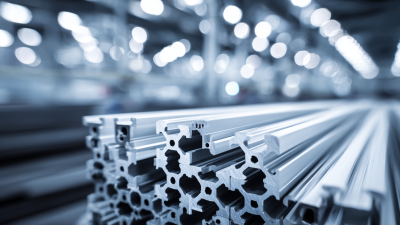

In the ever-evolving landscape of modern manufacturing, extruded aluminum profiles have emerged as a vital component, boasting a myriad of benefits that cater to diverse industrial needs. According to a report by Grand View Research, the global aluminum extrusion market size was valued at USD 92.37 billion in 2021 and is expected to expand at a compound annual growth rate (CAGR) of 6.2% from 2022 to 2030. This growth can be attributed to the lightweight, strength, and corrosion resistance offered by extruded aluminum profiles, making them an ideal choice for sectors such as automotive, aerospace, and construction. Furthermore, the versatility in design and ease of fabrication make these profiles increasingly popular among manufacturers looking to enhance efficiency and sustainability. As industries move towards innovation, understanding the advantages of extruded aluminum profiles is essential for leveraging their potential in contemporary applications.

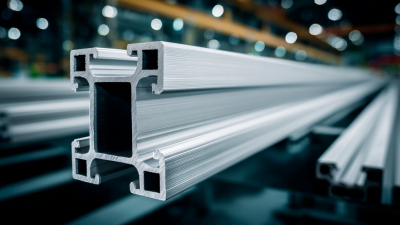

Extruded aluminum profiles have gained considerable attention in modern manufacturing due to their structural superiority over other materials. One of the key advantages lies in their high strength-to-weight ratio. According to the Aluminum Association, aluminum typically weighs only one-third as much as steel but can be just as strong, making it an ideal choice for lightweight applications in industries such as aerospace and automotive. This property allows manufacturers to reduce the overall weight of their products while maintaining or enhancing structural integrity.

Moreover, extruded aluminum profiles offer exceptional versatility in design. With the ability to create complex shapes, manufacturers can tailor profiles to meet specific structural requirements without compromising on durability. A report from the International Aluminum Institute highlights that extruded aluminum structures can withstand significant loads, proving their effectiveness in demanding environments. This adaptability fosters innovative designs that contribute to improved energy efficiency, especially in applications like building facades and window frames, where thermal performance is essential.

Overall, the structural advantages of extruded aluminum profiles make them a crucial component in advancing modern manufacturing standards.

Extruded aluminum profiles have become a cornerstone in modern manufacturing due to their remarkable cost efficiency. One of the foremost advantages of using these profiles lies in the streamlined production process. The extrusion method allows manufacturers to produce complex shapes with minimal waste, as the material is pushed through a die to form desired profiles. This not only saves on raw material costs but also reduces the time and energy expended in crafting components, leading to lower overall manufacturing expenses.

Moreover, the lightweight nature of aluminum contributes significantly to cost savings throughout the production chain. Lighter components mean reduced shipping and handling costs, as well as less energy consumed during the assembly process. Additionally, because extruded aluminum profiles can be fabricated to meet specific requirements without the need for extensive machining, manufacturers can further reduce costs associated with labor and tooling. Overall, these factors highlight how extruded aluminum profiles provide a sustainable and economical solution for modern manufacturing needs, creating efficiencies that resonate throughout the supply chain.

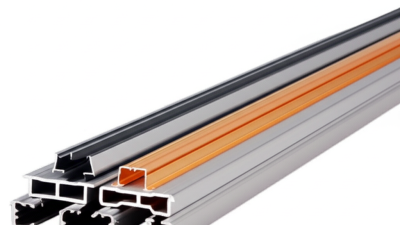

Extruded aluminum profiles have gained significant traction in modern manufacturing due to their unique customization and versatility in design. The extrusion process allows for intricate and precise shapes that can meet a wide array of application needs, making them ideal for industries ranging from aerospace to architecture. This adaptability means that manufacturers can easily design components that fit exact specifications, ultimately reducing material waste and enhancing production efficiency.

When considering extruded aluminum profiles for your projects, here are a couple of tips to keep in mind: First, collaborate closely with your extrusion supplier early in the design phase. This ensures that the design is optimized for the extrusion process, helping avoid costly modifications later. Second, think about the potential for integrating multiple functions into a single profile. By designing multifunctional components, you can simplify assembly processes and save on overall manufacturing costs.

Moreover, the ability to apply various surface finishes to extruded aluminum profiles further enhances their appeal. Whether it's anodizing, painting, or powder coating, these treatments not only improve aesthetics but also provide added durability, corrosion resistance, and increased performance. This means designers can tailor profiles not just for functionality but also for visual impact, meeting both practical and design-focused criteria in manufacturing.

This chart illustrates the various benefits of using extruded aluminum profiles in modern manufacturing. The data shows the percentage of manufacturers who prioritize specific advantages of extruded aluminum in their design processes.

Aluminum profiles have become a cornerstone in modern manufacturing, primarily due to their lightweight yet sturdy nature. With a density of just 2.7 g/cm³, aluminum is roughly one-third the weight of steel while offering comparable strength. This unique combination allows manufacturers to design products that are easier to handle and transport, ultimately reducing operational costs. According to a report by the Aluminum Association, lightweight components can lead to energy savings of up to 30% in transportation, making aluminum a preferred choice in industries such as automotive and aerospace.

One of the key physical advantages of aluminum profiles is their exceptional resistance to corrosion, thanks to the natural oxidation layer that forms on their surface. This characteristic not only enhances the longevity of the products but also minimizes maintenance needs. A study from the European Aluminium Foil Association indicates that aluminum can last over 50 years in outdoor environments without significant degradation, making it a sustainable option for manufacturers looking to enhance their product lifecycle.

**Tips:** When selecting aluminum profiles for your project, consider opting for alloys specifically designed for high strength-to-weight ratios. Additionally, investing in advanced extrusion techniques can further improve the material's properties, ensuring you maximize both performance and durability in your applications.

| Property | Aluminum Profile Value | Comparative Material (Steel) Value |

|---|---|---|

| Weight (kg/m) | 2.7 | 7.85 |

| Tensile Strength (MPa) | 200-300 | 250-400 |

| Corrosion Resistance | Excellent | Moderate |

| Thermal Conductivity (W/m·K) | 205 | 50 |

| Recyclability | 100% | Limited |

The increasing focus on sustainability in manufacturing has led to a significant shift towards the use of extruded aluminum profiles. As a highly recyclable material, aluminum can be repurposed efficiently, with studies showing that over 75% of all aluminum ever produced is still in use today. This remarkable recycling rate not only helps in reducing waste but also significantly lowers energy consumption in the manufacturing process. According to the Aluminum Association, recycling aluminum saves approximately 90% of the energy required to create new aluminum from raw materials, which is a compelling argument for manufacturers looking to minimize their carbon footprint.

Moreover, the environmental impact of using aluminum extends beyond just its recyclability. The production of aluminum profiles through extrusion requires significantly less energy compared to other manufacturing processes. Reports indicate that for every ton of aluminum produced, more than 8 tons of CO2 emissions can be avoided if sourced from recycled materials instead of virgin sources. This efficiency not only makes aluminum an eco-friendly option but also aligns with global sustainability goals, making it an attractive choice for industries committed to reducing their environmental impact. By prioritizing the use of extruded aluminum profiles, manufacturers can enhance their sustainability initiatives while also benefiting from the material's versatility and durability.