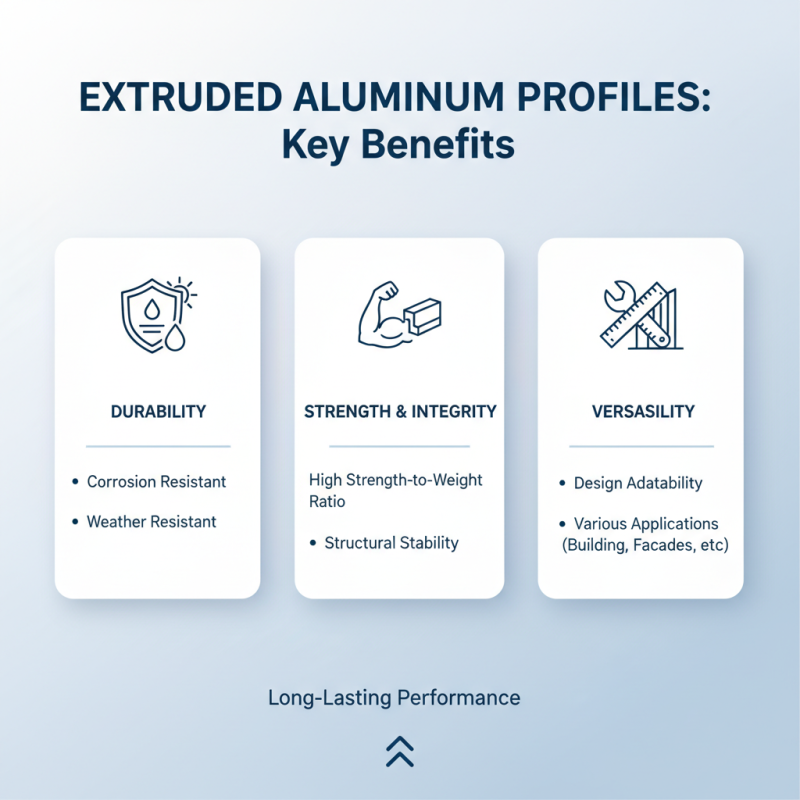

In the ever-evolving fields of construction and design, the materials used play a pivotal role in determining the quality, sustainability, and aesthetic appeal of a project. Among the diverse range of materials available, Extruded Aluminum Profiles have gained significant attention for their unique properties and versatile applications. These profiles are not only lightweight but also exhibit exceptional strength and durability, making them an ideal choice for various structures and designs.

The manufacturing process of Extruded Aluminum Profiles allows for precision in design, enabling architects and engineers to realize intricate designs that meet both functional and aesthetic requirements. Additionally, the corrosion resistance and low maintenance needs of aluminum contribute to the longevity of structures, offering a cost-effective solution in the long run. This introduction explores the top benefits of incorporating Extruded Aluminum Profiles in construction and design, highlighting their impact on enhancing structural integrity, reducing environmental footprints, and providing innovative design opportunities.

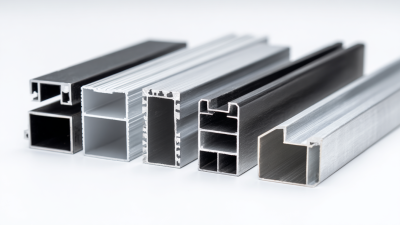

Extruded aluminum profiles have emerged as a preferred material in construction applications due to their remarkable strength-to-weight ratio and versatility. One of the primary advantages is their ability to be custom-designed to meet specific structural and aesthetic requirements. This flexibility enables architects and designers to craft intricate shapes and designs that enhance the aesthetic appeal of buildings while ensuring robust support and durability. Moreover, aluminum’s resistance to corrosion makes it an ideal choice for both indoor and outdoor applications, significantly extending the lifespan of construction projects.

Another significant benefit of using extruded aluminum profiles is their sustainability. Aluminum is a recyclable material, allowing for a reduction in waste and the conservation of resources throughout the construction lifecycle. This eco-friendly attribute aligns with modern building practices focused on sustainability and energy efficiency. Additionally, lightweight aluminum profiles simplify handling and installation, reducing labor costs and time on-site. As a result, the use of extruded aluminum not only contributes to innovative design but also supports environmentally responsible construction methods.

Extruded aluminum profiles have emerged as a preferred choice in the fields of design and architecture due to their remarkable versatility. These profiles can be molded into a wide range of shapes and sizes, allowing architects and designers to innovate and push the boundaries of traditional construction techniques. Their ability to serve various functions—from structural elements to decorative accents—demonstrates their adaptability in numerous applications, whether in residential buildings, commercial spaces, or distinctive installations.

In addition to their flexibility in design, extruded aluminum profiles offer a lightweight yet durable solution that enhances the aesthetic appeal of projects. The material can be easily manipulated, enabling complex designs that maintain structural integrity without compromising visual impact. Furthermore, the wide variety of finishes and colors available for aluminum profiles allows for seamless integration into various architectural themes, making them suitable for both modern and classic environments. This versatility not only meets the creative demands of designers but also accommodates the functionality required in today’s construction practices.

Extruded aluminum has emerged as a cost-effective material in the construction and design sectors. One of its primary advantages is its ability to be produced in a variety of shapes and sizes, allowing designers and builders to tailor solutions to specific project requirements without incurring the high costs typically associated with custom fabrication. The efficiency of the extrusion process minimizes waste, ensuring that more material is put to use, which further enhances the economic viability of using aluminum in building projects.

Additionally, extruded aluminum profiles are lightweight yet strong, which translates to reduced transportation and installation costs. Building with lighter materials often leads to lower foundation and structural costs as well, allowing for more flexibility in design and layout. Moreover, aluminum is resistant to corrosion and requires minimal maintenance over time, reducing long-term operational costs. As a result, using extruded aluminum not only lowers initial expenditures but also contributes to potentially significant savings throughout the lifespan of a building or structure.

Extruded aluminum profiles are increasingly recognized for their substantial environmental benefits in sustainable construction. These profiles are made from aluminum, a material known for its high recyclability—approximately 75% of all aluminum ever produced is still in use today. This remarkable statistic illustrates the longevity and sustainability of aluminum as a construction material. Moreover, using extruded aluminum can significantly reduce the overall carbon footprint of a building. Research from the Aluminum Association indicates that aluminum’s lifecycle can produce fewer greenhouse gas emissions compared to traditional materials like steel and concrete, especially when considering efficient production methods and recycling practices.

Incorporating extruded aluminum profiles in building designs not only enhances energy efficiency but also promotes sustainability. For instance, aluminum's natural ability to insulate can lead to lower energy consumption during a building's operational phase. According to a study by the International Aluminum Institute, buildings that utilize aluminum frameworks reduce their energy needs by up to 20%. This reduction translates into significant cost savings over time, making it a wise choice for environmentally-conscious designs.

Tips: When considering extruded aluminum for your construction projects, always prioritize sourcing from suppliers that adhere to sustainable practices. Additionally, combining aluminum profiles with other green materials can further enhance environmental benefits, making your construction project even more sustainable. Embrace innovative designs that maximize the use of extruded aluminum while minimizing waste and energy consumption.

| Benefit | Description | Environmental Impact |

|---|---|---|

| Recyclability | Aluminum profiles can be recycled indefinitely without loss of quality. | Reduces landfill waste and conserves natural resources. |

| Energy Efficiency | Aluminum has a high thermal conductivity, enhancing energy performance. | Helps lower energy consumption in buildings. |

| Lightweight | Easy to transport and install, reducing transport emissions. | Minimizes carbon footprint during construction. |

| Durability | Resistant to corrosion, weathering, and wear. | Lowers the need for frequent replacements, saving materials. |

| Design Flexibility | Extrusion allows for complex shapes and designs. | Encourages innovative design solutions for sustainability. |

Extruded aluminum profiles have become a popular choice in construction and design, particularly for their exceptional durability and strength. The structural integrity offered by these profiles is crucial for ensuring long-lasting performance in various applications. With their resistance to corrosion and an excellent strength-to-weight ratio, extruded aluminum profiles provide a solid foundation for building frameworks, facades, and other critical components. This means they can withstand harsh environmental conditions, making them ideal for both indoor and outdoor use.

When considering the incorporation of extruded aluminum profiles in your projects, it’s essential to prioritize the proper selection and installation methods. Ensure that the profiles are engineered to meet the specific load requirements and environmental conditions of your project. Regular maintenance checks can also enhance the longevity of these structures; simple cleaning and inspection can prevent common issues related to wear and tear.

Tip: Always consult with a structural engineer to determine the best thickness and shape of aluminum profiles for your specific application. Additionally, consider utilizing anodized finishes to further improve corrosion resistance and aesthetic appeal while maintaining structural integrity.