In the construction and manufacturing industries, choosing the right materials is essential for the success of any project. Aluminum profiles, known for their versatility, strength, and lightweight properties, have become increasingly popular across various applications. According to a recent market report by Allied Market Research, the global aluminum extrusion market is projected to reach $117 billion by 2026, driven by the rising demand for aluminum profiles in automotive, architecture, and consumer goods sectors. With the continuous advancements in aluminum profile technology, understanding their specific properties, such as corrosion resistance, thermal efficiency, and structural integrity, is crucial for making informed decisions. This article aims to guide project managers and engineers through the process of selecting the appropriate aluminum profiles for their next project, ensuring optimal performance and longevity.

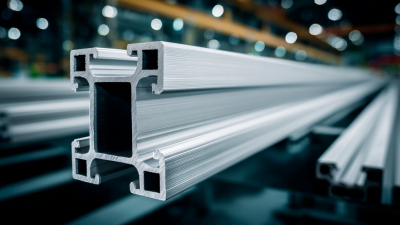

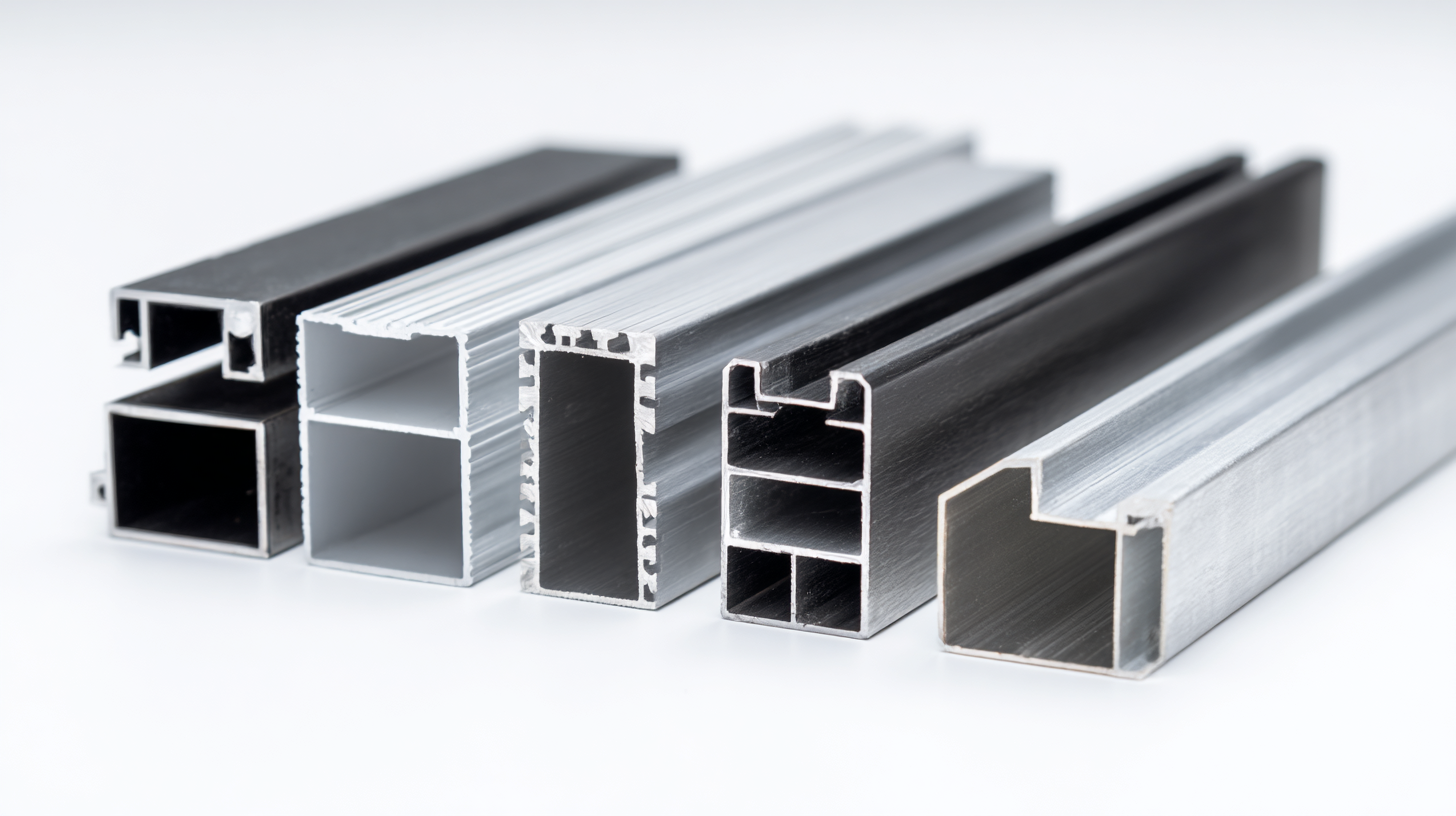

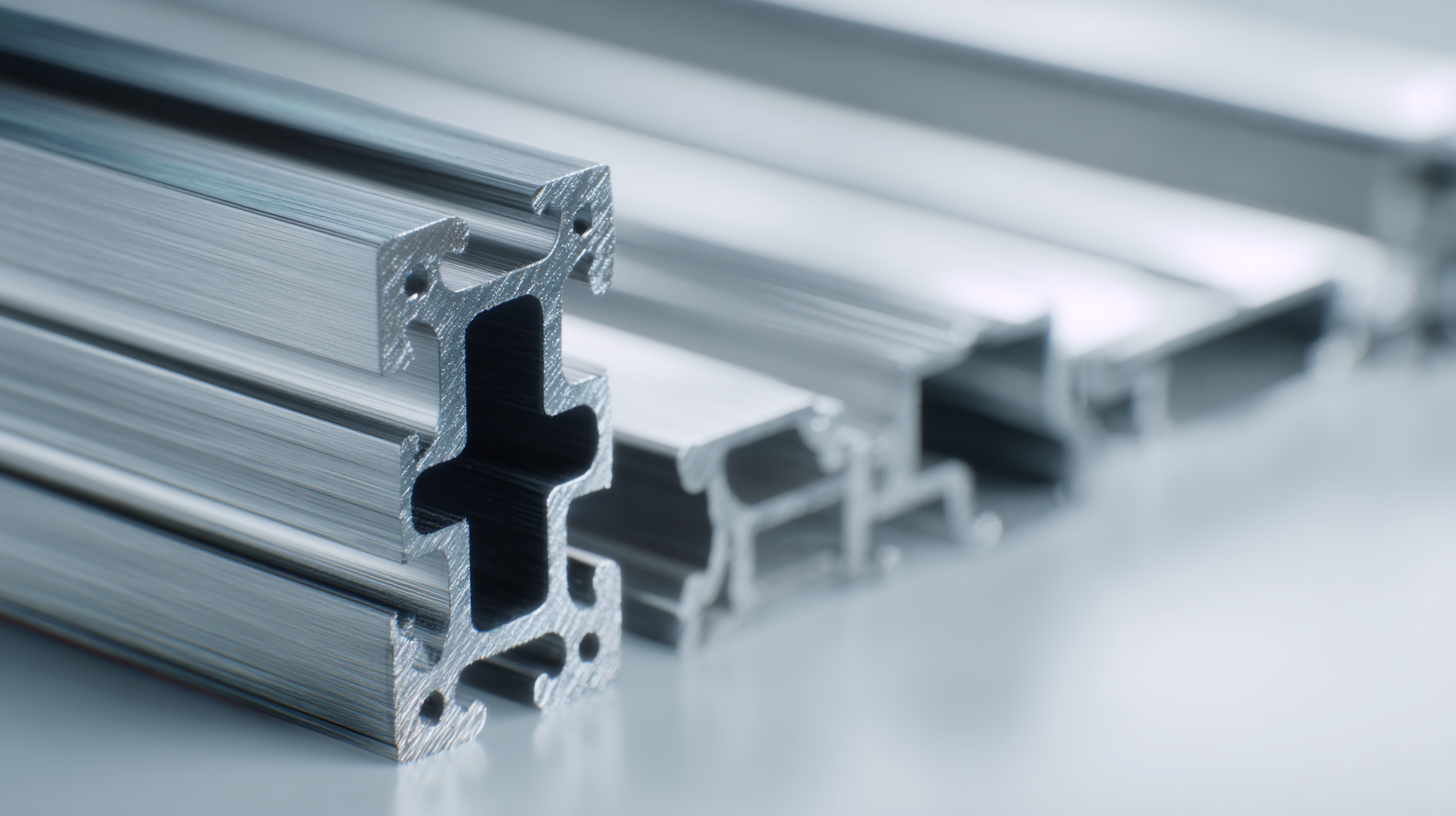

When selecting aluminum profiles for your project, it is essential to understand the various types available on the market. Aluminum profiles can be classified by their manufacturing processes, such as extrusion, which is the most commonly used method. This process involves forcing molten aluminum through a die to create a specific shape, resulting in strong, lightweight profiles ideal for construction and manufacturing applications.

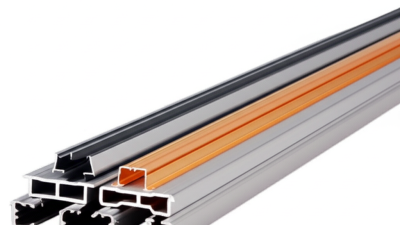

Another category to consider is the specific applications of aluminum profiles, which range from structural components to decorative features. Depending on your project's requirements, you may need profiles that offer specific attributes, such as thermal insulation, corrosion resistance, or aesthetic appeal. Additionally, the choice of the right pigment type for powder coatings can enhance the finish of the profiles, ensuring durability and a pleasing appearance. It’s crucial to assess these factors thoroughly to make an informed decision that aligns with your project goals.

| Profile Type | Common Applications | Dimensions (mm) | Weight (kg/m) | Advantages |

|---|---|---|---|---|

| Square Tube | Frameworks, furniture, and structural parts | 20x20 to 100x100 | 1.0 to 3.0 | Strong, easily welded, versatile |

| Rectangular Tube | Manufacturing, shelving, and racks | 30x20 to 150x80 | 1.5 to 5.0 | High strength, design flexibility |

| Angled Profile | Bracing, corner supports, and frameworks | 20x20 to 90x90 | 0.8 to 3.0 | Rigid, cost-effective |

| Flat Bar | Frames, supports, and decorative elements | 10x3 to 50x10 | 0.5 to 2.0 | Easy to cut and shape, versatile |

| Round Tube | Automotive, fencing, and lighting | 20 to 100 | 0.8 to 3.5 | Aesthetic appeal, lightweight |

When embarking on a new project, the first step in selecting the right aluminum profiles is to thoroughly identify your specific project requirements. Consider the intended application of the profiles—whether they will be used for structural support, aesthetic purposes, or as functional components. Understanding the environment in which these profiles will operate is equally crucial; factors such as exposure to moisture, temperature fluctuations, and potential corrosive elements can influence the type of aluminum alloy you should choose.

Next, assess the physical dimensions and load-bearing capacities needed for your project. This involves evaluating both the weights that the profiles must support and the available space for installation. Additionally, think about the manufacturing processes involved—such as cutting, welding, or machining—that may affect the profile's performance. By clearly defining these requirements, you can streamline the selection process and ensure that your chosen aluminum profiles align with your project's goals, ultimately leading to a more efficient and successful outcome.

When selecting aluminum profiles for your next project, it's essential to evaluate their mechanical properties and strength meticulously. The primary attributes to consider include yield strength, tensile strength, and fatigue resistance. Yield strength determines how much load the material can withstand before it deforms, while tensile strength indicates the maximum load the profile can handle. Fatigue resistance is crucial in applications where the aluminum will undergo cyclic loading. Ensuring these properties align with your project requirements can prevent failures and enhance durability.

Tips: Before making a purchase, consult technical data sheets for each aluminum profile. Look for profiles made from high-grade alloys, as they typically offer superior mechanical properties. Additionally, consider the manufacturing processes used, as techniques like extrusion can affect strength and flexibility.

Another important aspect is to consider the environmental factors that the aluminum profiles will face. Corrosion resistance becomes vital in outdoor or harsh environments, so opting for anodized or treated profiles can offer protection against wear. Taking the time to analyze these factors will ensure a successful project outcome, providing both structural integrity and longevity to your design.

Tips: Use computer simulations or material testing to evaluate how different aluminum profiles respond under expected load conditions. This proactive approach can help you make informed decisions, optimizing both performance and cost-effectiveness.

When selecting aluminum profiles for your next project,

it's essential to consider both aesthetic and functional factors. The design of your profile can

greatly influence the overall appearance of your structure while also contributing to its performance.

Think about how the profile's finish, color, and shape will integrate into your broader design vision.

A well-chosen profile not only enhances visual appeal but also supports the functional requirements

of your project.

Tips: Prioritize profiles with finishes that resist corrosion and wear

for long-term durability, such as anodized or powder-coated options. Additionally, consider

how the shape of the profiles will affect both aesthetics and functionality. For instance,

rounded edges can add a modern touch, while angular designs may offer a more industrial feel.

Another vital consideration is the load-bearing capacity

of the profiles in relation to your design. Ensure that the selected aluminum profiles can support

not just the visual impact but also the structural integrity of your project. Matching the strength

of the aluminum with your project's specific demands will ensure both safety and longevity.

Tips: Consult with manufacturers about the specifications and strength ratings

of different profiles, and don't hesitate to request samples or mock-ups to visualize the final

result in your design context.

When selecting aluminum profiles for your project, calculating cost-effectiveness and availability is crucial. Cost-effectiveness can be assessed by comparing the prices of various aluminum profiles in relation to their intended use. Consider the specific characteristics required for your project, such as strength, weight, and durability. It is also essential to factor in the long-term savings on maintenance and replacement when evaluating the initial price. Cheaper options may seem attractive, but they can lead to higher costs down the line if they do not perform as expected.

Availability is another significant aspect to consider. Ensure that the aluminum profiles you choose are readily available through local suppliers or manufacturers. Delays in procurement can hinder project timelines, so it is wise to research lead times and stock levels. Additionally, consider the supplier’s ability to provide customized solutions, which can sometimes offset higher initial costs by providing a perfect fit for your unique requirements. Balancing these factors will help you select aluminum profiles that are not only affordable but also suitable for your project's long-term success.