The use of aluminium extruded for sunroom projects has gained significant traction in recent years, aligning with the growing consumer demand for energy-efficient and aesthetically appealing outdoor spaces. According to a 2022 report from the Aluminium Association, the global aluminium extrusion market is projected to reach $80 billion by 2025, with a notable increase attributed to housing and home improvement sectors. This trend highlights the material's advantages, including its lightweight nature, durability, and resistance to corrosion, making it an ideal choice for sunroom structures.

However, navigating the challenges associated with aluminium extrusions—such as material sourcing, design complexities, and manufacturing processes—can prove daunting for homeowners and contractors alike. Understanding these obstacles is crucial to ensure a successful sunroom project that not only meets design aspirations but also adheres to industry standards.

Understanding aluminium extrusions is crucial for anyone considering a sunroom construction project. These extrusions are pre-shaped pieces of aluminium that provide strength and versatility, making them ideal for creating robust, long-lasting frames. Their unique properties allow for innovative designs and seamless integration with glass panels, ensuring that your sunroom not only looks great but also performs optimally in various weather conditions.

When selecting aluminium extrusions for your sunroom, it's important to consider factors such as durability, thermal performance, and maintenance. High-quality extrusions prevent warping and corrosion, which are essential for the longevity of your sunroom. Additionally, advancements in thermal break technology can enhance insulation, keeping your space comfortable year-round. By understanding these elements, you can make informed decisions that contribute to the overall success of your sunroom project.

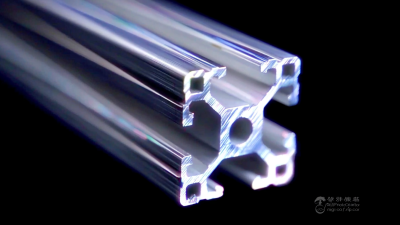

When embarking on a sunroom project, understanding the common challenges associated with aluminum extrusions is crucial for ensuring a successful outcome. One major issue is the quality control of the extruded materials. Poorly manufactured aluminum can lead to brittle frames or inconsistent finishes, which not only jeopardizes the structural integrity but also affects the overall aesthetics of the sunroom. Scrutinizing the supplier’s production standards and seeking materials that adhere to industry benchmarks can mitigate this risk significantly.

Another challenge stems from the complexities of design and fabrication. Aluminum extrusions must be accurately designed to fit the specific dimensions and features of the sunroom. Inadequate attention to detail during the design phase can result in costly modifications or reworks down the line. Additionally, the joining of extruded pieces requires specialized equipment and techniques to ensure they are both functional and visually appealing. Collaborating closely with experienced fabricators and consulting with design professionals can help navigate these intricacies, leading to a smoother construction process and a superior final product.

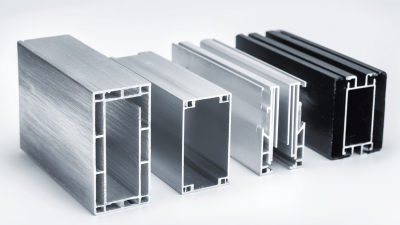

When embarking on a sunroom project, selecting the right aluminium profiles is crucial for ensuring both aesthetics and structural integrity. Begin by understanding the specific requirements of your sunroom. Consider factors such as the intended design, exposure to weather, and local building codes. Each aluminium profile varies in strength, durability, and insulation properties, so it's essential to choose profiles that can withstand outdoor elements while providing optimal thermal performance.

Next, evaluate the finishes and colors available for your chosen aluminium profiles. A well-chosen finish not only enhances the visual appeal of your sunroom but also acts as a protective layer against corrosion and fading. Options like powder coating or anodized finishes can provide longevity and require less maintenance over time. Lastly, consulting with manufacturers or professionals who specialize in aluminium extrusions can give you insights into the best practices and help you navigate the complexities of your selection process. By doing thorough research and focusing on these key elements, you'll ensure that your sunroom is both beautiful and functional.

When working on your sunroom project, proper handling and installation of aluminium extrusions is crucial to ensure durability and aesthetic appeal. First and foremost, always handle the extrusions with care. Use gloves to prevent oils from your fingers from leaving marks on the surface. Additionally, transport the materials securely to avoid any bending or dents, which could compromise their structural integrity. If possible, keep the extrusions in their protective packaging until you're ready to install them, as this helps shield them from scratches and environmental elements.

During installation, precision is key. Begin by measuring and marking your layout thoroughly to ensure that each extrusion fits perfectly within the planned dimensions. Use appropriate tools, such as a level and a square, to maintain straight lines and accurate angles throughout the process. Additionally, consider pre-drilling holes to prevent the aluminium from cracking and ensure a smoother assembly. Remember to allow for thermal expansion, especially in outdoor environments, which can affect the alignment of your sunroom's structure over time. By following these tips, you'll set the foundation for a successful and lasting sunroom installation.

This chart illustrates the common challenges faced during the installation of aluminium extrusions in sunroom projects, along with the percentage of respondents who encountered these issues. Proper handling and installation are crucial for ensuring the longevity and stability of your sunroom.

Maintaining aluminium extrusions is essential for ensuring the longevity and performance of your sunroom. These extrusions, while durable, can be susceptible to the effects of weather and other environmental factors. Regular cleaning is the first step in maintenance; a gentle wash with soap and water can remove dirt, debris, and contaminants. For more stubborn stains or buildup, a soft scrub with a non-abrasive cleaner is recommended. This practice not only keeps the surfaces looking pristine but also prevents corrosion that could compromise structural integrity.

In addition to cleaning, it is crucial to inspect the seals and joints of your aluminium extrusions periodically. Over time, weatherstripping and sealants can wear down, leading to leaks and drafts. Replacing these components as needed will enhance energy efficiency and comfort in your sunroom. Furthermore, applying a protective coating or finish can greatly extend the lifespan of the aluminium, safeguarding it against UV rays and moisture. By prioritizing these maintenance practices, you can ensure that your sunroom remains a beautiful and functional space for years to come.