In the ever-evolving landscape of construction and manufacturing, the demand for Standard Aluminum Profiles has surged, driven by their versatility, durability, and lightweight nature. According to a recent market research report by Grand View Research, the global aluminum profiles market is projected to reach USD 70 billion by 2028, highlighting a robust growth rate as industries shift towards more sustainable materials. This growth is attributed to the increasing adoption of aluminum profiles in various applications, from architectural designs to automotive components.

Selecting the right Standard Aluminum Profiles for your next project is crucial, as it not only impacts structural integrity but also affects aesthetic appeal and cost-efficiency. Understanding best practices in selection can lead to significant benefits, ensuring the optimal performance and sustainability of your projects in a competitive marketplace.

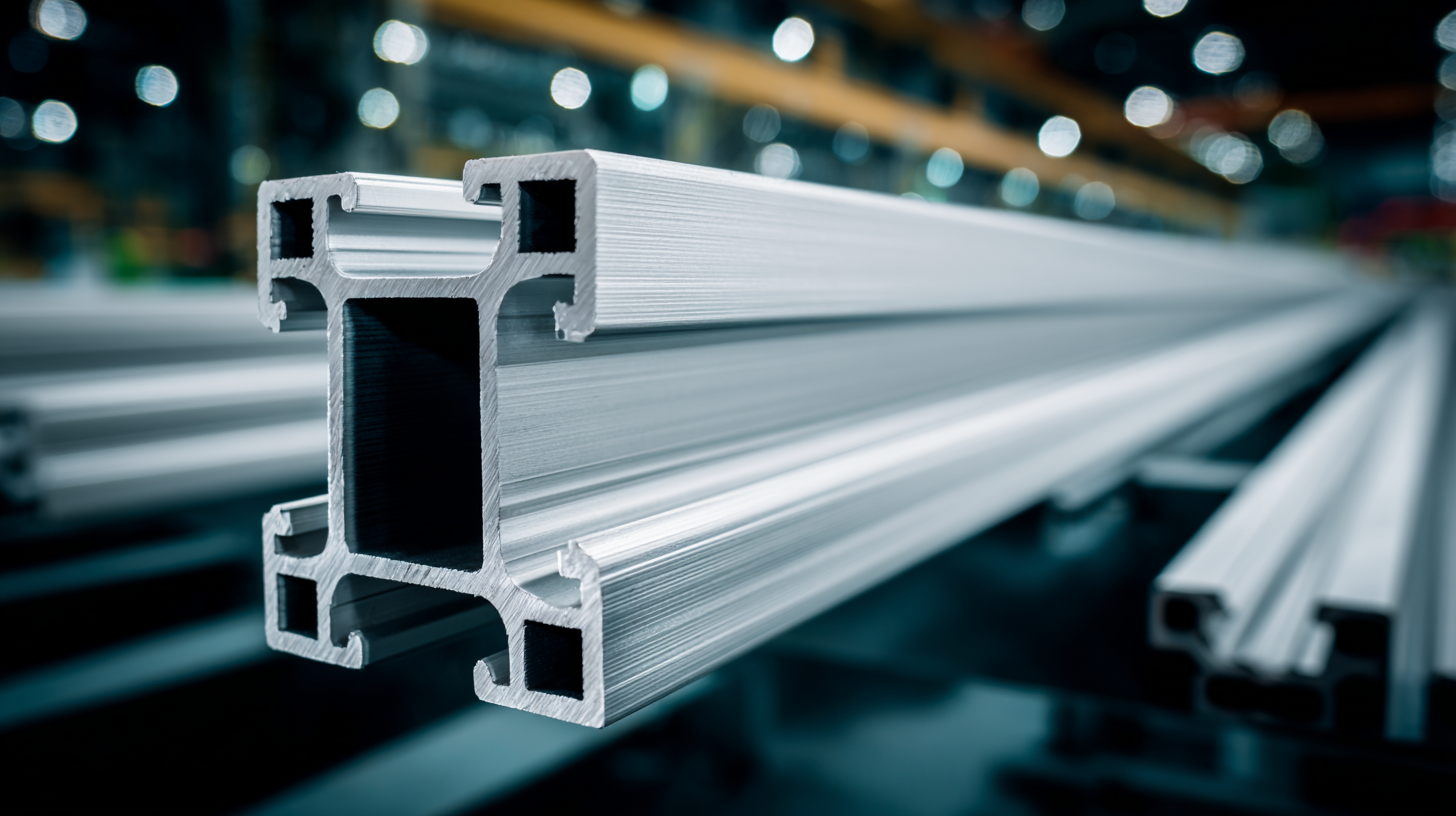

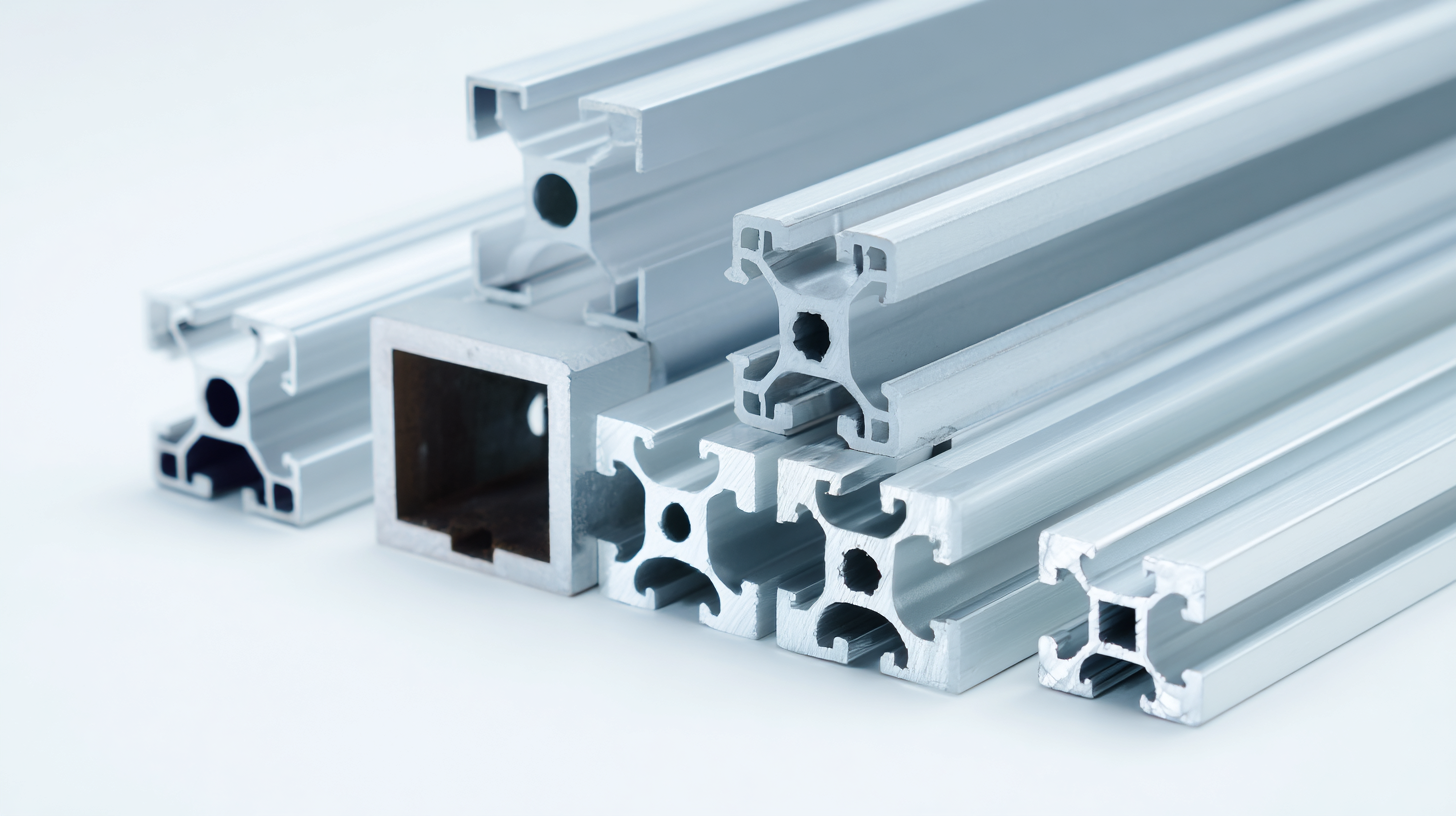

Standard aluminum profiles play a crucial role in construction projects due to their versatility, durability, and aesthetic appeal. These profiles are widely used in various applications, from structural frameworks to decorative elements. Their lightweight nature combined with high strength makes them an ideal choice for modern architecture and industrial designs. By utilizing standard aluminum profiles, architects and builders can streamline the construction process, reducing both time and labor costs while ensuring a robust outcome.

Understanding the importance of standard aluminum profiles also entails recognizing their contribution to sustainability in construction. Aluminum is a highly recyclable material, which aligns with the growing emphasis on eco-friendly building practices. The availability of standardized profiles ensures consistency and quality, making it easier for construction teams to meet project specifications while minimizing waste. By selecting the right aluminum profiles, stakeholders can not only enhance the functionality and appearance of a structure but also adhere to environmental standards, benefiting the overall project and its impact on the community.

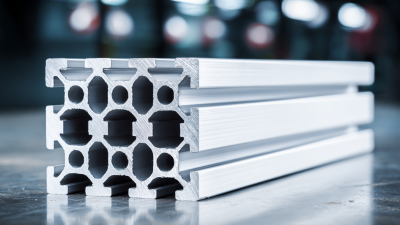

When selecting standard aluminum profiles for your next project, several key factors are crucial to ensure optimal performance and durability. Firstly, the intended application plays a significant role. Whether for structural support, aesthetic design, or thermal management, it is essential to choose a profile that meets specific load-bearing and functional requirements. According to industry reports, utilizing the appropriate aluminum grade can enhance strength by up to 30%, significantly affecting the longevity and reliability of the finished product.

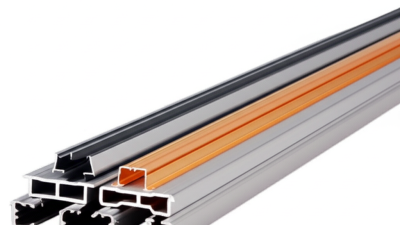

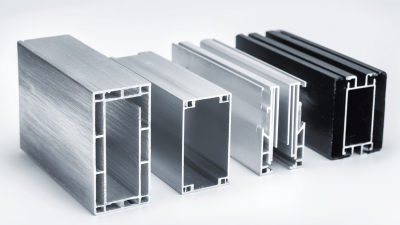

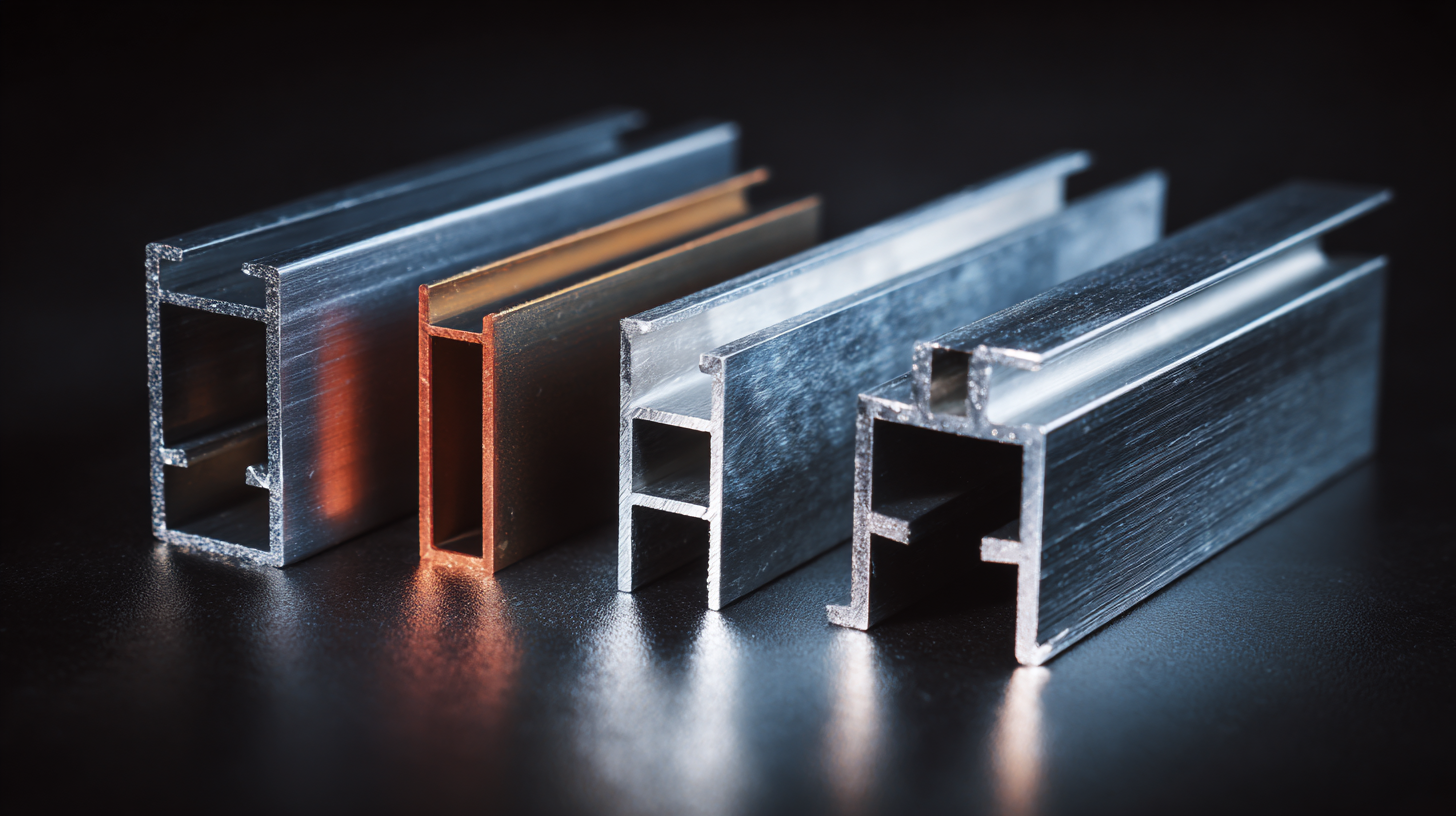

Another critical consideration is the surface treatment of the aluminum profiles. Finishing processes like anodizing not only improve the aesthetic appeal but also contribute to corrosion resistance and surface hardness. Data indicates that treated aluminum surfaces can withstand environmental stressors effectively, extending their lifespan in various applications. Moreover, ensuring compatibility with other materials and ease of assembly is vital for project efficiency. Selecting profiles that integrate well with existing systems can reduce operational costs by up to 15%, making the selection process an essential step for project success.

| Criteria | Description | Considerations |

|---|---|---|

| Material Quality | Ensure the aluminum profile is made of high-quality aluminum alloy. | Look for certified materials and check for standards compliance. |

| Profile Design | Choose profiles that match the design specifications of your project. | Consider factors like load-bearing capacity and aesthetic appeal. |

| Dimensional Compatibility | Ensure profiles meet the specific dimensional requirements of your application. | Verify tolerances and dimensions through technical drawings. |

| Surface Treatment | Select the appropriate surface treatment for durability and aesthetics. | Consider options like anodizing, powder coating, or wood finish. |

| Weight and Load Requirements | Analyze the weight and load requirements before selection. | Ensure the profile can handle the operational loads expected. |

| Availability and Lead Time | Check the availability of the profiles and their lead times. | Consider stock levels and delivery schedules for project timelines. |

| Cost Efficiency | Evaluate cost-effectiveness regarding budget constraints. | Compare alternatives and assess long-term value versus upfront cost. |

Selecting the right aluminum profile can dramatically influence the efficiency of your project. According to a recent industry report by the Aluminum Association, the choice of aluminum structures can improve overall project timelines by up to 30%. This efficiency not only stems from the light weight and high strength of aluminum but also from optimized design flexibility, allowing for easier modifications during the construction phase. The ability to quickly adapt to design changes minimizes downtime, ultimately leading to significant cost savings.

To maximize the benefits of aluminum profiles, consider the following tips:

By focusing on these best practices, project managers can ensure that their selection of aluminum profiles not only meets structural requirements but also aligns with the overarching goals of efficiency and cost-effectiveness.

When selecting aluminum profiles for your project, understanding the balance between cost and performance is crucial. According to a recent study by the Aluminum Association, the total lifecycle cost of an aluminum profile can be up to 30% lower than that of competing materials when considering durability, maintenance, and recyclability. This emphasizes that while the upfront cost may be attractive, examining long-term performance can yield significant savings.

Tip: Always request performance data from suppliers, including load-bearing capacity and corrosion resistance, to ensure that the profiles will meet your project requirements.

In a comparative analysis, a report from the International Aluminum Institute highlights that high-performance aluminum alloys can improve structural integrity without significantly increasing costs. For instance, investing in a higher-grade aluminum profile could provide 15-20% more strength per weight, enabling more streamlined designs and reducing the overall material requirement.

Tip: Evaluate different alloys for specific applications, as selecting the right profile can enhance both the performance and cost-effectiveness of your project, ensuring longevity and efficiency.

When selecting standard aluminum profiles for your next project, considering sustainability is not just a trend; it's an essential practice for eco-conscious development. According to a report by the International Aluminium Institute, aluminum is 100% recyclable without any loss in quality, making it a highly sustainable material choice. By opting for recycled aluminum profiles, companies can reduce energy consumption by up to 95% compared to producing new aluminum from raw materials. This significant reduction not only lowers carbon emissions but also conserves natural resources, enhancing the overall environmental impact of your project.

Tips for eco-friendly profile selection include assessing material sourcing. Look for suppliers who commit to sustainable practices and offer products with a high percentage of recycled content. Additionally, consider the life cycle of aluminum profiles; choosing durable and long-lasting options can minimize waste and the need for frequent replacements. Lastly, explore partnerships with manufacturers who prioritize eco-friendly production processes that minimize harmful emissions and waste.

Incorporating these practices into your project not only promotes sustainability but can also enhance your brand's reputation. As consumers increasingly prioritize eco-friendliness, adopting sustainable practices in your aluminum profile selection can lead to competitive advantages, driving customer loyalty and potentially increasing market share.