When tackling a project that requires Aluminum Moulding Profiles, choosing the right type is crucial. Expert consultant Dr. Emily Carter emphasizes, "The right profile can make or break your design." This statement perfectly encapsulates the importance of careful selection in the aluminum moulding industry.

Different projects demand varied specifications. Not every aluminum profile suits your needs. For instance, a decorative profile may enhance aesthetic appeal but might lack structural integrity. Consider the balance between beauty and function. It's essential to reflect on the intended use of the profile. Will it face external elements? Or will it support heavy loads?

Every choice comes with its challenges. The vast array of options can be overwhelming. Some profiles may not be readily available, creating delays. Others might be cost-prohibitive. Therefore, knowing your project's specific requirements and constraints is vital. Take the time to evaluate and consult with professionals who understand the nuances of Aluminum Moulding Profiles. This decision shapes your project's success.

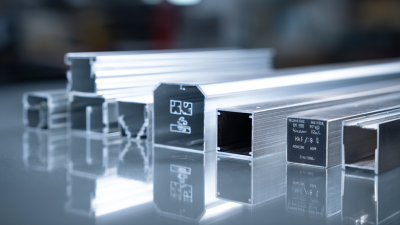

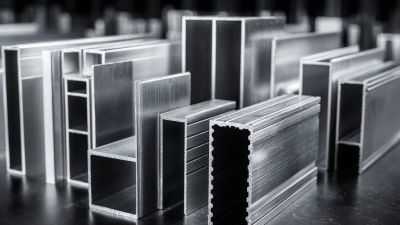

When choosing aluminum moulding profiles, it’s crucial to understand the basics. Aluminum profiles come in various shapes and sizes. Common types include angles, channels, and flat bars. Each shape has distinct applications. A study from the Aluminum Association reported that the demand for aluminum in construction has increased by 20% over the past five years. This reflects its growing importance in various projects.

The thickness of the profile is often overlooked. It can significantly affect durability and functionality. For structural applications, a thicker profile is often necessary. On the other hand, decorative purposes may require thinner options. A report by Research and Markets indicates that up to 40% of consumers prioritize aesthetics over structural strength when selecting aluminum profiles. Understanding the application's requirements is essential to avoid regrettable design decisions later.

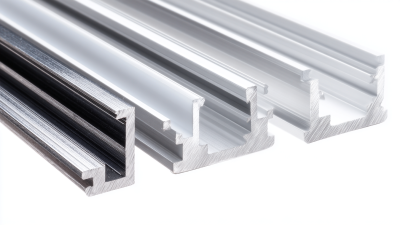

Selecting the right profile also involves considering the finish. Anodized finishes improve corrosion resistance. However, they may not suit every project. Proper research is necessary to avoid mismatches. Mistakes in profile selection could lead to higher costs and wasted time. Reflect on the needs of your project. Evaluate the functional and aesthetic aspects closely to avoid pitfalls.

| Profile Type | Dimensions (mm) | Weight (kg/m) | Applications | Finish Options |

|---|---|---|---|---|

| Corner Bracket | 30x30 | 2.5 | Frame support | Anodized, Powder Coated |

| U-Channel | 50x20 | 1.8 | Wall partition, Signage | Anodized, Mill Finish |

| T-Slot Extrusion | 40x40 | 3.2 | Modular frames, Tool racks | Powder Coated, Anodized |

| Flat Bar | 10x50 | 1.0 | Structural support | Mill Finish, Anodized |

| Angle Profile | 25x25 | 1.5 | Corner reinforcement | Powder Coated, Mill Finish |

When identifying your project's specific requirements, consider the intended application of aluminum moulding profiles. Is it for structural support or decorative purposes? Structural applications may need profiles with higher load-bearing capacities, while decorative ones may prioritize aesthetics. According to recent industry reports, about 40% of design failures stem from misjudging these requirements.

Next, evaluate the environmental conditions that the moulding will be exposed to. For instance, if the profiles will be used outdoors, they should resist corrosion and weathering. Statistics show that aluminum profiles can last more than 50 years in coastal environments when properly treated. However, choosing inadequate profiles could lead to premature degradation and costly repairs.

It’s essential to analyze available dimensions and customizations. Many projects face compatibility issues due to non-standard dimensions. One study indicates that 25% of construction delays are linked to improperly chosen profiles. Balancing aesthetics and functionality can be challenging. Perfecting this choice often requires testing and iterative adjustments. This may require extra time but ultimately leads to better outcomes.

This chart illustrates the common types of aluminum moulding profiles and their suitability for various project requirements, such as residential, commercial, and industrial applications.

When evaluating different types of aluminum moulding profiles, it's essential to focus on their specific features. Various profiles serve varied purposes in construction and design. For instance, flat bars offer simplicity, making them suitable for straightforward applications, while angles provide robust structural support. Choosing the right profile can significantly impact your project’s outcome.

Consider the environment where the moulding will be used. Some profiles resist corrosion better than others. Additionally, think about aesthetics; the finish can enhance or detract from your design vision. A polished look may be ideal for modern spaces, while a brushed finish suits industrial styles. Be honest about your project's needs and limitations. Sometimes, the most suitable profile isn’t the flashiest. It can be easy to overlook practical concerns for visual appeal, so take your time to reflect on what truly fits. The right choice should combine functionality and beauty.

When choosing aluminum moulding profiles, consider both aesthetics and functionality. The right profile can elevate your project. For a clean look, opt for sleek designs with smooth finishes. This choice enhances modern spaces, creating a sense of harmony. However, striking a balance between style and utility is crucial. Sometimes, visually appealing profiles may lack strength. Test them in real-life scenarios.

Tips: Pay attention to color and texture. Different finishes can drastically change the character of a space. Consider how the light interacts with the profile. A brushed surface may cast interesting shadows, enhancing depth.

Functionality matters as much as looks. Profiles should withstand wear and mechanical stress. Check weight ratings to ensure durability. Less attractive choices might offer better performance for your specific needs. Don't shy away from bold, unique designs, but remember they should serve their purpose effectively.

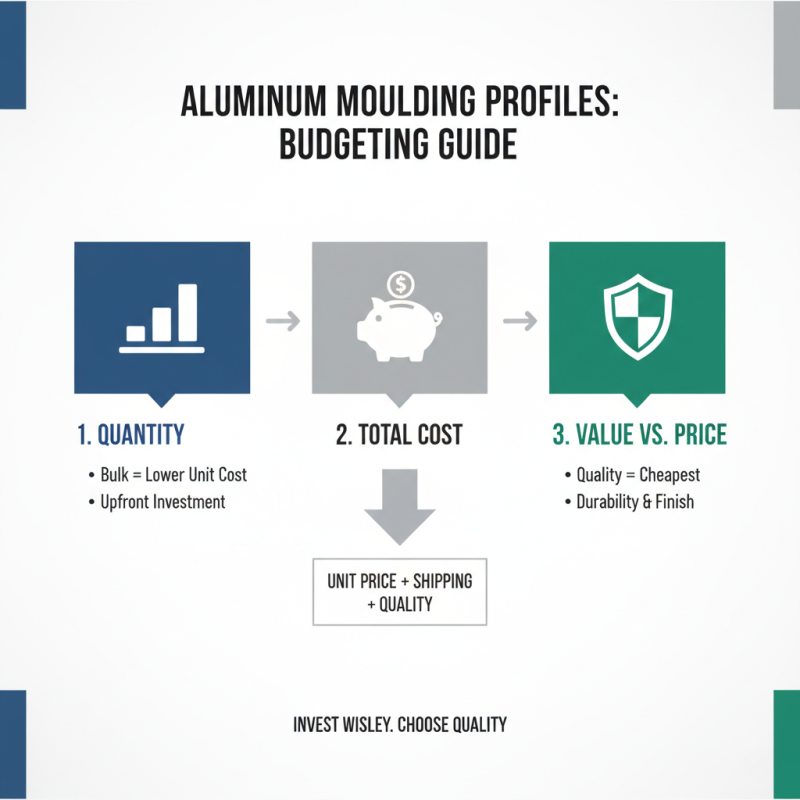

When budgeting for aluminum moulding profiles, it’s essential to evaluate all potential costs. Start with the quantity you need. Larger quantities might reduce the unit price but require upfront investment. Keep in mind that the cheapest option isn't always the best. Quality often reflects in the price.

Tip: Always request samples before making a bulk purchase. This ensures you understand the look and feel of the product. Testing samples in your project environment can prevent future headaches.

Sourcing quality materials can be a challenge. Not all suppliers offer the same level of service or product standards. Look for reviews or ask for recommendations. Sometimes, good deals come from lesser-known sources.

Tip: Visit local supply stores to compare options. You may find unexpected gems that fit into your budget. Always count hidden costs like transportation and potential waste in your calculations. Trust your instincts but remain open to revisiting your choices if needed.