In today’s rapidly advancing industrial landscape, the use of Extruded Aluminum Enclosure Profiles has become increasingly crucial for a variety of applications. According to a recent report by Grand View Research, the global aluminum extrusion market is expected to reach USD 135.5 billion by 2027, growing at a CAGR of 5.5%. This growth is driven by the rising demand for lightweight, durable, and corrosion-resistant materials in sectors such as electronics, automotive, and telecommunications. Extruded Aluminum Enclosure Profiles provide exceptional protection for sensitive components while also allowing for efficient heat dissipation and aesthetic flexibility. As manufacturers continuously seek innovative solutions to improve product design and functionality, understanding the best applications for these profiles can significantly influence industry competitiveness and sustainability. This blog will explore the seven best applications for Extruded Aluminum Enclosure Profiles in modern industry, showcasing their versatility and effectiveness in a range of contexts.

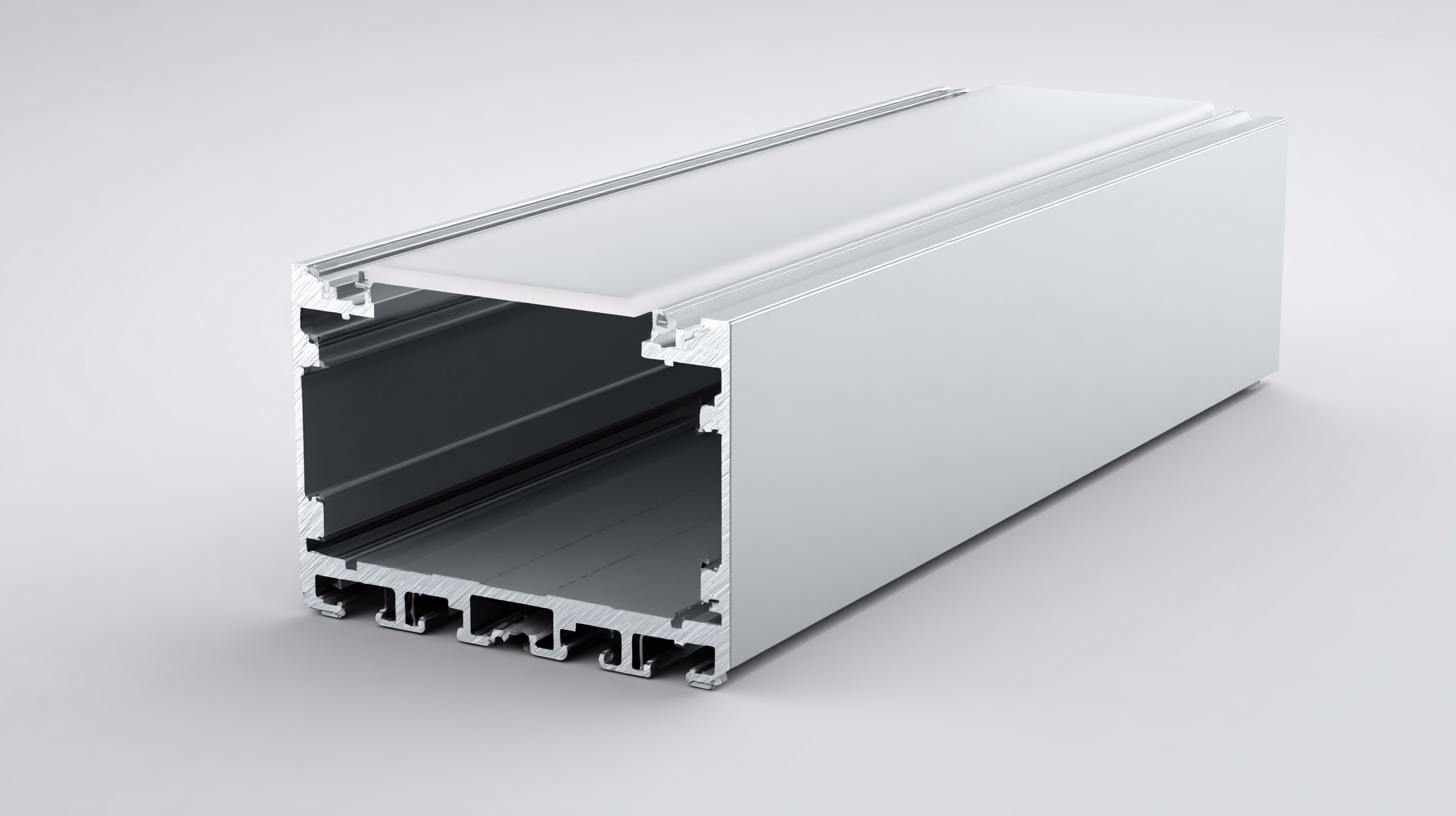

Extruded aluminum enclosure profiles are increasingly becoming essential in electronics manufacturing due to their versatility and strength. One prominent application is in the creation of custom enclosures for various electronic components. These profiles can be tailored to fit specific designs and requirements, allowing manufacturers to ensure that their products are protected from dust, moisture, and other environmental factors. The ability to easily machine these enclosures adds to their appeal, providing manufacturers with the flexibility to create unique shapes and sizes that meet the demands of modern electronics.

Another key advantage of extruded aluminum profiles is their lightweight yet durable nature. This is particularly beneficial in industries where weight is a critical factor, such as in aerospace and automotive applications. Moreover, aluminum’s excellent thermal conductivity makes it suitable for electronic cooling solutions, enabling efficient heat dissipation for sensitive components. As advancements in aluminum extrusion technologies continue to evolve, we can expect to see a broader range of innovative applications for these enclosures in electronics, enhancing both functionality and aesthetic appeal in industrial designs.

Effective thermal management is a crucial aspect of utilizing extruded aluminum enclosure profiles in modern industrial applications. As devices shrink in size and increase in performance demands, the need for efficient heat dissipation methods becomes paramount. Recent studies highlight the significance of scalable and tunable micro/nanostructuring of aluminum surfaces to enhance thermal dissipation. By employing techniques such as chemical etching, the thermal conductivity can be improved significantly, which is vital for modern electronics such as display devices.

Moreover, advancements in additive manufacturing are transforming the landscape of thermal management. Research shows that thermal post-processing techniques can markedly enhance the thermal conductivity of additively manufactured parts, achieving values up to 2.5 times higher than their as-printed counterparts. This is particularly important in sectors like electric vehicle battery systems, where effective thermal management determines overall performance.

Immersion cooling, alongside innovative aluminum-graphite composite foils produced via hot-extrusion, presents new approaches to manage heat effectively in industrial enclosures, ultimately enhancing longevity and reliability in various applications.

Aluminum enclosures have become a cornerstone in modern industry, significantly impacting the longevity and reliability of equipment. These enclosures provide exceptional protection against environmental factors such as moisture, dust, and temperature fluctuations. By utilizing extruded aluminum profiles, manufacturers can create robust and lightweight enclosures that not only safeguard sensitive components but also enhance the overall performance of industrial machinery.

One of the key benefits of aluminum enclosures is their ability to dissipate heat effectively. This thermal management capability helps maintain optimal operating conditions, reducing the risk of overheating and prolonging the lifespan of electrical components. In sectors ranging from telecommunications to renewable energy, the integration of aluminum enclosures has proven essential for ensuring equipment reliability under demanding conditions.

**Tips:** When selecting an aluminum enclosure, consider the specific environmental challenges it will face. Ensure that the enclosure offers a proper ingress protection (IP) rating suitable for your application. Additionally, think about the design; custom extruded profiles can allow for better integration with existing systems, enhancing both functionality and aesthetics. Lastly, regular maintenance checks can greatly prolong the life of the enclosure and its contents, allowing for early detection of potential issues.

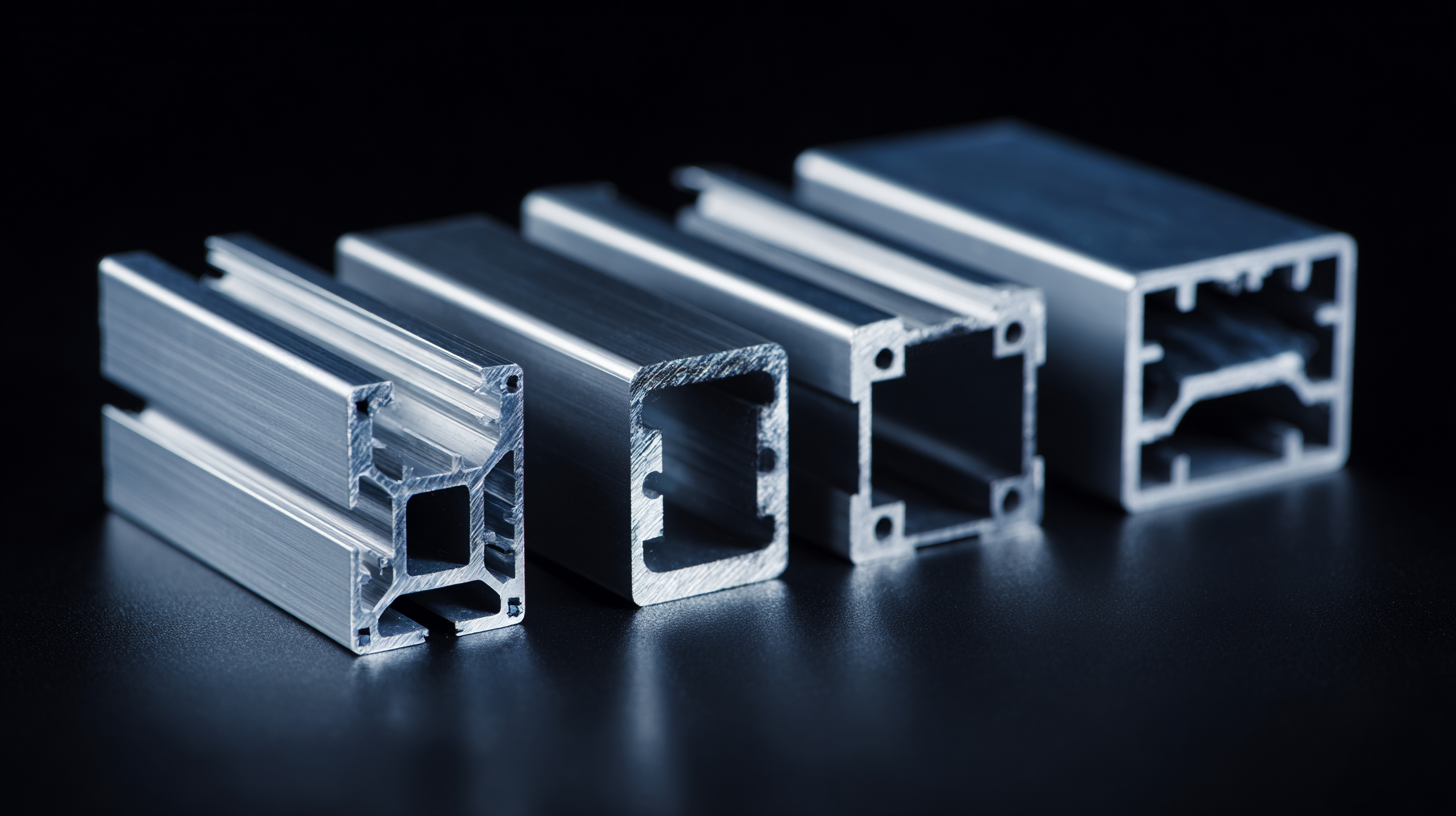

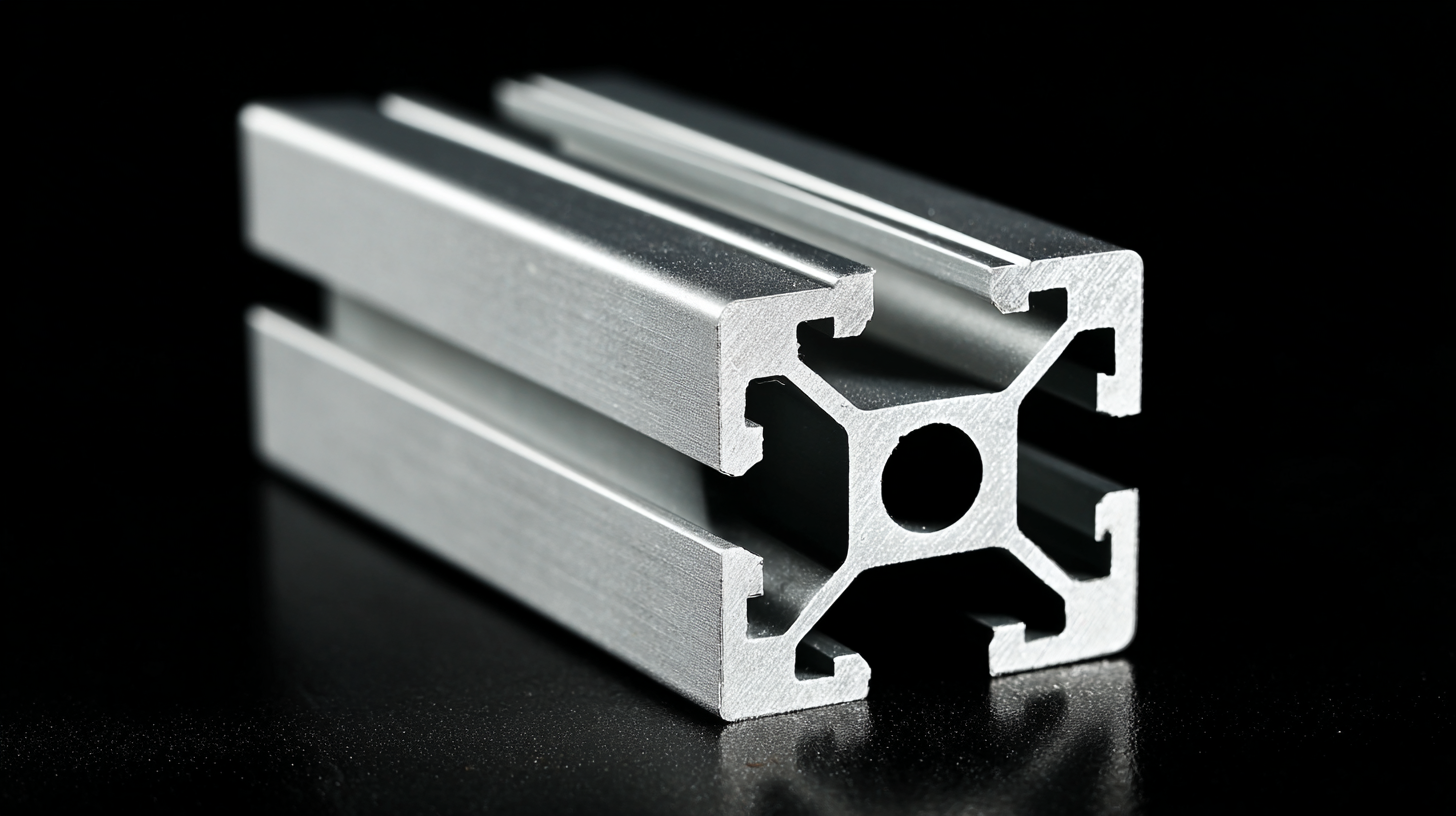

Extruded aluminum profiles have become increasingly popular in modern industrial design, primarily due to their cost-effectiveness. Unlike traditional materials, aluminum profiles can be produced with minimal waste, making them a more sustainable option. The extrusion process allows manufacturers to create complex shapes and sizes with high precision, ensuring that the final products meet the specific needs of various applications. This flexibility not only reduces production costs but also shortens lead times, giving industries a competitive edge.

Furthermore, the lightweight nature of extruded aluminum contributes to lower transportation costs and easier handling during assembly. Industries such as electronics, automotive, and renewable energy thrive on these advantages, as they require materials that are both durable and economical. With aluminum’s excellent corrosion resistance and ability to be finished in various ways, such as anodization or powder coating, it provides additional value, reducing the need for costly secondary processes. Overall, the integration of extruded aluminum profiles in industrial design enhances performance while keeping expenditures in check, allowing companies to maximize their budget without compromising on quality or functionality.

The growing emphasis on sustainability in modern industry is steering the use of extruded aluminum enclosure profiles towards greener applications. According to a report from the Aluminum Association, the global market for aluminum is projected to reach $245 billion by 2025, partly driven by its recyclable nature and energy-efficient production processes. As industries strive to minimize their carbon footprints, extruded aluminum offers a practical solution due to its lightweight properties, which can lead to reduced energy consumption in transportation and operations.

Emerging trends point towards innovations in aluminum alloys that enhance strength while maintaining low weight, catering to sectors such as automotive and renewable energy. A study by the International Aluminum Institute notes that the recycling of aluminum saves up to 95% of the energy required to produce new aluminum from ore. This aspect is critical for industries aiming for sustainable practices, as it not only lowers production costs but also aligns with global sustainability goals. As technology continues to evolve, the adaptability and eco-friendliness of extruded aluminum profiles are set to play a pivotal role in shaping resilient, sustainable industrial solutions.