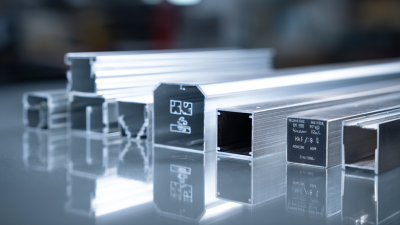

Aluminum moulding profiles have become increasingly popular in various industries due to their remarkable versatility and durability. With advancements in manufacturing techniques, the global aluminum profile market was valued at approximately $56 billion in 2020 and is projected to reach $80 billion by 2027, according to a report by Grand View Research. The benefits of aluminum moulding profiles extend beyond aesthetics, offering practical solutions for construction, furniture making, and automotive applications.

One of the key advantages of using aluminum moulding profiles is their resistance to corrosion compared to traditional materials, making them suitable for both indoor and outdoor projects. Additionally, the lightweight nature of aluminum reduces transportation costs and allows for easier handling during installation. Recent studies indicate that projects utilizing aluminum profiles can save up to 30% in material costs due to their efficient design and structural integrity. As industries continue to seek sustainable options, aluminum moulding profiles also present an eco-friendly choice, being 100% recyclable without the loss of quality. Together, these factors underscore why aluminum moulding profiles should be a top consideration for your next project, maximizing both performance and value.

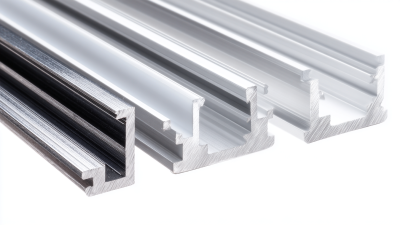

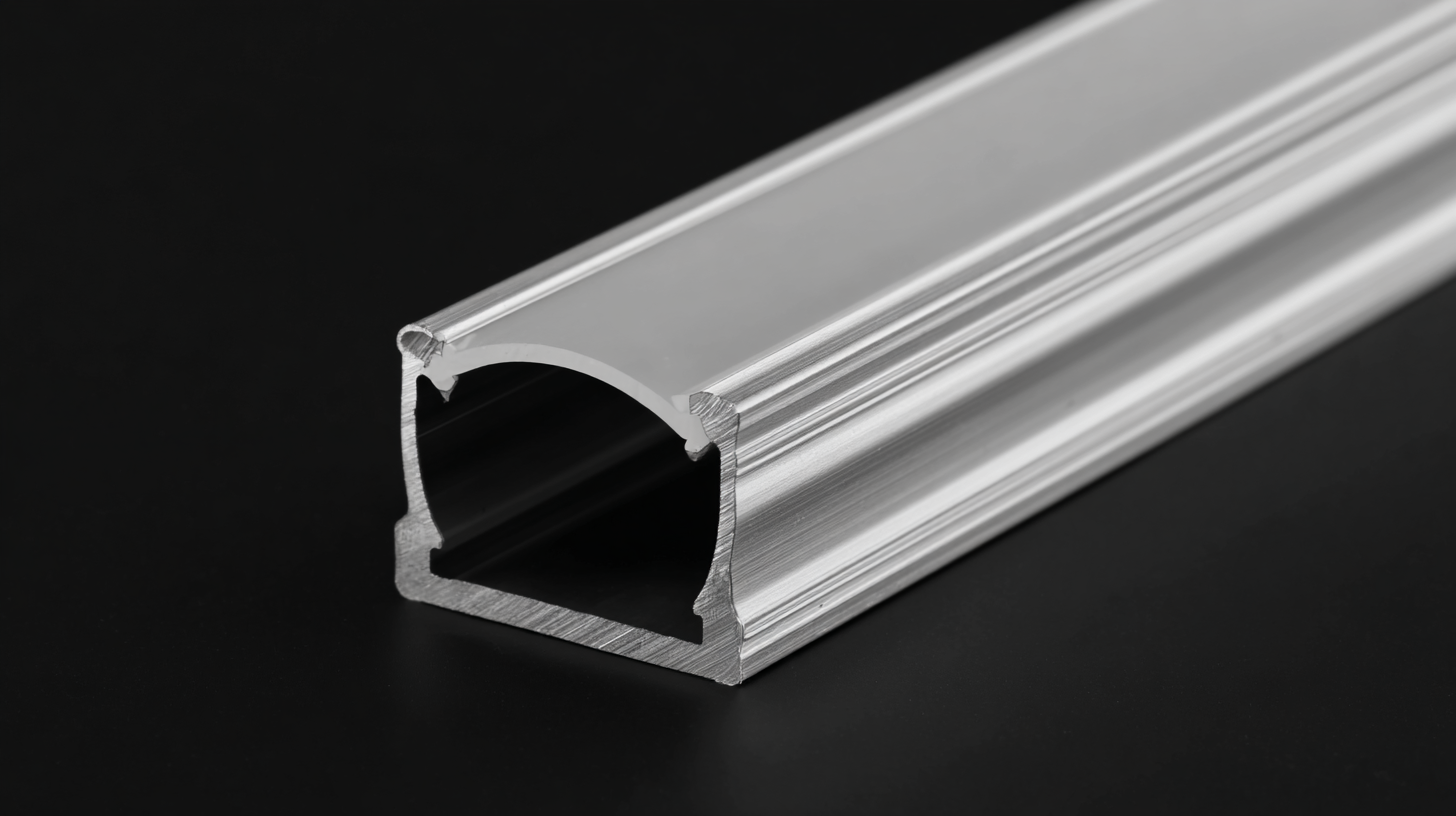

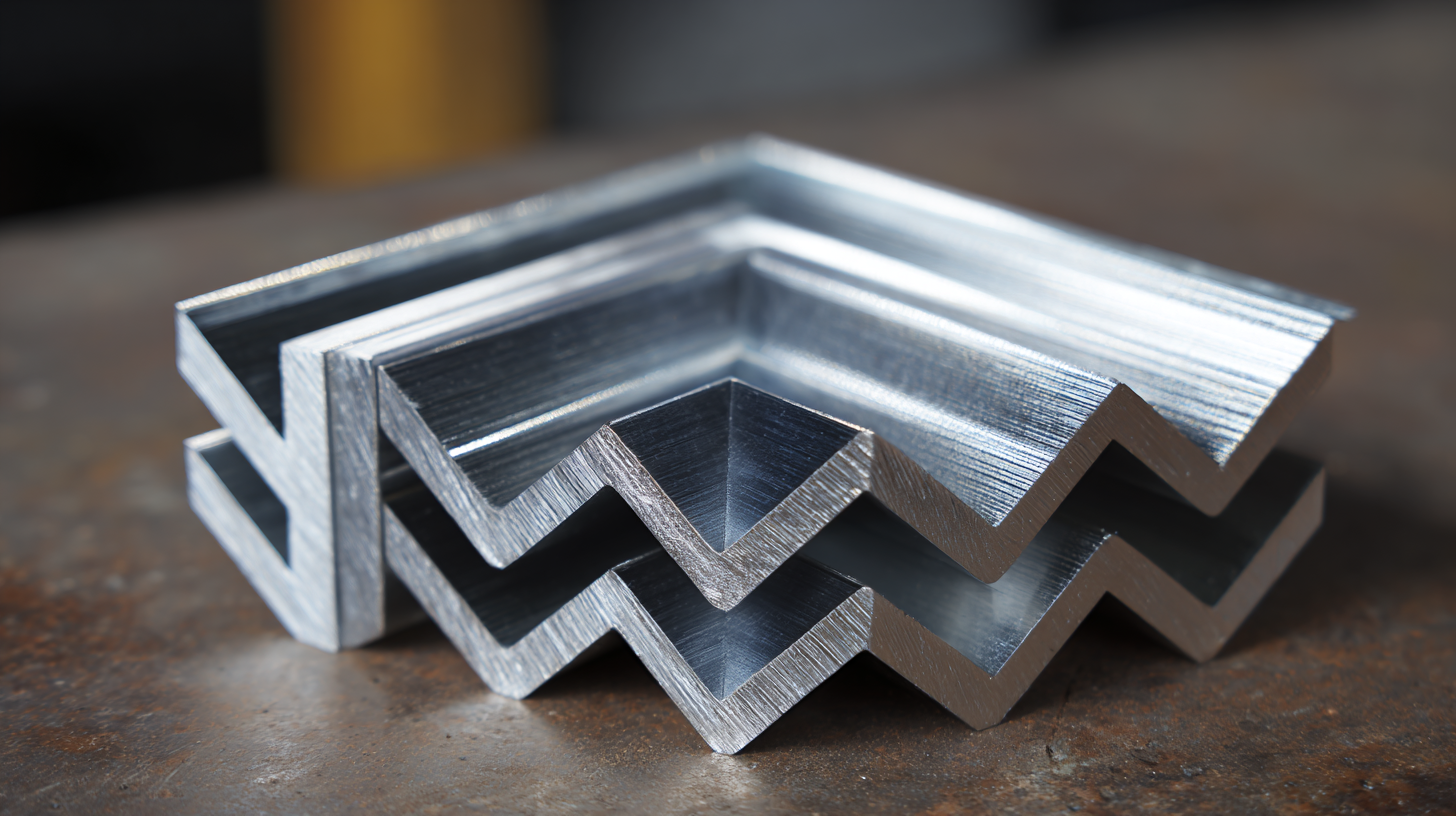

Aluminum moulding profiles offer a combination of design flexibility and aesthetic appeal that is hard to match. Their lightweight nature and malleability allow designers to create intricate shapes and patterns that can enhance the overall look of any project. A report from the Aluminum Association highlights that aluminum’s inherent qualities enable innovative designs while also providing structural integrity. This means architects and builders can push the boundaries of their creativity without compromising on safety and performance.

Aluminum moulding profiles offer a combination of design flexibility and aesthetic appeal that is hard to match. Their lightweight nature and malleability allow designers to create intricate shapes and patterns that can enhance the overall look of any project. A report from the Aluminum Association highlights that aluminum’s inherent qualities enable innovative designs while also providing structural integrity. This means architects and builders can push the boundaries of their creativity without compromising on safety and performance.

In addition to flexibility, the aesthetic versatility of aluminum moulding profiles is noteworthy. They can be finished in a variety of colors and textures, fitting seamlessly into different design themes—from modern minimalist to classic elegance. According to a recent industry study, projects incorporating aluminum finishes are perceived as more contemporary and visually appealing, leading to a 30% increase in property value. Furthermore, metal materials, including aluminum, are increasingly favored in sustainable building designs due to their long-lasting durability and ability to withstand harsh environmental conditions. This trend correlates with the growing demand for materials that not only meet functional requirements but also elevate visual experiences in residential and commercial spaces.

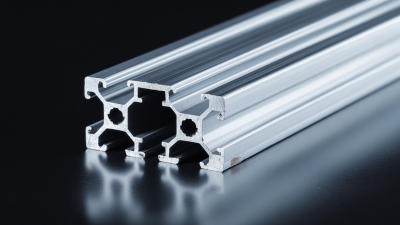

Aluminum moulding profiles have gained significant traction in various construction and design projects, primarily due to their exceptional durability and longevity. According to the Aluminum Association, aluminum exhibits a high resistance to corrosion, allowing structures and designs to maintain their integrity over time even in challenging environmental conditions. This property is particularly valuable in regions with high humidity or exposure to saltwater, where other materials may degrade much faster. A study published by the International Journal of Engineering Research highlights that aluminum can last over 50 years with minimal maintenance, making it a cost-effective choice for long-term projects.

Furthermore, the structural strength of aluminum profiles plays a crucial role in enhancing project longevity. The National Association of Home Builders found that projects utilizing aluminum profiles experience fewer structural failures compared to those using traditional materials like wood or PVC. The lightweight nature of aluminum also leads to easier handling and installation, reducing the risk of damage during transportation and assembly. Ultimately, incorporating aluminum moulding profiles into your next project not only improves durability but also contributes to the overall sustainability of the construction process, as aluminum is 100% recyclable and can be reused without losing its properties.

Aluminum moulding profiles have emerged as a cost-effective solution in various construction projects. According to a report by the Aluminum Association, using aluminum in architectural applications can reduce overall material costs by up to 30% when compared to traditional materials such as wood and steel. This significant reduction is primarily attributed to aluminum's lightweight nature, which decreases transportation costs and simplifies installation procedures. Additionally, the durability and low maintenance requirements of aluminum profiles translate to long-term savings, as projects require fewer repairs and replacements over their lifespan.

Furthermore, a study from the National Association of Home Builders indicates that projects utilizing aluminum moulding profiles can see a return on investment (ROI) greater than 15% due to energy efficiency benefits. Aluminum's reflective properties can enhance insulation performance, leading to notable savings on energy bills. Moreover, the recyclable nature of aluminum plays a crucial role in sustainable building practices, aligning with the growing demand for eco-friendly solutions in construction. Adopting aluminum moulding profiles not only supports cost efficiency but also paves the way for environmentally responsible projects, making it an ideal choice for modern builders.

Aluminum moulding profiles have gained popularity due to their numerous sustainability benefits, particularly their recyclability. Unlike many other materials, aluminum can be recycled multiple times without losing its integrity or quality. This characteristic allows for a closed-loop system where old aluminum products are repurposed into new ones, significantly reducing the demand for virgin materials. In a world increasingly focused on reducing waste and conserving resources, the use of aluminum moulding profiles represents a responsible choice for environmentally conscious builders and designers.

Moreover, the recycling process for aluminum is energy-efficient compared to the extraction and refinement of new aluminum. It typically requires only about 5% of the energy needed for primary aluminum production, substantially decreasing carbon emissions associated with manufacturing. This means that every project utilizing aluminum moulding profiles contributes less to environmental depletion. By integrating these profiles into your next project, you are not only choosing a durable material but also actively participating in the promotion of sustainable practices that benefit the planet.

| Benefit | Description | Recyclability Factor | Environmental Impact |

|---|---|---|---|

| Lightweight | Aluminum is significantly lighter than other metals, making it easier to handle and transport. | 100% recyclable with no loss of quality. | Reduces energy consumption during transport. |

| Durability | Resistant to corrosion, ensuring long-lasting performance. | Can be recycled endlessly without degrading. | Lowers the need for replacement, reducing waste. |

| Aesthetics | Modern and sleek finish enhances the visual appeal of projects. | Can be recycled into new design products. | Supports a circular economy in design. |

| Thermal Conductivity | Excellent conductor of heat, ideal for thermal management applications. | Recycling saves energy and resources. | Decreases reliance on non-renewable resources. |

| Cost-Effectiveness | Lower lifecycle costs due to durability and low maintenance. | Recycling reduces material costs in the long run. | Less waste generation contributes to sustainability. |

| Versatility | Useful across various industries from construction to decoration. | Easily repurposed for various applications. | Minimizes waste through diverse applications. |

| Non-Toxic | Aluminum does not produce harmful substances during production or recycling. | Safe to recycle and reuse. | Promotes safety in manufacturing and use. |

| Energy Efficient | Transportation and production processes for aluminum have become more efficient. | Recycling uses 95% less energy than new production. | Reduces overall carbon footprint. |

| Availability | Abundant supply worldwide; accessible for production. | Recyclable material is easily available in scrap. | Supports sustainable industry practices. |

| Low Maintenance | Aluminum requires minimal upkeep, saving time and resources. | Recycling contributes to longer material life cycles. | Less frequent replacements lead to diminished waste. |

Aluminum moulding profiles are becoming increasingly popular due to their superior performance under extreme conditions compared to traditional materials. When exposed to harsh environments, aluminum displays remarkable resistance to corrosion and thermal expansion, which are crucial traits for projects in diverse climates. For instance, studies highlight that aluminum’s durability makes it an ideal candidate for high-performance applications, including automotive and aerospace sectors, where temperature fluctuations can significantly impact material integrity.

Moreover, advancements in aluminum composites, such as those reinforced with titanium carbide and yttrium oxide, further enhance the mechanical and ballistic properties of aluminum-based products. These enhancements are particularly relevant in industries requiring robust materials for security and safety, such as armored vehicle production. Research indicates that components crafted from advanced aluminum alloys not only meet stringent safety standards but also outperform traditional materials in both weight and strength, paving the way for innovative designs and increased efficiency in structural applications.