In the ever-evolving landscape of manufacturing and construction, selecting the right materials plays a pivotal role in the success of any project. Among these materials, Channel Aluminum Extrusion Profiles have gained significant traction due to their lightweight nature, durability, and versatility. According to a report by Research and Markets, the global aluminum extrusion market is projected to reach $60 billion by 2026, with channel profiles presenting a key segment in numerous applications from architectural structures to automotive components. As industries increasingly prioritize sustainability and efficiency, understanding the specific requirements of your project becomes critical. This guide aims to provide insights into how to choose the right Channel Aluminum Extrusion Profiles, ensuring you make informed decisions that align with your project goals and industry standards.

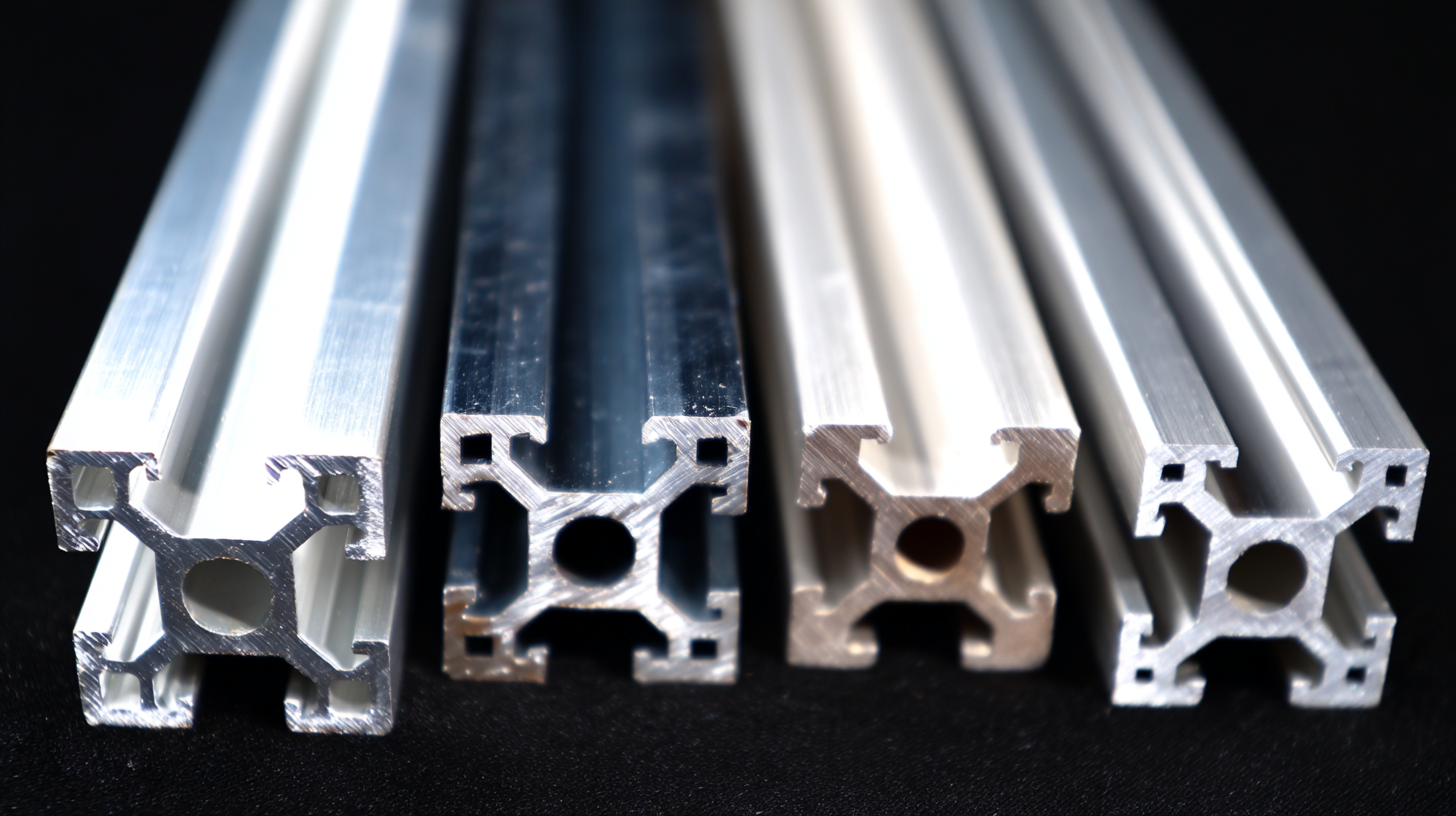

When choosing the right channel aluminum extrusion profiles for your project, it is crucial to understand the various types available in the market. Channel profiles can significantly vary in shape, size, and application. Common types include U-shaped, angle, and T-shaped profiles, each designed to fulfill specific structural and aesthetic needs. The aluminum extrusion market is projected to witness substantial growth, with the global building profile extrusion die market expected to experience sustainable growth over the coming years. As of 2024, the market size for aluminum composite panels is estimated at USD 7.5 billion, reflecting the increasing demand in various sectors, including construction and automotive.

In addition to the structural benefits, the versatility of channel aluminum extrusion profiles is evident across multiple industries. The automotive sector, for instance, is seeing a rising preference for aluminum components due to their lightweight and corrosion-resistant properties. The automotive door hinge market is a prime example, where the selection of appropriate aluminum profiles can lead to improved performance and longevity. Moreover, industry reports indicate that the global window and door frame market is projected to grow at a CAGR of 3.6%, indicating a growing trend towards using advanced materials such as aluminum for improved durability and design flexibility. When selecting channel aluminum profiles, understanding these trends and types will ensure your project’s success.

| Profile Type | Dimensions (mm) | Weight (kg/m) | Strength (MPa) | Common Applications |

|---|---|---|---|---|

| Standard Channel | 50 x 25 | 1.15 | 210 | Frames, Supports |

| Heavy Duty Channel | 100 x 50 | 2.50 | 250 | Structural Components |

| Mini Channel | 25 x 12 | 0.45 | 180 | Small Enclosures |

| Cantilever Channel | 75 x 45 | 1.75 | 210 | Shelf Supports |

| Louver Channel | 60 x 30 | 1.20 | 200 | Ventilation Systems |

When selecting the right channel aluminum extrusion profiles for specific applications, several key factors come into play that can significantly affect the performance, aesthetics, and durability of the final product. First, the load-bearing capacity is crucial; for instance, structures in commercial construction often require profiles that can support significant weight without deformation. According to a report by the Aluminum Association, aluminum has an impressive strength-to-weight ratio, making it ideal for applications where weight savings are critical without compromising structural integrity.

In addition to the mechanical properties, environmental considerations also play a vital role. Profiles intended for outdoor or corrosive environments should be chosen with appropriate finishes or coatings to enhance longevity. The latest industry data suggests that anodized aluminum can increase corrosion resistance by up to 25%, making it suitable for marine or industrial applications where exposure to harsh conditions is frequent. Ultimately, understanding the specific demands of your project, including load requirements, environmental factors, and aesthetic preferences, will guide you in selecting the most suitable channel aluminum extrusion profile.

When selecting channel aluminum extrusion profiles for your project, understanding the mechanical properties and performance metrics is crucial. The structural integrity of the profiles primarily depends on their tensile strength, yield strength, and elasticity. These properties determine how well the aluminum can bear loads without deforming under stress, making them essential considerations for applications that require durability and resilience.

In addition to strength characteristics, performance metrics such as corrosion resistance and thermal conductivity play a significant role in the materials' practical uses. Channel aluminum profiles often undergo various environmental conditions, so selecting alloys with high corrosion resistance can extend the lifespan of the construction. Moreover, understanding how well the material conducts heat is essential in applications that involve thermal management. By analyzing these mechanical properties and performance metrics, you can make informed decisions that will enhance the functionality and longevity of your project.

When embarking on a project that requires channel aluminum extrusions, one of the key factors to consider is budgeting. The cost of aluminum extrusions can vary significantly based on several factors, including the complexity of the design, the type of alloy used, and the volume ordered. To make an informed choice, it's crucial to analyze your project's specific needs and how they align with these cost factors. Understanding the price per pound for different alloys can help you determine which option offers the best performance-to-cost ratio for your application.

Moreover, it's essential to factor in not just the initial purchase price of the extrusions, but also any additional costs that may arise during fabrication and assembly. This includes machining, finishing, and any necessary fabrication equipment. By getting detailed quotes from suppliers and comparing different manufacturers, you can uncover potential savings. Additionally, consider the long-term value of the profiles you choose; investing slightly more upfront for a higher-quality extrusion may lead to reduced maintenance costs and a longer lifespan for your project. Balancing upfront costs with overall value will help ensure that your project stays within budget while meeting all performance specifications.

Aluminum extrusions have gained significant attention for their sustainability and minimal environmental impact in manufacturing. According to the Aluminum Association, aluminum is 100% recyclable without loss of quality, making it a prime candidate for sustainable manufacturing practices. In fact, approximately 75% of all aluminum ever produced is still in use today, demonstrating its longevity and recyclability. This characteristic not only reduces waste in landfills but also cuts down on the energy required for new aluminum production, an area highlighted in the 2021 IAI report showing that recycling aluminum saves up to 90% of the energy compared to virgin material extraction.

Moreover, the use of aluminum extrusions in product designs can contribute positively to overall energy efficiency. The lightweight nature of aluminum can lead to reduced energy consumption in transportation and logistics, further lowering the carbon footprint associated with a product's lifecycle. A study by the International Aluminium Institute in 2020 revealed that using aluminum in construction applications can lead to an overall reduction in greenhouse gas emissions, making it a more environmentally friendly option compared to traditional materials like steel and plastic. With such compelling data, integrating aluminum extrusions into projects not only meets modern sustainability standards but also fosters a commitment to environmentally responsible manufacturing practices.