Choosing the right aluminum extrusion for your project is crucial. Industry expert John Smith once stated, "Selecting the right material can make or break your design." His insight emphasizes the importance of understanding aluminum extrusion.

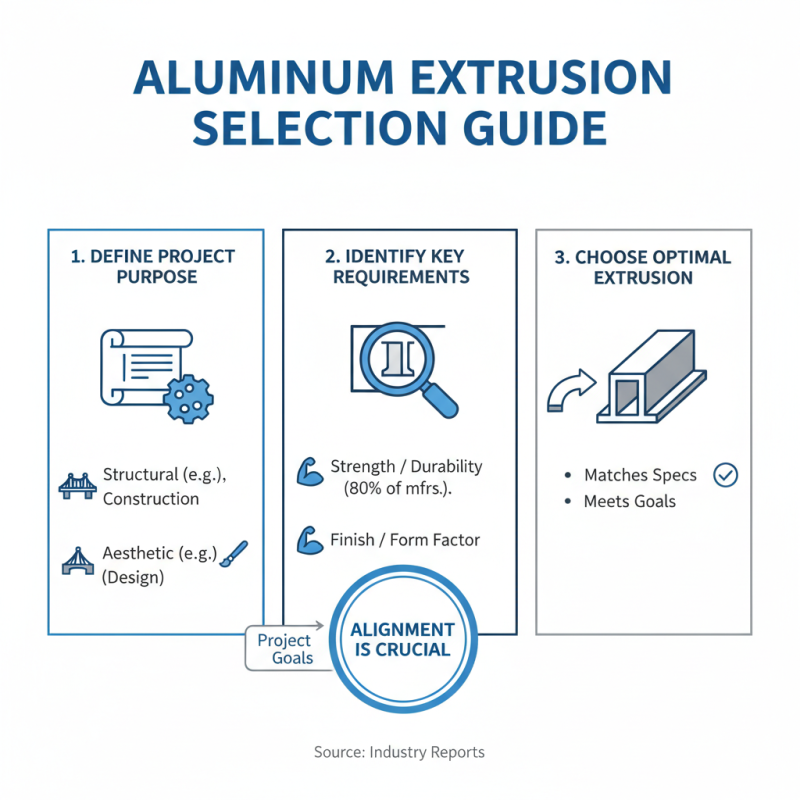

When deciding on aluminum extrusion, consider your project's specifications. Different shapes, sizes, and alloy types can affect the durability and cost. Look closely at the application. Will it be structural? Decorative? The choice of extrusion impacts both functionality and aesthetics.

Sometimes, designers overlook small details. They might select a visually appealing shape without considering weight or strength. Reflecting on past projects is essential. What worked? What didn't? The right decision can lead to success, while the wrong one can cause setbacks. Understanding the nuances of aluminum extrusion is not just smart; it's necessary for achieving your goals.

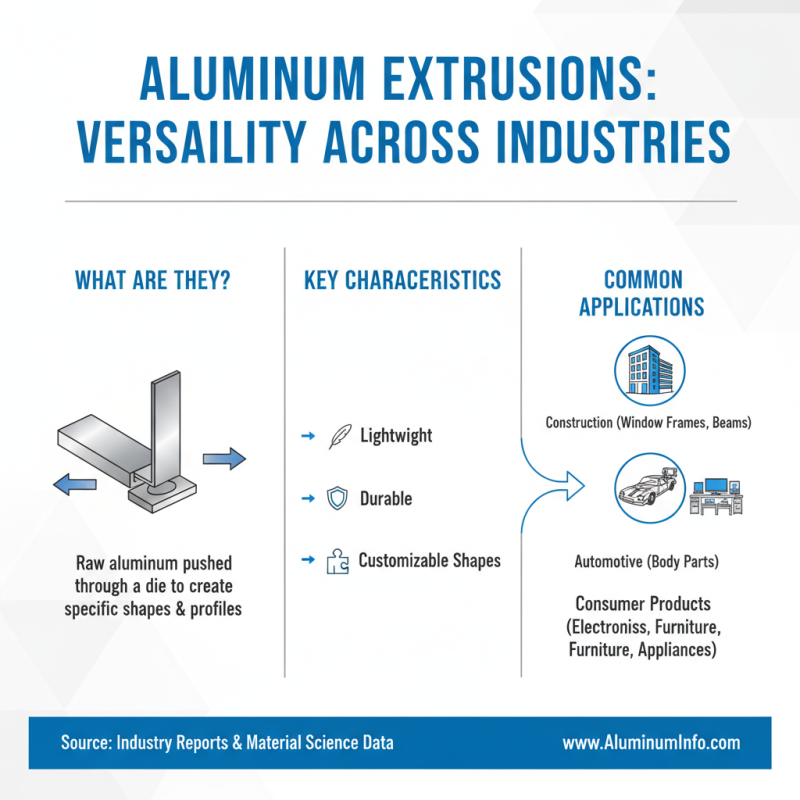

Aluminum extrusions are versatile components used across various industries. They can be found in construction, automotive, and consumer products. These extrusions are created by shaping raw aluminum through an die to produce specific profiles. The result is lightweight yet durable materials suitable for many applications.

Understanding the specific needs of your project is essential. Consider factors like weight, strength, and corrosion resistance. Different alloys offer varying characteristics. An extrusion with a specific cross-section can influence structural integrity.

While selecting extrusions, think deeply about functionality. Poor choices can lead to structural failures or increased costs. It's crucial to visualize how the extrusion fits into your overall design. Testing prototypes can expose potential issues early in the process. Always be ready to adapt your plans based on findings.

When choosing the best aluminum extrusion for your project, understanding your requirements is crucial. Start by considering the purpose of your project. Different applications require distinct specifications. For instance, structural integrity is paramount for construction-related tasks, while aesthetics might be more important for design-focused projects. According to industry reports, approximately 80% of manufacturers highlight the significance of aligning material choices with project goals.

Tips: Clearly define your project's load-bearing requirements. Miscalculating this can lead to future structural failures.

Next, think about the environment in which your aluminum extrusion will be used. Will it face extreme weather conditions? Corrosion-resistant options might be necessary. A study indicates that 70% of aluminum failures are due to improper environmental consideration. This highlights the importance of materials that match your use case effectively.

Tips: Assess your project’s external conditions thoroughly. Use environmental data to guide material selection.

Finally, ensure that you measure the dimensions and tolerances accurately. Precise measurements can prevent costly errors in production. A mistake as small as a few millimeters can derail the entire project timeline. Remember, investing time in this step can lead to better outcomes.

When selecting aluminum extrusion for projects, understanding the different types of aluminum alloys is crucial. Aluminum alloys are generally categorized into two series: 1000 and 6000. Alloys like 6061 are popular for their versatility. They have good corrosion resistance and strength, making them ideal for structural applications. However, they may not be the best choice for high-temperature environments, where alloys like 7075 might be required due to their heat treatment response.

Each aluminum alloy has specific characteristics that affect its performance. For instance, 5052 offers excellent weldability and is often used in marine environments. Yet, it might not provide the same tensile strength as 7075. According to a 2022 report by the Aluminum Association, the demand for 6000 series alloys has surged, accounting for nearly 50% of the market. This indicates a trend towards choosing alloys that balance flexibility with structural integrity.

It’s not just about strength and corrosion resistance; other factors come into play. Consider factors like machining capabilities and color finishing. Some alloys are tougher to machine than others, leading to higher production costs. A study highlighted that 30% of manufacturers reported issues with surface finishes on certain alloys. This can result in higher rework rates, impacting project timelines. Making informed choices will lead to better outcomes.

When selecting aluminum extrusion dimensions and profiles, think about your project's specific requirements. Start by considering the load-bearing needs and weight constraints. The right shape can greatly influence structural integrity. Often, a simple angle or channel can suffice for lightweight applications. Yet, complex sections may be necessary for heavier loads. Don’t overlook how design impacts functionality.

Also, reflect on the profile's aesthetic aspects. The finish can enhance the visual appeal of your project. Some designs may look modern, while others appear more traditional. However, aligning the profile with your vision might require creative compromises. For instance, a sleek design might lack adequate strength. Balancing these elements can be challenging.

Think about other practical factors too. The availability of specific shapes can vary. If a desired profile is hard to find, it could delay your project timeline. Custom extrusions might be necessary, but they come with higher costs. Always weigh the pros and cons of off-the-shelf versus custom options. This choice impacts both budget and delivery times, which can add complexity to your planning.

When considering aluminum extrusions, cost is a crucial factor. The price can vary significantly based on the required specifications and quantity. Short runs of custom profiles can be expensive. On the other hand, purchasing in bulk may offer cost-saving opportunities. Keep in mind that additional processing, like machining or finishing, can also impact the final cost.

Sourcing options for aluminum extrusions are diverse. Local manufacturers might provide faster lead times, but their prices may be higher. Importing extrusions can lower costs, yet shipping and tariffs can add unexpected expenses. Always weigh the benefits of local sourcing against potential delays from overseas suppliers. Engaging with multiple suppliers can also lead to price comparisons, but it requires time and effort.

Sometimes, the cheapest option isn’t the best one. Cutting corners might lead to quality issues down the line. It's beneficial to know the exact requirements of your project before jumping into sourcing. This clarity can help avoid costly mistakes. Reflecting on these aspects will guide you to make informed decisions while balancing cost and quality effectively.

| Project Type | Material Thickness (mm) | Extrusion Length (m) | Price per kg ($) | Supplier Rating | Lead Time (weeks) |

|---|---|---|---|---|---|

| Construction | 3 | 5 | 2.50 | 4.5 | 2 |

| Automotive | 2 | 3 | 3.00 | 4.2 | 3 |

| Electronics | 1 | 1.5 | 4.00 | 4.8 | 1 |

| Aerospace | 4 | 2 | 5.50 | 4.0 | 5 |

| Custom Fabrication | 5 | 6 | 2.80 | 3.9 | 4 |