In today's manufacturing landscape, the advantages of Aluminum Extrusion Profiles are increasingly recognized. Experts like Dr. Jane Thompson, a leading figure in material science, emphasize their potential. She once stated, “Aluminum extrusion opens doors to innovation in various projects.” This sentiment captures the essence of why these profiles are favored.

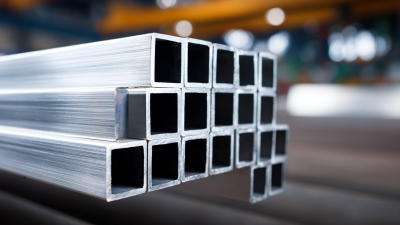

Aluminum Extrusion Profiles offer durability, versatility, and efficiency. They can be tailored to meet specific project needs. For instance, in construction, they provide lightweight solutions without compromising strength. However, choosing the right extrusion can be challenging. It requires careful thought about design and application.

Cost can be a crucial factor as well. While initial expenses may be higher, the long-term benefits often outweigh these costs. Yet, many projects overlook the importance of selecting quality extrusion profiles. Understanding the balance between cost and functionality is vital for success. Careful evaluation can lead to better decisions.

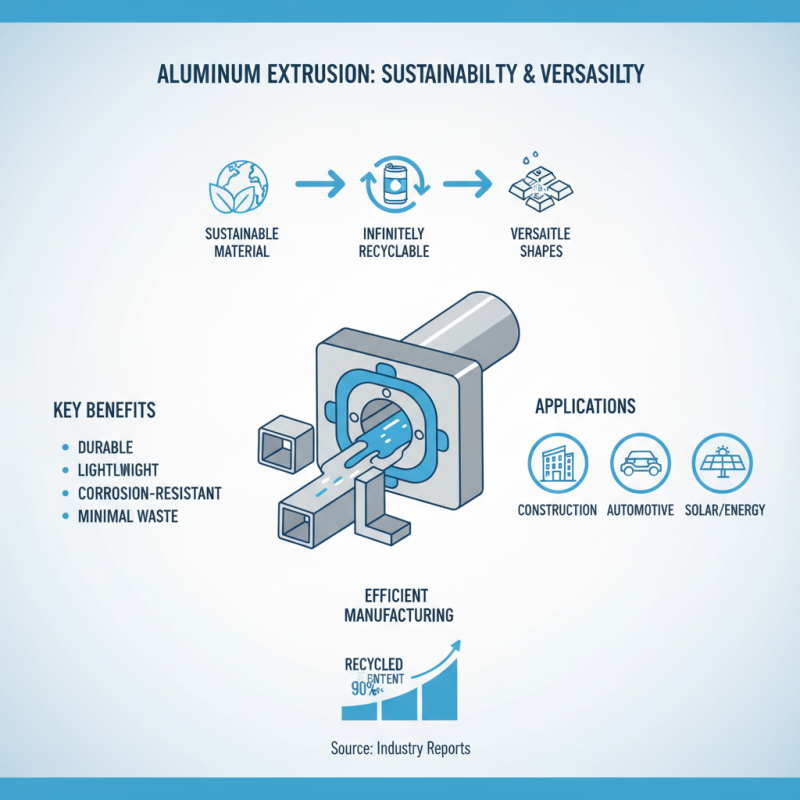

Aluminum extrusion profiles offer numerous advantages across various industries. Their lightweight nature is crucial for transportation and manufacturing sectors. This property reduces energy consumption during transport. Projects become more efficient as a result. Additionally, aluminum resists corrosion. It withstands harsh environments, making it ideal for outdoor applications.

The versatility of aluminum extrusion profiles is striking. They can be used in construction, automotive, and even electronics. This adaptability allows for customized designs tailored to specific needs. In construction, for example, aluminum frames provide durability without adding excessive weight. Designers appreciate how easy it is to shape and mold aluminum into different forms.

However, it's essential to recognize the limitations. Improper handling can lead to dents. Some manufacturers may not achieve the desired precision. This can affect the overall quality of projects. Evaluating the production process is crucial. A focus on quality control can significantly improve outcomes. Embracing aluminum extrusion profiles often means balancing benefits with possible challenges.

Aluminum extrusion profiles are gaining popularity in various applications. Their unique properties make them a superior choice for many projects. One of the standout features is their lightweight nature. According to the Aluminum Association, aluminum is about one-third the weight of steel, yet it maintains excellent strength. This combination allows for easier handling and reduced transportation costs.

Moreover, aluminum extrusions are highly resistant to corrosion. A study from the International Aluminum Institute shows that aluminum can withstand harsh environmental conditions. This durability is essential for projects exposed to moisture and other corrosive elements. For example, in construction, aluminum frames are used in windows and facades due to their longevity and low maintenance requirements.

Thermal conductivity is another key aspect. Aluminum conducts heat well, making it suitable for applications where heat dissipation is critical. This property is vital in the automotive and electronics industries. However, thermal expansion can be a concern. Designers need to account for this to avoid structural issues. It's a point that requires careful planning in projects. Using aluminum extrusions enhances durability but also demands awareness of these intricacies.

| Property | Description | Benefits |

|---|---|---|

| Lightweight | Aluminum is significantly lighter than other metals, making it easy to handle and transport. | Reduces shipping and assembly costs; easier installation. |

| Corrosion Resistance | Aluminum naturally generates a protective oxide coating, preventing rust and deterioration. | Increases lifespan and reduces maintenance costs. |

| Strength-to-Weight Ratio | Aluminum offers high strength without the heaviness of steel. | Allows for thinner designs while maintaining structural integrity. |

| Recyclability | Aluminum is 100% recyclable without loss of quality. | Contributes to sustainable practices and reduces waste. |

| Thermal Conductivity | Aluminum efficiently transfers heat and cold. | Ideal for applications requiring excellent thermal management. |

Aluminum extrusions offer significant advantages over other materials in construction. They are lightweight yet strong, making them easy to handle. Unlike steel, aluminum does not corrode, ensuring longevity in various environments. Wood, while aesthetically pleasing, faces issues with pests and requires more maintenance.

Choosing aluminum also offers design flexibility. It can be shaped into complex forms that wood or steel cannot achieve easily. Additionally, aluminum is recyclable, reducing environmental impact. This aspect appeals to eco-conscious builders and homeowners.

Tips: Consider your project's specific needs. Evaluate weight, strength, and finish. Don't overlook the cost-effectiveness of aluminum. Sometimes, its initial price may be higher, but savings on maintenance and durability can be worthwhile.

Selecting the right materials requires thought. Not every project needs aluminum. For simple structures, wood might suffice. Reflect on your goals and choose wisely. Combining materials can sometimes yield the best results.

Aluminum extrusions have become a staple in modern design and engineering. They are versatile and lightweight, making them suitable for a broad range of applications. From window frames to structural components, aluminum profiles offer excellent strength without the bulk. Architects and designers appreciate the flexibility of aluminum in creating unique shapes and designs.

These profiles are widely used in the automotive industry. They contribute to the production of lightweight vehicles, improving fuel efficiency. In the field of renewable energy, aluminum extrusions help produce frames for solar panels. This application emphasizes durability and resistance to environmental factors. However, challenges remain in ensuring proper joints and connections within these applications, requiring careful planning and execution.

The use of aluminum extrusions in furniture design is also noteworthy. They can create sleek, modern aesthetics, perfect for contemporary spaces. Yet, achieving the desired finish can be tricky. Sometimes, surface imperfections are noticeable, leading to a need for reevaluation of manufacturing processes. Designers must strike a balance between aesthetics and functionality to create enduring pieces.

Aluminum stands out for its sustainability and recycling potential. As a widely used material, it can be molded into various shapes through extrusion. This process minimizes waste and maximizes efficiency. Aluminum profiles are durable, lightweight, and resistant to corrosion. These qualities make them ideal for a range of applications, from construction to automotive.

When it comes to recycling, aluminum shines brightly. It is 100% recyclable without losing its quality. This means that products made from recycled aluminum can be used repeatedly. In fact, recycling aluminum saves up to 95% of the energy needed to produce new aluminum. This is a compelling reason for industries to choose aluminum.

Tips: Consider local recycling options when using aluminum. This reduces transport emissions. Also, choose aluminum products that are made from post-consumer recycled materials. Reflect on how your choices impact the environment. Small changes can lead to significant benefits over time. Aim to design projects that prioritize sustainability. It not only helps the planet but also appeals to eco-conscious consumers.