In today's competitive construction and manufacturing landscape, the selection of the right Aluminum Profiles is crucial for optimizing performance and cost-effectiveness in various projects. According to a recent industry report by Global Market Insights, the aluminum profile market is projected to reach over USD 160 billion by 2026, driven by increasing demand in sectors such as automotive, aerospace, and building and construction. The versatility of aluminum profiles, coupled with their lightweight nature and corrosion resistance, makes them an ideal choice for a wide array of applications. As fabricators and builders navigate this booming market, having a comprehensive checklist for selecting the right aluminum profiles becomes essential to ensure that they meet both performance specifications and regulatory requirements. With this in mind, end-users must evaluate factors such as alloy type, anodizing options, and fabrication techniques, thus enhancing project outcomes and durability.

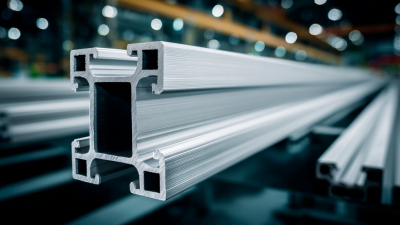

When selecting aluminum profiles for your projects, it's crucial to have a deep understanding of their various types and applications. Aluminum profiles come in different shapes, each designed for specific purposes. For example, extruded profiles are favored in construction and manufacturing for their strength and versatility. Structural channels and angles provide support for frameworks, while tubes are ideal for applications requiring fluid flow or lightweight structures. According to industry reports, the demand for aluminum profiles is expected to grow significantly, driven by advancements in manufacturing techniques and the increasing use of lightweight materials.

**Tips:** Always assess the specific requirements of your project—consider weight, load-bearing capacity, and environmental factors. For instance, anodized aluminum profiles can enhance corrosion resistance, making them ideal for outdoor applications.

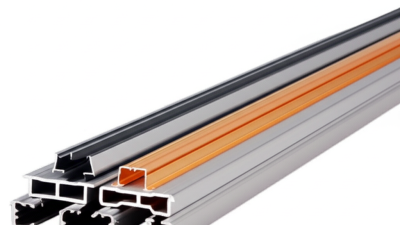

In addition to understanding the types of profiles, it's essential to consider customization options. Many suppliers offer tailored solutions to meet unique project specifications, ensuring optimal performance and efficiency. Data from recent market analyses show that tailored aluminum profiles can significantly reduce waste during production, which is increasingly important for sustainable building practices.

**Tips:** Collaborate with a trusted supplier who can provide insights into the latest innovations and materials, helping you select the most suitable aluminum profiles tailored to your needs.

When selecting aluminum profiles for your projects, understanding the key factors can significantly impact the success of your design. One of the most important considerations is the application of the profiles. Different applications require different strength, flexibility, and weight characteristics. For instance, if you are working on a project that involves heavy loads, opt for high-strength aluminum alloys that can withstand significant stress without bending or deforming.

Another critical factor to evaluate is the environmental conditions the profiles will face. Aluminum is naturally resistant to corrosion, but certain environments may require additional coatings or treatments to enhance durability. For instance, profiles exposed to saltwater or harsh chemicals should have a protective coating to prevent long-term damage.

Tips: When choosing aluminum profiles, always check the manufacturer's specifications for load-bearing capacities and ensure they align with your project's requirements. Moreover, consider the finish of the aluminum. Anodized, powder-coated, or mill-finished profiles can affect not only the aesthetics of your project but also its resistance to environmental factors. Finally, consult with suppliers about custom solutions if your design involves unique dimensions or performance characteristics that standard profiles cannot meet.

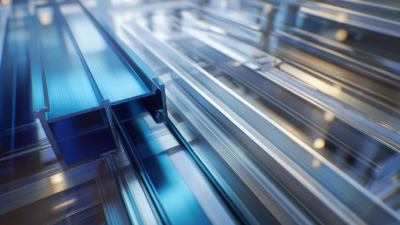

Aluminum profiles have become a go-to choice for construction projects, largely due to their durability and performance advantages. One of the standout features of aluminum is its natural resistance to corrosion, which ensures that structures maintain their integrity over time. Unlike other materials, aluminum doesn’t rust, making it ideal for buildings in various environments, from coastal areas with high humidity to regions prone to heavy rainfall. This characteristic not only extends the lifespan of the construction but also reduces maintenance costs, allowing projects to stay within budget and timeline.

In addition to their longevity, aluminum profiles contribute significantly to the overall performance of structures. Their lightweight nature allows for easier handling and installation, which can accelerate project completion. Moreover, aluminum is highly adaptable; it can be extruded into a variety of shapes and sizes to meet specific design requirements, enhancing the architecture of a building while maintaining strength and stability. Furthermore, aluminum profiles can be engineered to meet strict energy-efficiency standards, contributing to sustainable building practices. The combination of durability, ease of use, and design versatility makes aluminum profiles an invaluable asset in modern construction projects.

When choosing materials for construction and manufacturing projects, the cost-effectiveness of aluminum profiles becomes a significant factor. According to a report by the Aluminum Association, aluminum can be up to 30% lighter than steel and 17% lighter than other common materials like PVC. This reduction in weight not only lowers transportation costs but also reduces the structural load, leading to savings in other materials and construction expenses. With aluminum’s durability and corrosion resistance, the long-term maintenance costs are also lower compared to other materials.

Tip: Always compare the lifecycle costs of materials. While aluminum may have a higher initial purchase price, its longevity and durability can result in overall savings over time.

Moreover, the recycling aspect of aluminum enhances its cost-effectiveness. The International Aluminum Institute states that 75% of all aluminum ever produced is still in use today due to its recyclability. This sustainable feature adds value to aluminum profiles, as recycled aluminum requires only 5% of the energy used to create new aluminum.

Tip: When selecting materials, consider not only the initial costs but also the potential environmental impact and future resale value of the materials used in your projects.

When considering materials for construction and design projects, sustainability plays a crucial role in the decision-making process. One of the top choices for environmentally conscious professionals is aluminum profiles. They are not only lightweight and durable but also offer significant sustainability benefits that can greatly enhance any project’s eco-friendliness. Aluminum is highly recyclable, with the potential for up to 75% of its material being reused multiple times without degradation in quality. This cyclical nature of aluminum consumption minimizes waste and conserves natural resources, making it a standout option for sustainable building practices.

Moreover, the production of aluminum profiles has evolved significantly, with advancements aimed at reducing energy consumption and emissions. Many manufacturers now use renewable energy sources in their processes, further decreasing the carbon footprint associated with aluminum production. Additionally, aluminum's long lifespan contributes to sustainability by reducing the need for frequent replacements, leading to lower overall resource usage over time. By selecting aluminum profiles for your projects, you not only contribute to a greener planet but also gain access to a versatile material that can meet a wide range of design and structural requirements.

| Criteria | Description | Benefits |

|---|---|---|

| Material Strength | Aluminum profiles offer high strength-to-weight ratios. | Durable structure with reduced material usage. |

| Recyclability | Aluminum is 100% recyclable without loss of quality. | Promotes circular economy and reduces waste. |

| Thermal Conductivity | Excellent thermal conductor, ideal for energy-efficient designs. | Lower energy costs and improved comfort in buildings. |

| Corrosion Resistance | Aluminum naturally forms a protective oxide layer. | Extended lifespan and reduced maintenance costs. |

| Lightweight | Aluminum is significantly lighter than other metals. | Easier handling and lower transportation costs. |