Aluminum Alloy Profiles are essential materials in various industries. They are lightweight yet durable, making them ideal for construction and manufacturing. According to a recent industry report by Grand View Research, the global aluminum alloy market is expected to reach USD 187.7 billion by 2025. This growth reflects the rising demand for aluminum in transportation, construction, and other sectors.

With numerous options available, selecting the best Aluminum Alloy Profiles for your next project can be daunting. Quality, strength, and cost-effectiveness are key considerations. Inadequate selection can lead to structural failures or increased costs later on.

Understanding specific needs and application requirements is crucial. Not all aluminum profiles are created equal. Some may not meet necessary industry standards, which can compromise safety and performance. Failing to consider these factors may result in project setbacks. Selecting the proper Aluminum Alloy Profiles calls for careful analysis and informed decisions.

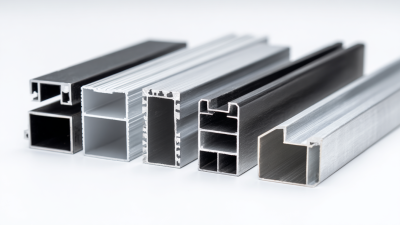

Aluminum alloy profiles are versatile materials widely used in various industries. These materials are known for their lightweight and strength. According to a recent industry report, the global aluminum market is expected to grow at a CAGR of 5.1% from 2021 to 2028. This growth highlights the increasing demand for aluminum alloys across applications.

These profiles serve numerous functions. They range from structural supports in buildings to components in aerospace. The automotive sector also benefits significantly from aluminum's properties. An estimated 20% of vehicle weight reduction can be achieved through aluminum use. However, the choice of the right alloy sometimes poses challenges. Not all aluminum profiles offer the same mechanical properties, which can lead to performance issues.

Designers and engineers must be meticulous in their selection process. The wrong profile can impact project success. For example, using an alloy with insufficient tensile strength can lead to failures. Applications demanding high corrosion resistance must consider alloys suited for such environments. Balancing cost and performance is always a tricky endeavor in project planning.

When selecting aluminum alloys for your next project, the key properties to consider play a crucial role. Strength is one of the most important factors. Different alloys offer varying tensile strengths. The right choice can heavily influence the durability of your final product. If you expect heavy loads, prioritize high-strength options. Lightweight options are tempting but may compromise dura bility in certain applications.

Corrosion resistance is another significant property. Some environments are harsher than others. Alloys with a protective oxide layer can resist corrosion better. Think about the environment your product will face. Moisture and chemicals can rapidly degrade less resistant materials. Appearance can be a factor too, especially for consumer products. An alloy that supports surface treatments can make your project visually appealing.

Formability and weldability are often overlooked. Not all alloys are easy to work with. Some may crack or become brittle during welding. It's worth testing in advance. Always consider how your choices will impact manufacturing. A perfect design doesn’t always translate into reality. Balancing these properties is essential. Reflect on your priorities, as they will guide your decision-making process effectively.

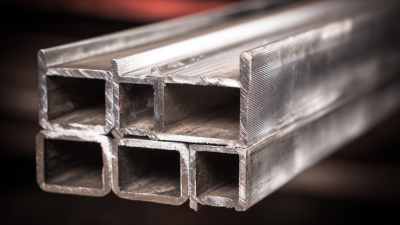

When choosing aluminum alloy profiles for structural projects, one must consider various factors. Aluminum alloys are known for their strength-to-weight ratio. According to a 2022 industry report, structural aluminum can be up to 30% lighter than steel while still providing necessary durability. This makes them ideal for aerospace and automotive applications.

Alloys like 6061 and 7075 are popular in construction. Their mechanical properties make them versatile for different load-bearing structures. A study indicated that 6061 has excellent corrosion resistance, which enhances its longevity in structural applications. However, the choice of profile can significantly impact the overall project design and performance. Some profiles may not meet specific project needs, leading to inefficiencies.

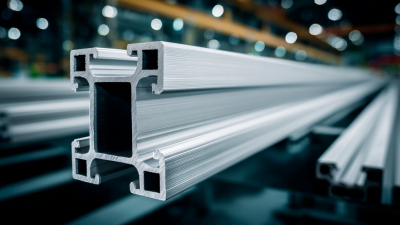

Installation is another aspect to consider. Profiles can be difficult to work with if not properly matched to project requirements. Many fabricators face challenges with cutting and joining methods. Thus, ensuring compatibility with construction techniques is crucial. Inadequate planning can lead to increased costs and time delays, highlighting the need for meticulous preparation before selecting an aluminum profile.

When choosing aluminum alloy profiles, cost and performance must be closely examined. Different alloy compositions offer various mechanical properties. For example, some alloys provide high strength, while others offer excellent corrosion resistance. Understanding these trade-offs is crucial for project success.

Cost also plays a significant role in the selection process. Cheaper alloys might not perform well under stress. They can lead to project failures, resulting in financial losses. Conversely, high-performance alloys may require a larger budget. Finding the right balance is essential.

Understanding the specific requirements of your project can help in decision-making. Are you focusing on structural integrity or weight reduction? Consider the project environment as well. Certain alloys thrive in harsh conditions, while others may not provide adequate longevity. Reflecting on these factors can guide you toward the best choice for your needs.

| Alloy Type | Cost per kg ($) | Strength (MPa) | Weight (kg/m) | Corrosion Resistance (Rating) | Heat Treatable |

|---|---|---|---|---|---|

| 6061 | 3.50 | 240 | 2.70 | Good | Yes |

| 6063 | 3.20 | 220 | 2.60 | Excellent | Yes |

| 7005 | 4.00 | 330 | 3.00 | Moderate | Yes |

| 2024 | 5.50 | 480 | 2.90 | Poor | Yes |

| 7050 | 6.00 | 570 | 3.20 | Moderate | Yes |

| 5083 | 4.30 | 290 | 3.10 | Excellent | No |

| 6005 | 3.80 | 250 | 2.75 | Good | Yes |

| A356 | 5.10 | 310 | 2.95 | Good | No |

| 3003 | 3.00 | 130 | 2.45 | Excellent | No |

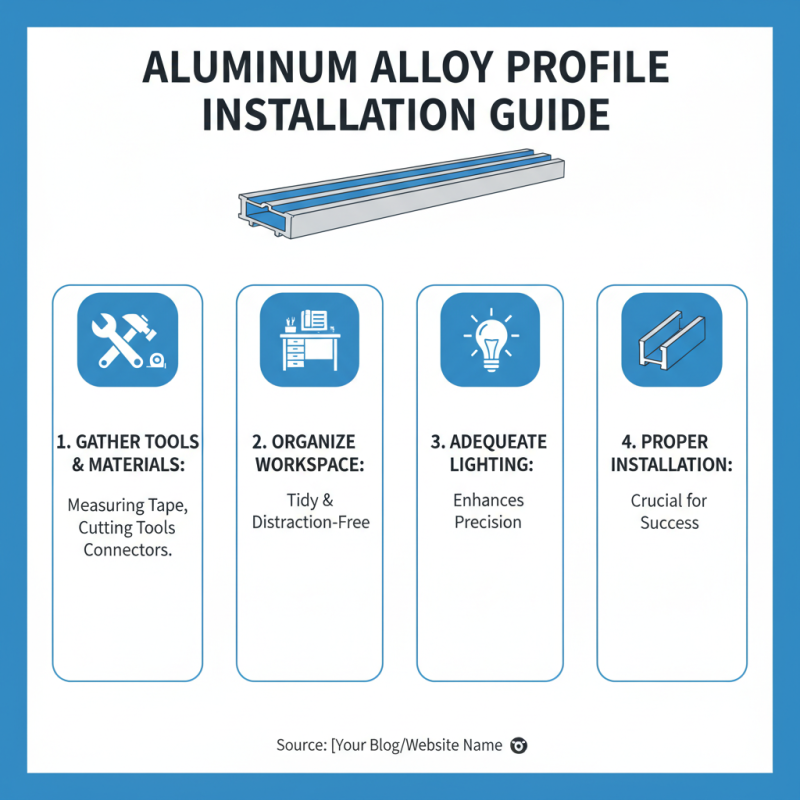

When working with aluminum alloy profiles, proper installation is crucial. Start by gathering the right tools and materials. You will need a measuring tape, cutting tools, and connectors. Ensure that your workspace is organized and free of distractions. Light plays a significant role, as adequate lighting helps maintain precision during measurements.

Consider pre-drilling holes to avoid cracking during assembly. This tip can save you a lot of time and frustration later on. Use clamps to secure the profiles firmly before finalizing any connections. Check your angles frequently; misalignment can lead to costly mistakes. Also, be careful with finger placement while cutting; injuries can happen easily.

Clean surfaces before connecting any profile sections. This practice ensures a strong bond and prevents future deterioration. Finally, review your work periodically. It's easy to overlook minor errors, but they can have significant consequences. In the end, attention to detail is what makes your project successful.