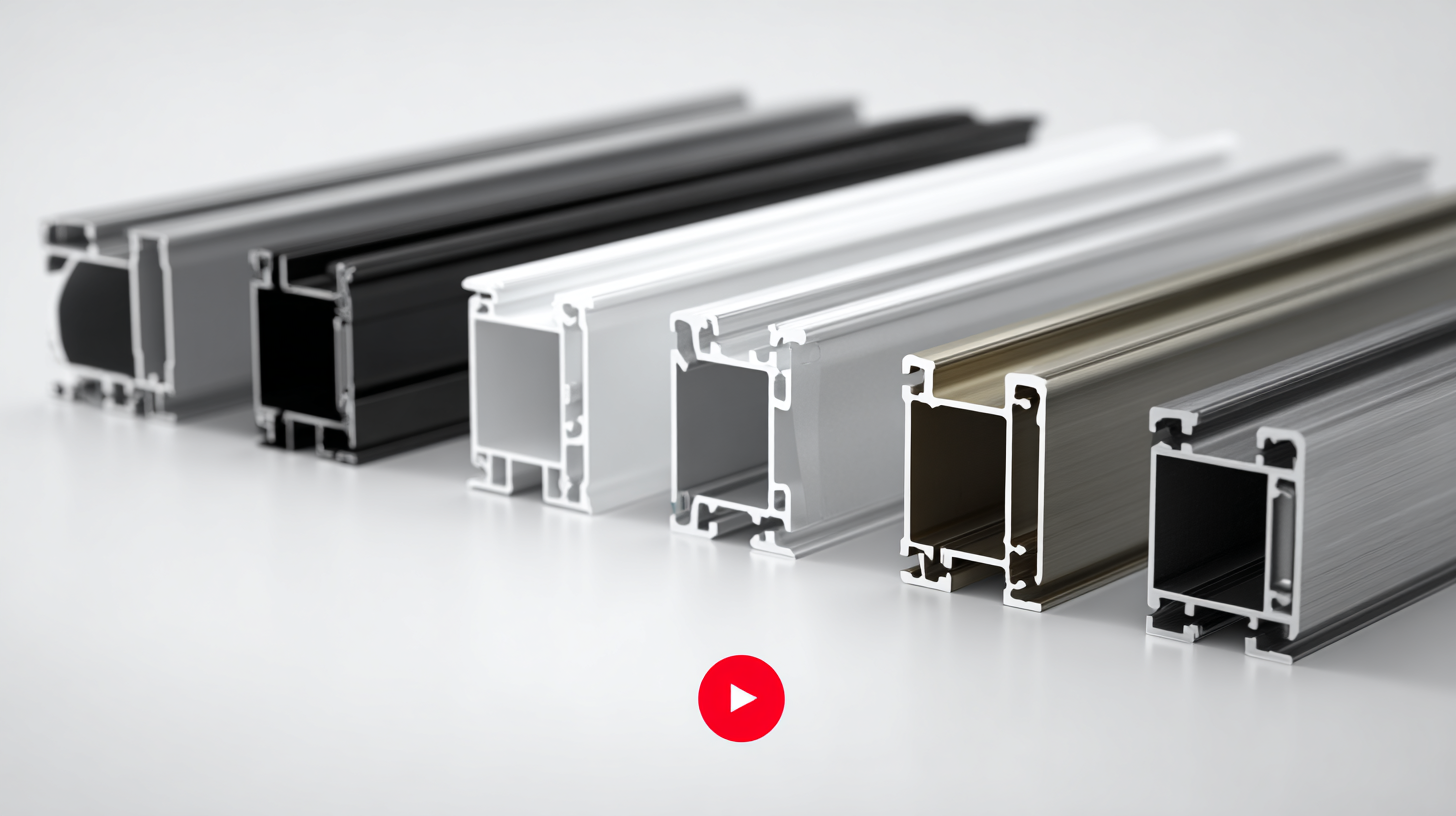

When selecting architectural aluminum profiles for your next project, several key factors should be considered to ensure optimal performance and aesthetics. One of the most critical aspects is the profile's strength and durability. According to a report from the Aluminum Association, aluminum has a strength-to-weight ratio that can be up to three times greater than that of steel, making it an excellent choice for structural applications while remaining lightweight. This characteristic is particularly beneficial in large-scale projects where weight constraints are paramount.

Another essential factor is the type of alloy used in the aluminum profiles. For instance, Aluminum 6061 and 6063 are among the most commonly used alloys in architectural applications due to their excellent corrosion resistance and formability. A study by the American Society for Testing and Materials (ASTM) highlights that these alloys maintain their integrity even in harsh environmental conditions, ensuring long-term performance. Additionally, considering the finishing options, such as anodizing or powder coating, can enhance aesthetic appeal while providing further protection against wear and tear. By carefully evaluating these factors, architects can make informed decisions that align with both functional requirements and design intentions.

When selecting architectural aluminum profiles for your next project, it's crucial to evaluate potential suppliers carefully. One of the primary factors to consider is their adherence to industry certifications and standards. Reputable suppliers often comply with international standards such as ISO 9001 for quality management systems and ASTM for material specifications. These certifications not only ensure that the products meet specific quality criteria but also reflect the supplier's commitment to maintaining high production practices.

In addition to certifications, assessing a supplier's experience in the industry can provide valuable insights into their reliability and product offerings. Look for suppliers that are well-versed in local building codes and sustainability standards, such as LEED certification. This knowledge indicates that they are equipped to meet the unique requirements of your project while providing materials that are both functional and environmentally friendly. Choosing suppliers with a solid foundation in industry standards and a reputation for quality can significantly enhance the success of your architectural endeavors.

When selecting architectural aluminum profiles for your next project,

understanding the nuances of different aluminum alloys is crucial. Recent research highlights the

advantages of aerospace-grade alloys, such as

7075, known for their superior strength-to-weight ratio and corrosion resistance.

The study on sustainable recycling of aluminum scraps to produce 7075 aluminum sheets

indicates a significant advancement in both performance and environmental sustainability, making it an

excellent choice for high-performance applications.

Tips for choosing the right aluminum alloy:

When selecting architectural aluminum profiles for your next project, ensuring long-term performance and durability is crucial. According to a report by the Aluminum Association, properly chosen aluminum profiles can offer up to 30 years of service life when treated and maintained correctly. This longevity is largely attributed to the material's inherent resistance to corrosion, especially when anodized or coated with protective finishes. Such coatings not only enhance aesthetic appeal but also significantly increase the profile’s ability to withstand harsh weather conditions, making them ideal for various architectural applications.

Moreover, it is essential to consider the thermal efficiency of aluminum profiles. Research from the American Architectural Manufacturers Association indicates that aluminum frames, when equipped with thermal breaks, can reduce heat transfer by up to 60%. This not only contributes to energy savings but also minimizes the risk of condensation, which can lead to mold growth and structural damage over time. Therefore, investing in high-quality, thermally efficient aluminum profiles is a key factor in ensuring the long-lasting performance of your architectural projects.