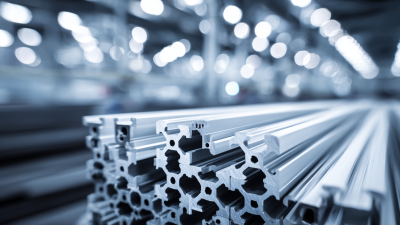

When it comes to constructing a wide range of projects, the importance of selecting the right materials cannot be overstated. Among the various options available, Standard Aluminum Extrusion Profiles stand out due to their versatility and efficiency. These profiles are designed to meet a variety of needs, allowing for a seamless integration into numerous applications, from architectural constructs to functional components in machinery.

One of the key advantages of Standard Aluminum Extrusion Profiles is their lightweight nature, which facilitates easy handling and installation without compromising structural integrity. Additionally, their outstanding strength-to-weight ratio makes them ideal for projects that require both durability and ease of use. The standardized nature of these profiles also means that they come with a range of pre-defined shapes and sizes, streamlining the design and manufacturing processes, which ultimately saves time and reduces costs.

In summary, the integration of Standard Aluminum Extrusion Profiles into your project can lead to substantial benefits. These profiles not only enhance the overall function and appearance of your designs but also provide a reliable and sustainable option for construction. Whether you are embarking on a residential renovation or a large-scale industrial endeavor, choosing these profiles can significantly influence the success and efficiency of your project.

Standard aluminum extrusion profiles offer several advantages that can make a significant difference in various projects across multiple industries. One of the primary benefits is their versatility; these profiles can be tailored for a wide range of applications, from structural supports to aesthetic architectural elements. According to a report from the Aluminum Association, aluminum structures can exhibit a tensile strength of up to 300 MPa, which makes them an excellent choice for lightweight yet durable constructions. This property allows engineers and designers to utilize thinner profiles without sacrificing strength, ultimately reducing material costs and enhancing design possibilities.

Moreover, standard aluminum extrusion profiles boast excellent corrosion resistance, which is particularly beneficial in outdoor and industrial applications. A study published in the Journal of Materials Science highlights that aluminum's natural oxide layer provides a protective barrier against harsh environmental conditions, ensuring long-term durability. This characteristic minimizes maintenance needs and replacement costs, providing an economic edge in project budgeting.

Tips: When selecting aluminum extrusion profiles, always consider the specific mechanical properties required for your application. It’s also wise to collaborate with suppliers who can provide detailed data sheets, ensuring you understand the profiles' performance metrics. Finally, don't underestimate the impact of anodizing treatments; they not only enhance corrosion resistance but also offer a wider array of aesthetic finishes to meet your project design needs.

Standard aluminum extrusion profiles have become increasingly popular across various industries due to their versatility and adaptability. According to a recent report by the Aluminum Association, the demand for aluminum extrusions is projected to grow at a rate of approximately 4.5% annually through 2025, reflecting their expanding role in numerous applications. From construction and automotive industries to consumer electronics and furniture, standard aluminum extrusions provide a robust framework that can be utilized in a multitude of ways. Their inherent lightweight yet durable nature makes them ideal for structural members, allowing designs that meet rigorous safety and performance standards.

The versatility of standard aluminum extrusion profiles is further enhanced by their ability to be easily customized to meet specific project criteria. For instance, in architectural applications, aluminum extrusions can be designed to not only support but also creatively enhance aesthetic appeal, conforming to modern design trends. The versatility extends to thermal and electrical insulation, providing options that cater to energy-efficient systems in residential and commercial buildings. Furthermore, a study by Freedonia Group highlights that aluminum extrusions are particularly favored in industries seeking sustainable materials, as aluminum is 100% recyclable and can help companies achieve their environmental goals without compromising on quality or functionality. This adaptability not only contributes to the lifecycle of products but also supports innovative solutions in demanding applications.

Standard aluminum extrusion profiles are recognized for their cost-effectiveness, making them an ideal choice for a wide range of projects. Their manufacturing process allows for mass production, which significantly reduces costs compared to custom profiles. This affordability does not compromise quality; rather, these profiles provide durable, lightweight, and corrosion-resistant solutions that can withstand various environmental conditions. By utilizing standard profiles, project managers can allocate resources more efficiently, ensuring that budget constraints are met without sacrificing performance.

Furthermore, the versatility of standard aluminum extrusion profiles contributes to their economic advantage. They can be easily adapted for multiple applications across industries, from construction and automotive to electronics and furniture. The availability of a wide range of shapes and sizes means that businesses can find the right solution for their specific needs without incurring additional costs for customization. This adaptability, combined with the speed of production, helps reduce lead times, enabling quicker project completion and, ultimately, faster returns on investment.

This bar chart illustrates the top benefits of using standard aluminum extrusion profiles in projects. The ratings indicate the level of effectiveness of each benefit, showcasing why aluminum extrusions are a preferred choice in various applications.

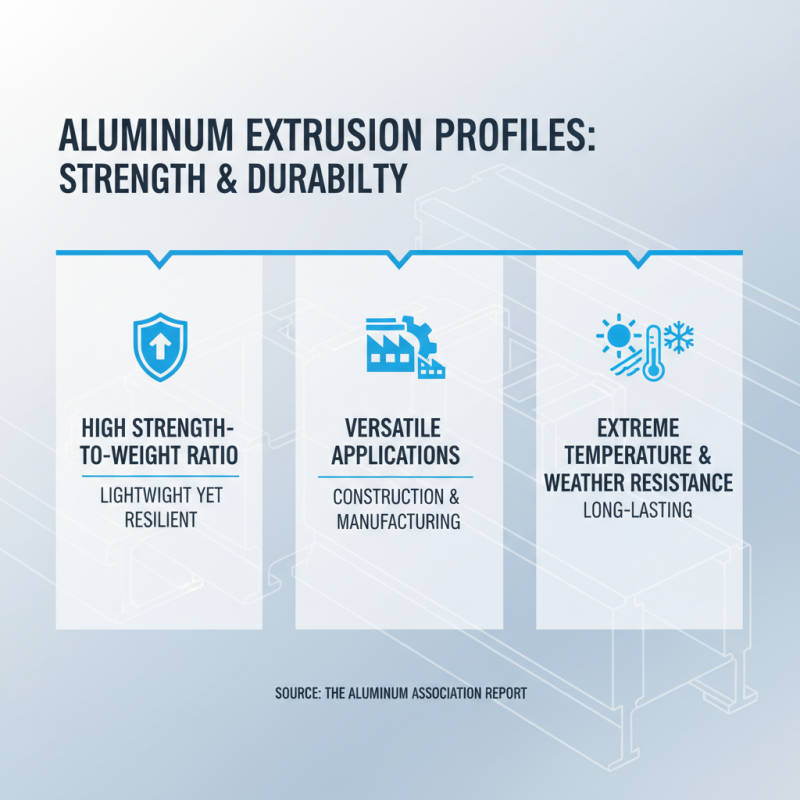

Standard aluminum extrusion profiles offer exceptional durability and strength, making them a popular choice across a variety of industries. According to a report by the Aluminum Association, aluminum has a high strength-to-weight ratio, which means that structures can be lightweight yet still provide the necessary support and resilience. This quality is particularly advantageous in construction and manufacturing, where both performance and efficiency are vital. Additionally, standard aluminum extrusions can withstand a wide range of temperatures and environmental conditions without significant degradation, further enhancing their longevity in projects.

Furthermore, the inherent properties of aluminum, including its corrosion resistance, allow these extrusion profiles to maintain their structural integrity over time. A study conducted by the International Aluminum Institute highlights that aluminum can last for decades when properly treated, resisting the effects of environmental wear such as rust or oxidation. This durability significantly reduces maintenance costs and replacement needs, providing a cost-effective solution for projects with long-term requirements. Thus, selecting standard aluminum extrusion profiles not only ensures immediate strength and reliability but also promotes sustainable practices through longevity and reduced resource consumption over time.

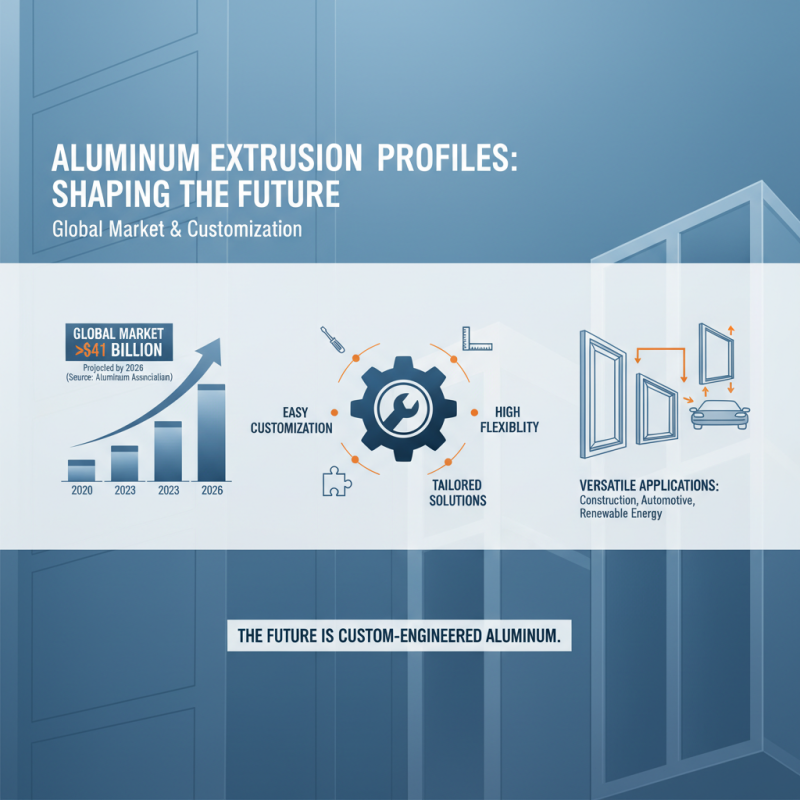

Aluminum extrusion profiles are increasingly favored for various construction and manufacturing projects due to their exceptional ease of customization and modification. According to a report by the Aluminum Association, the global aluminum extrusion market is projected to reach over $41 billion by 2026, driven largely by the growing demands for tailored solutions in various industries. Standard aluminum profiles provide a foundational framework that can be adapted to meet specific project requirements, offering a high degree of flexibility for engineers and designers.

The modular nature of standard aluminum profiles is a significant advantage. These profiles can easily be modified to fit unique specifications, whether it’s through cutting, drilling, or adding components, ensuring that project timelines are minimized. A study from Research and Markets indicated that 65% of industry professionals prefer extruded aluminum for its rapid production times and versatility; this adaptability not only streamlines the design process but also allows for quick alterations during production phases, enabling teams to respond dynamically to changing project requirements. This ease of customization ensures that projects can continue smoothly, reducing costly delays and enhancing overall project efficiency.