The choice of the right Standard Aluminum Profiles for your projects is crucial in achieving the desired performance and durability while maintaining cost-effectiveness. According to a report by the Aluminum Association, the demand for aluminum in construction and industrial applications is projected to grow by 3.2% annually, highlighting the increasing reliance on this versatile material. Standard Aluminum Profiles, known for their strength-to-weight ratio, corrosion resistance, and recyclability, are becoming increasingly popular across various sectors, including architecture, manufacturing, and transportation.

When selecting Standard Aluminum Profiles, it is essential to consider factors such as material grade, dimensions, and specific application requirements. A study conducted by MarketsandMarkets indicates that the global aluminum extrusion market is expected to reach USD 70 billion by 2026, fueled by the growing adoption of aluminum profiles in building and construction projects. As industries continue to innovate and evolve, the ability to choose the most suitable Standard Aluminum Profiles will significantly impact project efficiency, structural integrity, and overall sustainability. Therefore, understanding the diverse options available and their respective benefits is imperative for professionals seeking to enhance their project outcomes.

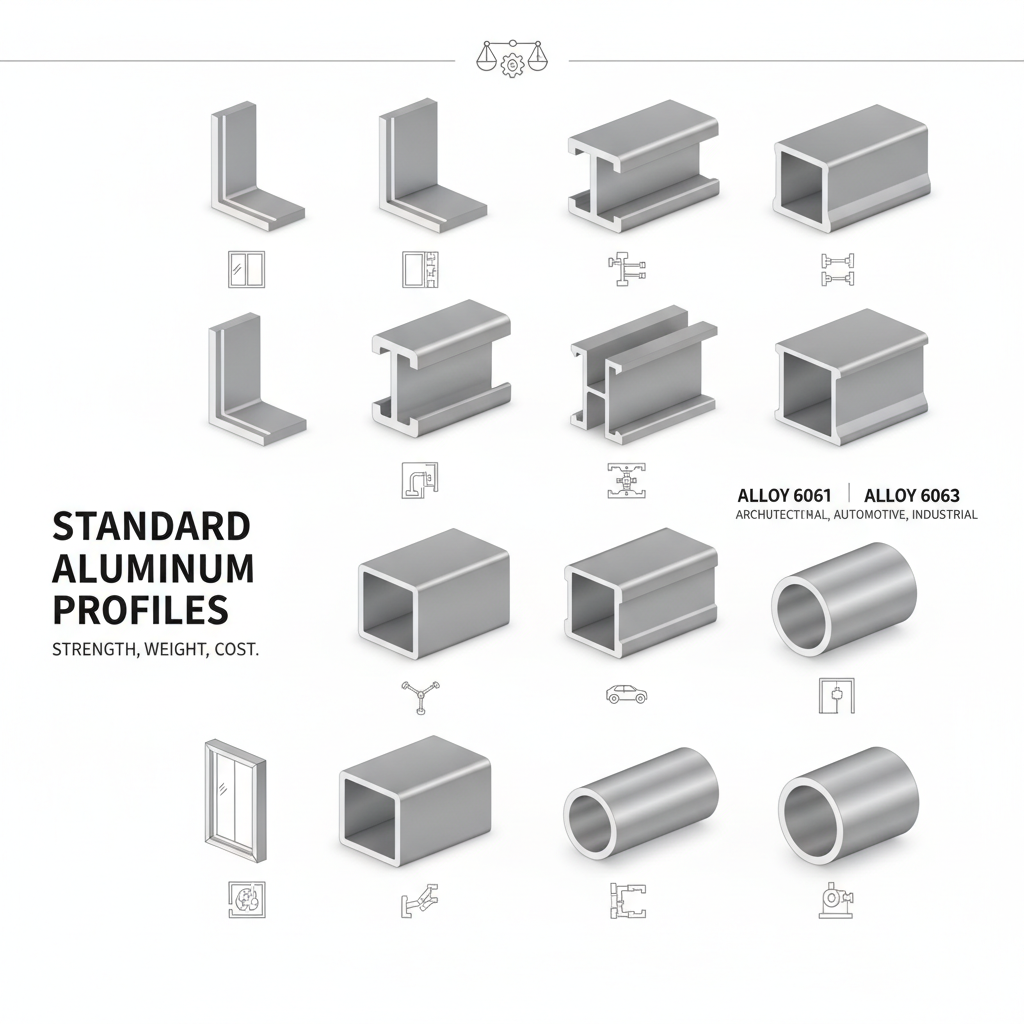

Understanding standard aluminum profiles and their applications is crucial for selecting the right materials for your projects. Standard aluminum profiles are pre-fabricated shapes and sizes that are widely used in construction, manufacturing, and design industries. They offer versatility and strength, making them suitable for various applications, from creating structural frameworks to crafting detailed designs. Knowing the different types of profiles available, such as extruded shapes, channels, and angles, can help you make informed decisions tailored to your specific needs.

When working on projects, consider the desired strength, weight, and corrosion resistance of the aluminum profiles. For instance, certain profiles are better suited for lightweight structures, while others provide enhanced durability for more demanding applications. Additionally, the ease of assembly and integration with other components is a vital factor. By understanding the properties and uses of standard aluminum profiles, you can optimize your project outcomes and ensure efficiency in your design processes.

| Profile Type | Weight (kg/m) | Typical Applications | Common Dimensions (mm) | Material Grade |

|---|---|---|---|---|

| Square Tube | 1.5 | Frameworks, structural support | 20x20, 30x30, 40x40 | 6063 |

| Rectangular Tube | 2.0 | Conveyor frames, furniture | 30x20, 40x20, 50x25 | 6061 |

| Angle | 1.2 | Supports, brackets | 20x20, 25x25 | 6063 |

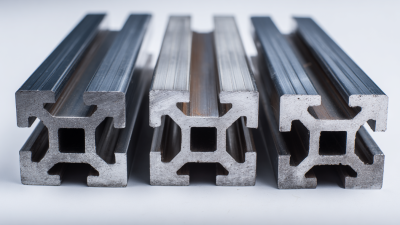

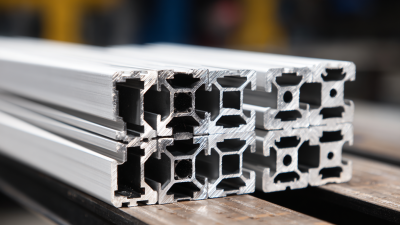

| T-Slot Profile | 1.8 | Modular systems, machines | 20mm, 30mm, 40mm | 6060 |

| Flat Bar | 2.5 | Supports, panels | 25x3, 50x5 | 6061 |

When selecting aluminum profiles for your projects, it's crucial to consider several key factors that can significantly impact both functionality and cost-effectiveness. According to the latest insights from industry reports, the market for aluminum profiles is expected to grow due to increasing demand in construction and manufacturing sectors. Understanding the specific requirements of your project—such as load-bearing capacity, thermal resistance, and corrosion resistance—can help you narrow down your options. The right selection ensures long-term durability and efficiency, aligning with project timelines and budgets.

Moreover, the setup and cost of aluminum anodizing processing plants are also critical considerations. The IMARC Group's report emphasizes that investment in advanced anodizing technologies can enhance the performance of aluminum profiles by improving their surface finish and resistance to environmental factors. For instance, anodized profiles are often preferred for outdoor applications due to their enhanced durability. By integrating these insights into your decision-making process, you can ensure that you choose the most suitable aluminum profiles tailored to your specific project needs.

When embarking on a project that requires aluminum profiles, it’s vital to understand the different types available on the market. Standard aluminum profiles typically come in several categories including structural, decorative, and functional profiles. Structural profiles are designed for strength and stability, making them perfect for building frameworks, while decorative profiles can enhance aesthetic appeal in applications like signage or furniture. Functional profiles often include features like channels or grooves that allow for versatility in design.

Tips: When selecting an aluminum profile, consider the specific requirements of your project such as load-bearing capacity and environmental exposure. Ensure you choose profiles that promote efficient assembly, especially when using modular systems. Additionally, pay attention to the finish of the profiles, as anodized or powder-coated options can significantly enhance durability and maintenance.

Another key aspect to consider is the manufacturing process of the aluminum profile. Extruded profiles offer uniformity and precision, making them a reliable choice for intricate designs. For projects that demand customized shapes, aluminum sheets may also be available for bending or machining. Consequently, assessing your project’s needs against the strengths of various profile types will guide you to make well-informed decisions.

This chart compares the average strength and weight of various standard aluminum profiles commonly used in projects. The profile types assessed include Angular, Rectangular, and Square profiles.

When selecting the best standard aluminum profiles for your projects, evaluating strength, weight, and cost considerations is crucial. Aluminum is known for its excellent strength-to-weight ratio, making it an ideal choice for applications where minimizing weight while maintaining structural integrity is essential. Different aluminum alloys offer varying levels of strength, so it's important to match the alloy to the specific demands of your project. For instance, alloys like 6061 and 6063 are commonly used for their balance of durability and weight, making them suitable for everything from architectural frameworks to automotive parts.

Cost is another significant factor in aluminum selection. The price of aluminum profiles can vary widely depending on the alloy, thickness, and manufacturing processes involved. Standard profiles are often more affordable due to their mass production, so opting for these can help keep project costs down without sacrificing quality. However, it's essential to consider the long-term durability and maintenance costs associated with different profiles, as investing in higher-quality materials may reduce future expenses related to repairs or replacements. Balancing these factors will ensure you choose aluminum profiles that best fit your project requirements while remaining within budget.

When sourcing quality standard aluminum profiles for your projects, it's crucial to understand the market dynamics and identify reliable suppliers. Recent forecasts suggest a significant shift in the global aluminum supply-demand balance, with excess supply expected to narrow by 2026. As the industry gains more attention, suppliers with innovative products and strong quality assurance will be essential.

Tips: Always verify supplier credentials and their production capabilities. Look for companies that emphasize technological innovation and adhere to international standards, as these factors will contribute to the longevity and performance of the aluminum profiles in your applications.

In addition, as aluminum is poised to become a key metal in various sectors, including construction and automotive, consider exploring local manufacturers who are adapting to emerging demands. For instance, the rise of advanced aluminum fabricators highlights the importance of sourcing profiles that not only meet project specifications but also align with sustainability goals. As you approach your project, prioritize partnerships with companies that demonstrate both quality in materials and a commitment to eco-friendly practices.