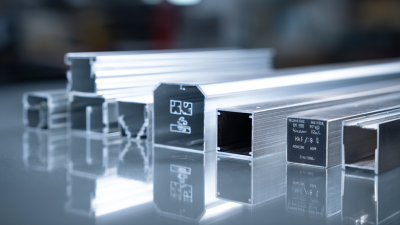

When considering materials for construction projects, many options are available. However, Aluminum Moulding Profiles stand out for several reasons. Their versatility allows for unique and creative designs. They can adapt to various applications, from interior design to exterior architecture.

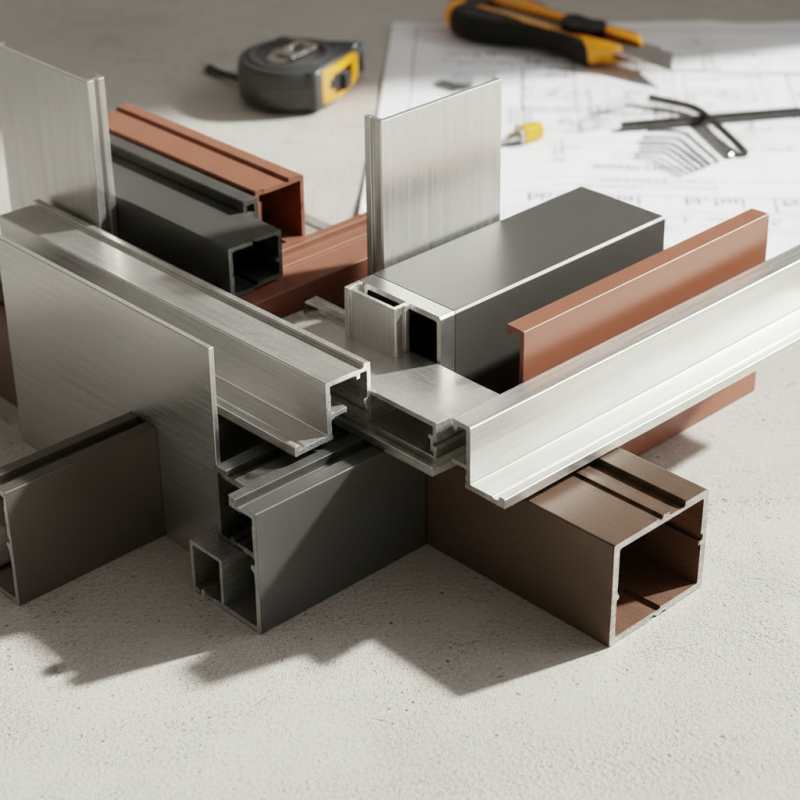

The lightweight nature of aluminum makes it easy to handle. This can reduce overall labor costs and project timelines. Additionally, aluminum profiles are resistant to corrosion, ensuring they maintain their appearance over time. This durability means less frequent replacements, which saves money in the long run.

Despite these advantages, some may think aluminum profiles are too expensive. This perception can deter decisions. It's essential to weigh the upfront costs against long-term benefits. Choosing Aluminum Moulding Profiles can lead to better value in your projects, both aesthetically and functionally.

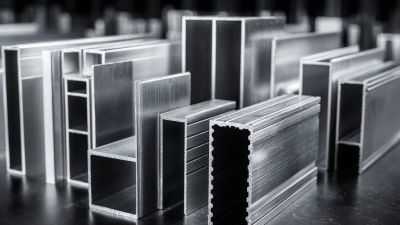

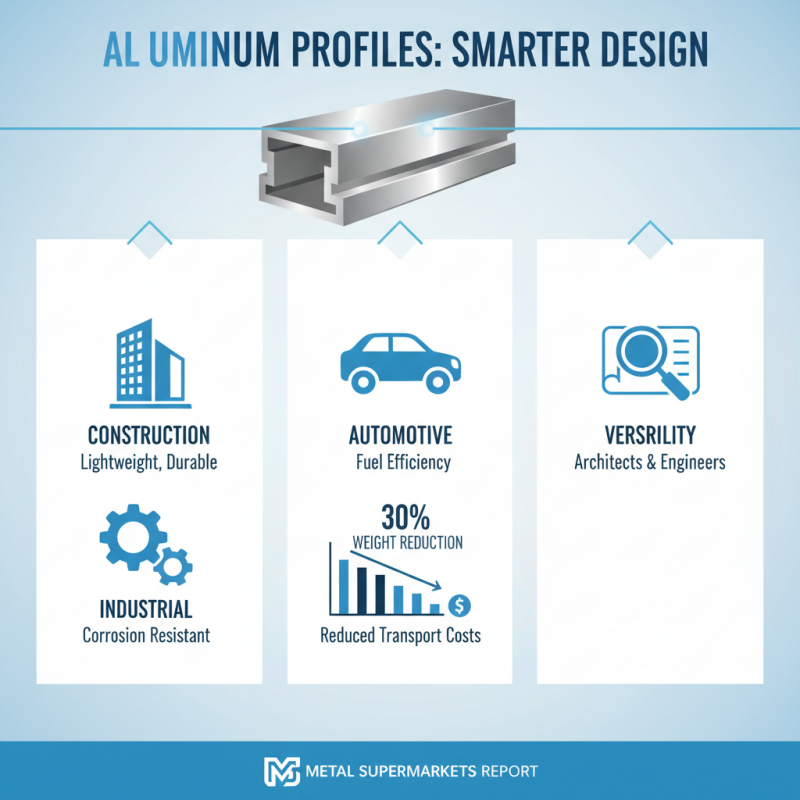

Aluminum moulding profiles offer numerous advantages across various applications. Lightweight yet durable, these profiles are ideal for construction, automotive, and industrial uses. According to a report by the Metal Supermarkets, aluminum's strength-to-weight ratio is advantageous in reducing transport-related costs. Projects can save up to 30% in weight without compromising structural integrity. This makes aluminum an attractive option for architects and engineers alike.

A notable benefit is aluminum's resistance to corrosion. This feature extends the lifespan of structures built with these profiles. The American Institute of Aluminum recommends aluminum for outdoor applications due to its natural resistance to environmental factors. In outdoor settings, aluminum can outlast many alternative materials, making it a cost-effective choice in the long run.

Sustainability is another factor to consider. The International Aluminium Institute states that aluminum is 100% recyclable without losing quality. This characteristic supports eco-friendly initiatives and helps reduce waste. However, the recycling process is not flawless; it requires energy and resources. Project managers must weigh these factors carefully. Making informed decisions can lead to better outcomes in the long term.

Aluminum moulding profiles are increasingly favored for various projects. Their attributes make them a top choice. Durability is a standout feature. Aluminum can withstand harsh conditions without succumbing to rust. Rain, snow, and heat won't easily damage it. Projects exposed to nature need reliable materials.

Resistance is another critical factor. Aluminum does not warp or crack easily. This keeps structures looking good longer. The ability to resist wear and tear means fewer repairs. A project with less maintenance is ideal for time-strapped individuals.

**Tips:** Consider the overall environment where aluminum will be used. Ensure proper thickness for durability. Think about finishes that enhance resistance too. Always weigh your options. Aluminum has benefits, but it could be costlier than other materials. Reflect on your budget versus long-term value.

Cost-effectiveness is a significant factor when choosing materials. Aluminum moulding profiles offer an attractive option for various projects. Their lightweight nature reduces transportation costs. This factor alone can make a notable difference in project budgets. Additionally, aluminum is resistant to corrosion. This durability ensures longer life and less frequent replacements. Over time, this quality can lead to substantial savings.

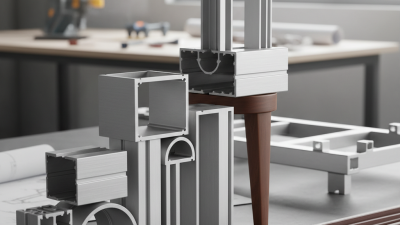

Another aspect to consider is labor costs. Aluminum profiles are often easier to work with. They can be cut and shaped without specialized tools. This flexibility can reduce labor hours during installation. In some cases, this leads to a faster project completion time. However, not all aluminum profiles are created equal. Some might require more skill, costing you extra in training or expertise.

Investing in aluminum profiles can be a double-edged sword. Initial costs might seem high compared to wood or plastic. Yet, they could justify the expense through longevity and reduced maintenance. Despite the numerous benefits, it’s essential to analyze your specific project needs. Understanding your long-term goals can help you make the right choice.

Aluminum stands out as a versatile choice in the design and construction industries. Its lightweight nature allows for innovative structures, reducing the overall load on foundations. Recent studies show that aluminum can reduce energy consumption by up to 30% in various applications due to its insulation properties. This energy efficiency is increasingly vital in today's eco-conscious market.

Architects often leverage aluminum for its adaptability. From sleek facades to intricate moldings, it fits diverse aesthetics. A report from the Aluminum Association indicates that nearly 30% of new buildings are incorporating aluminum in their designs. This trend highlights its appeal in creating modern, sustainable structures. Yet, the challenge remains in balancing design with functionality.

A common concern is the maintenance of aluminum products. While they resist corrosion better than other metals, proper finishing is still essential. Projects can face setbacks if not monitored closely. The impact of these oversights reflects in costs and timelines. Designers must continuously refine their approaches to fully embrace aluminum’s potential while addressing its complexities.

Aluminum moulding profiles are increasingly favored for their environmental advantages. According to a study by the Aluminum Association, aluminum can be recycled indefinitely, with over 75% of the aluminum ever produced still in use today. This means less energy is required for new products, mitigating environmental impact. The recycling process uses only 5% of the energy needed for primary aluminum production. This significant reduction can help curb greenhouse gas emissions.

Moreover, aluminum is lightweight, which contributes to lower fuel consumption in transportation. A report from the International Aluminum Institute states that lighter materials can improve vehicle efficiency by up to 30%. However, the environmental footprint of aluminum production remains a concern due to mining and smelting processes. These steps can release harmful pollutants if not managed properly. Such realities call for better practices in sourcing and processing aluminum materials.

Notably, the life cycle analysis of aluminum shows a mixed picture. While aluminum profiles enhance sustainability through reuse, the initial industrial input can be challenging to assess. The key is balancing immediate environmental costs with long-term benefits. Awareness of these trade-offs can influence project decisions significantly. Choosing aluminum must involve a nuanced understanding of the entire lifecycle, not just the end product.

| Dimension | Description | Environmental Benefits | Recycling Potential |

|---|---|---|---|

| Weight | Lightweight compared to other materials | Low energy consumption during transportation | 100% recyclable without loss of quality |

| Durability | Corrosion-resistant and long-lasting | Reduced need for replacements, lowering waste | Easily processed for recycling |

| Manufacturing Impact | Less energy-intensive production compared to steel | Lower greenhouse gas emissions during manufacturing | Strong market demand for recycled aluminum |

| Versatility | Adaptable for various design and engineering needs | Facilitates innovative and sustainable designs | Used in different products promoting recycling |